How to find soft plastic molds manufacturing company?

Nowadays it is possible to find soft plastic molds practically by performing a search in an internet search engine. This makes it easier for people to be able to more easily contact companies and professionals they need. Despite this promoted facility, it is important to be aware of the quality of service and the reputation of the company or professional.

So, remember to do some research to understand if such a plastic manufacturing company is really trustworthy. A good tip is to search for reviews and comments from customers you will be attending. This way, you will be ensuring that your order is delivered with the quality you expect, following all the notes made at the time of project preparation.

Free Consulting

We, develop plastic boxes and cabinets for electronic equipment using a differentiated technology, without the need to use soft plastic molds and special tools. It is thanks to this technology that our plastic manufacturing company offers great solutions with low initial investment cost, production of small and medium scales, according to the customer's request.

We have a highly experienced and trained team, capable of developing or even modifying projects from plastic cabinets to existing electronics with ease and quality assurance. In addition, as a reflection of customer satisfaction and continuous improvement of products and services we were awarded the ISO 9001:2015 Quality Management System certification.

Advantages of soft plastic molds

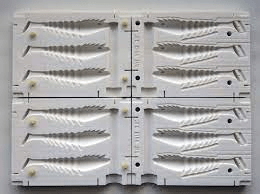

As we are a company whose process is differentiated, we create and develop totally unique projects that have flexibility for the soft plastic molds, with curves and radii that meet all existing needs. For you to understand a little better about our services, we have gathered below a series of advantages provided by our technology. Check out:

- Low investment;

- Fully customized design;

- Moreover, Changes made with ease;

- Agile production;

- In addition, Production without molds.

Ø Low investment

As our technology does not require the existence of special soft plastic molds and tools, the investment for production becomes below what is considered conventional. Therefore, it is possible to carry out from the simplest to the most complex projects. In addition, this comes without having to worry about large differences in values.

Ø Fully custom design

We are aware of the importance of understanding the technical and marketing needs of each client who seeks our services. After all, each product measures and specific needs related to details such as holes, towers for the components to be fixed. These spaces for USB inputs, connectors and many other types of particularities.

Ø Easily made changes

It is normal that changes and adaptations are necessary throughout the development of the project in order to correct some detail or even release updates to versions of the same product. By utilizing our production technology that does not require special molds and tools, our plastic manufacturing company makes these changes much simpler to carry out.

In addition, there is also the financial factor, since as no high-cost soft plastic molds are common. The change process does not usually have a financial impact on production.

Ø Agile production

The machines we use in the production of plastic boxes and cabinets are programmed through specific software. These are capable of "translating" the project carried out in Autocad. This software is widely common for the preparation of technical drawing pieces and three-dimensional models. In this way, we guarantee more agility in the process and, consequently, faster delivery of parts to our customers.

Have bespoke plastic parts with us!

In this content you can see what a plastic manufacturing company does and why hire this type of service. In addition, we show which differences usually have companies that carry out production with soft plastic molds and those that do not use molds in their production process.

Afterwards, we shared how to find plastic manufacturing company options and took the opportunity to introduce ourselves and show, in detail, all the advantages that our technology offers our customers.

What is plastic injector?

Plastic Injector is a company foccommon on customizing plastic products such as cabinets for electronics. This type of service is the right bet for companies in the electronics segment that are eager to highlight their products with the customization of plastic cabinets and boxes.

Soft plastic molds machine is a strategic solution for companies in the electronic project development sector for their business, since personalization is a factor that makes a difference in the marketing of products. Therefore, organizations in the electronics sector that want to be more competitive in the segment invest in a plastic injection company.

How plastic molding machine works?

In addition, investing in a plastic injection company facilitates the internal processes for developing electronic solutions. This contributes to the improvement of projects. You will understand how a soft plastic molds machine helps to facilitate electronic product development processes; see other benefits generated by the investment and more. Check out the following topics:

- Plastic injection molding machine: understand how the process works

- Reasons to Invest in Plastic Parts Injection Service

- How Injection Service Helps Improve Your Electronics Project

- Savings generated by investing in an injected plastic factory

- Plastic Injection Service Goes Beyond Design

- Why is customization a necessary investment?

- reference in custom electronics cabinets

Soft plastic molds machine: understand how the process works

A soft plastic molds machine in line with market needs such as Acemold works with automated processes. In this technological machines such as CNC are common to customize electronic cabinets.

Thermoplastic injection is a modern and effective solution for those who work with electronic products and are looking for their customization. Therefore, their daily professional life becomes more practical. Learn more about this procedure, a company specialized in its execution.

Nowadays, most products made from plastics go through the thermoplastic injection process, a type of technology that aims to enable precise fittings, according to the project.

Summary

For this reason, the number of companies that work with this type of raw material. This need to take advantage of the injection of thermoplastics has grown significantly.

CNC machines work with computerized numerical control. Moreover, this results in plastic parts injection procedures without the need to use molds. This feature promotes faster product preparation.