All Services

Why Choose ACE

Your Reliable One-Stop Shop for your Mold and Plastic Needs

Professional Engineer & Design team |

Professional Project Management Team |

Professional mold manufacture and mold assembly team |

Professional Document Control and Logistics team |

|

|

|

|

| Mold design and manufacturability analysis

Product Design for manufacturability analysis Product and Mold Processing feasibility analysis New product development and manufacturability analysis |

Mold and plastic manufacture followed up by a specially assigned person

Mold and plastic testing and adjustment followed up by a specially assigned person Mold and plastic optimization and processing followed up by a specially assigned person Mold and plastic after sales service followed up by a specially assigned person |

Professional Mold Components manufacture team

Professional Mold Assembly and Mold testing team Professional Mold Surface Polishing and Lettering team Professional Mold Components and Molding parts inspection team |

Administrator for each project drawing data collection

Specially assigned team to provide customer the best and cheapest logistics solution Strategically chosen logistics company to handle customer’s logistics issues Specially assigned personnel to track each package and shipment for customer project |

Spend the least effort to get your most satisfied mold plastic product

Spend the least money to make your most satisfied mold plastic product

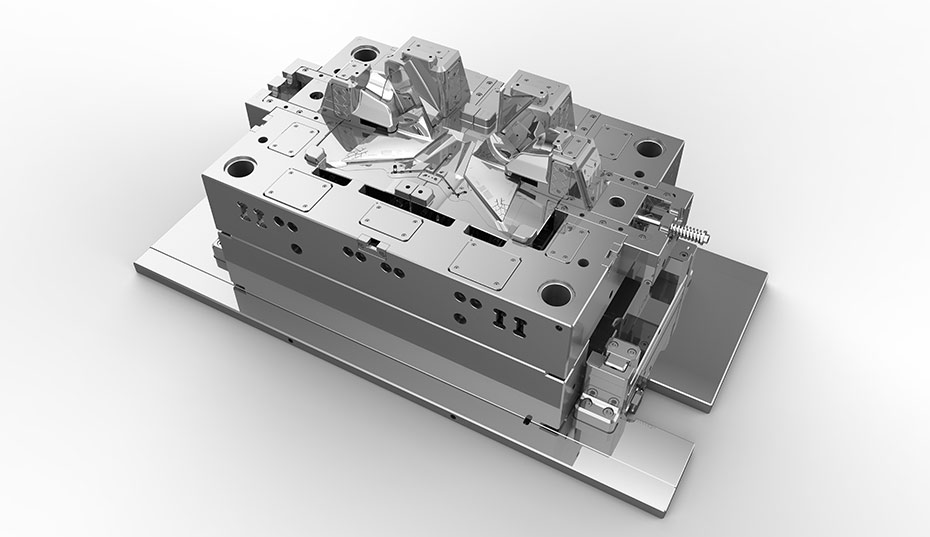

What is Plastic Injection Mould Making?

ACE produces a wide range of injection moulds from single cavity SPI class 103 moulds to multi-cavity SPI class 101 moulds. Our mould types include standard moulds with side actions and lifters, hot runner Moulds, unscrewing moulds, 2K moulds and insert type over moulds.

Equipped with Roeder's high-speed CNC, Makino EDG3 precision EDM, and highest repeat-positioning accuracy Erowa system, etc. ACE Mold can reach an annual output of over 300 sets of plastic production moulds weighing up to 10 tons and handles 30 sets of moulds at one time.

Our moulds are constructed to precise DME and Hasco mould standards. We can provide any required brand name mould components such as HASCO, DME, PROGRESSIVE, MISUMI, Parker, and many others.

What Areas is Plastic Injection Mould Making Best Applied To?

Some of the examples are:

- Automobile parts

- Household appliances

- Medical devices

- Housings for electronics

- Farming tools

- Packaging such as lip balm containers, caps, and so on.

- Daily use combs, caps of bottles, wire insulations etc.

China Plastic Injection Moulding Two Shot Mould Manufacturer

Table of contents ace-mold 1 Two Shot Injection Moulding 2 Two Shot Mould Manufacturer 3 Benefits of ...

Now, take your business to the next level! Click the Mail button to send us your requirements and Request for Quote.

* We Will Reply To You Within 24 hours. Tel: +8613713653495, our working days are Mon. to Sat., Beijing Time: 9:00~18:00.