Plastic molding for custom-made products

Through casting, you can get plastic products of any complexity and in any quantity through plastic injection molding machine in china. Customer-oriented businesses are involved in custom-made plastic injection molding from one-off production to mass production.

Process of plastic injection molding machine in china

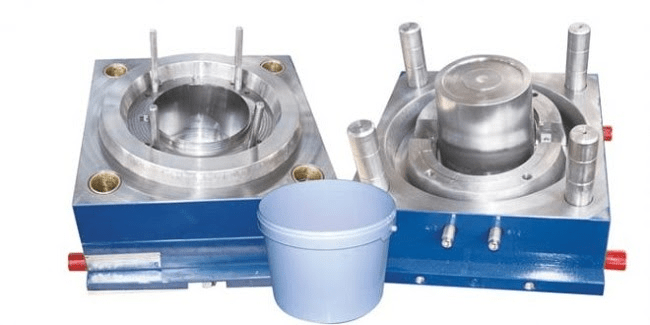

Plastic injection molding machine in china is the process of molding plastic products using a rigid former or a high pressure injection mold. The plastic molding technique makes it possible to produce objects with any shape and size, as well as with a variety of design possibilities. Moreover, products can be both simple and very complex in design.

This type of processing of plastic materials is the most common production method. Even car parts, 3D models and other polymer products are manufactured using plastic injection molding.

Casting and alternative manufacturing methods for plastic products

Today, the production of plastic injection molding machine in china is one of the most profitable and developing business units. Among consumers, these products have value for their inexpensive cost, long-term use and lightness. Anything is easy to make from plastic. Similarly, these are furniture parts, and full-fledged furniture products, kitchen utensils, garden accessories and much more.

Naturally, China is the leader in the manufacture of various products from plastic raw materials. The improvement of this industry in our countries slows down due to the large start-up investments. Furthermore, these come even when the primary production base is formed.

Basically, most of the funding goes to the purchase of the necessary equipment: Injection molding machines, molds, etc.

A variety of techniques for the manufacture of plastic injection molding machine in china:

Here are some techniques of plastic injection molding machine in china.

- Vacuum forming;

- Blowing technique;

- Extrusion method;

- Injection molding of plastics.

Principles of formation of prices for plastic products

Mainly, prices are formed depending on the type of plastic material common, on the laboriousness of the process of creating a mold and on the volume of manufactured products.

Despite the considerable number of methods for the manufacture of plastic products, plastic injection molding machine in china has been considered the most profitable and common molding method for many years. Casting can produce products, both in a single copy and in a mass version.

Plastic injection molding machine

The main factor that affects plastic molding is heat. With the help of high-quality heating elements, you will ensure even heating along the entire path of the plastic melt.

Plastic injection molding technology plays a very important role in the context of the growing plastic molding industry, meeting the increasing demand for plastic products of consumers. In this article, we will learn about plastic injection molding technology in today's plastic manufacturing companies and businesses.

Plastic injection by manual method

Manual injection molding is the oldest plastic injection method in the plastic injection industry. There, the plastic material will be heated in the barrel, the molten plastic is then put into the mold, after cooling, and the product will have the shape of the mold. All of the above processes perform manually, commonly applied to small processing units, with many limitations in terms of qualifications, machinery and production costs.

Manual plastic injection applies in mold processing, turning, milling, grinding, and welding. This method brings about low production efficiency, but with a reasonable level of processing and suitable facilities. Moreover, it is still possible to produce high-quality products. With simple mold structure, low production cost, low product cost, plastic injection molding machine in china can still grow strongly.

Plastic injection molding technology and application

Currently, in production plants, the application of modern plastic injection molding technologies helps to produce a large number of quality and homogeneous plastic products without consuming much time and human resources.

Hard plastic injection molding technology

Plastic injection molding technology allows the production of hard plastic products with the following process:

Step 1: Melt the plastic material under the action of temperature

Step 2: Moreover, the molten plastic is led into the mold cavity under the effect of high pressure

3: Similarly, the mold closes and clamped to shape the product

Step 4: Cooling, the plastic solidifies to a mold-like shape

Step 5: Furthermore, the mold opens; the formed plastic product eject from the mold

Use of plastic products

The products come from hard plastic materials with good electrical insulation, heat insulation, high hardness, plastic injection molding machine in china and durable in use. Commonly common hard plastic products include household appliances:

- office furniture

- Similarly, furniture

- plastic machinery

- Furthermore, plastic bottles

- plastic food containers

- Moreover, water pipes

- In addition, electrical covers phone.

Plastic injection molding technology

Plastic injection molding technology basically has the same process as hard plastic injection, but is different in step 4, for plastic resins, the process of heating and cooling will repeat many times. This plastic injection molding technology is now being common more and more widely. Similarly, this creates products with excellent quality and high aesthetic value.

Plastic products are popularly applied in the field of interior decoration, automobile manufacturing, and phone accessories. In addition, plastic injection molding machine in china creates products common in industries that require high precision, optical and electronic products.

Transparent plastic injection molding technology

Transparent plastic, also known as crystal plastic, transparent plastic injection molding technology is basically no different from flexible plastic and hard plastic.

Moreover, transparent plastic has the characteristics of lightness, toughness, very high hardness. Moreover, it is especially easy to shape. However, the transparent plastic injection process is more technical. Similarly, this requires higher injection pressure and temperature.

Summary plastic injection molding machine in china

The pressure must not be too high, to avoid deformation of the product and difficulty in ejecting the product. Plastic injection molding machine in china is common in the production of all kinds of products. Furthermore, it happens in daily life and in the industrial field such as: safety glasses, helmets, containers, car light covers, shields thermostat, temperature sensor...