Good plastic company features such as versatility, malleability and durability, in addition to being 100% recyclable. Thus make plastics fundamental to everyday life and social development. In their various applications, these products offer hygiene, health, comfort and well-being, safety, economy, practicality, in addition to excellent cost-benefit that’s why plastic product development industry is among top industries.

Plastic Injection Service Goes Beyond Design

Anyone who invests in a plastic injection company, rather than ensuring a unique design needs modern skills. This obtains other highly important advantages for the good acceptability of the product in the market, such as:

- Safety;

- Durability;

At acemold, the injection process for plastic parts is designed beyond personalization, in which companies have the security of having efficient electronic cabinets for the use of components and parts.

As such, this means that all boxes and cabinets have holes for the passage of connectors and other electronics designed to ensure the highest level of reliability.

In addition, injected plastic parts have durability that is another relevant issue in the marketing aspect.

What is the importance of plastic product development industry?

One of the main functions of plastics is to protect. Plastics protect the food we eat, from its production, through storage, until it arrives at our table, through packaging. It is present in water supply systems, as well as in basic sanitation, preventing diseases.

And imagine medicine without plastics. Plastic is present from the simple dressing, through disposable utensils (syringes and blood bags). It comes to catheters, prostheses and modern artificial hearts. It is what guarantees hygiene, protection and an increase in the population's life expectancy.

Role of Plastic product development for environment

Plastic product development also protects the environment. They prevent, for example, contamination of soil and groundwater and prevent erosion when common in the form of blankets and coverings. Present in architecture and construction, they offer, in addition to better cost-benefit, reduced energy use, reduced waste, among other advantages.

Benefit of plastic product development

An example of this is the application on windows. The first USA study on eco-efficiency of windows carried out shows that plastic products are more eco-efficient. This comes with better environmental performance in 10 of the 11 categories analyzed.

Also, the reduction in the weight of products and packaging, obtained by plastic product development, made the need for fuel. It is for their transportation to be lower, which generates less emission. The vehicles themselves have become lighter with plastics and thus consume less fuel and reduce emissions.

Applications of Plastic product development

There are many applications where plastics are environmentally friendly. Not everyone knows, for example.

The material also replaces animal leather in several applications. Not to mention the presence of plastics in computers, tablets, cell phones, TVs, among others.

Plastic product development companies are able to manufacture cases and cabinets for the most varied types of parts. How about knowing more about the topic and also checking where and how to hire the service? Keep reading this post. From electronics, hospital, laboratory equipment, parts from the automotive sector, all these have some component made up of the material.

What a plastic product Development Company does?

A company of this type has the function of producing plastic parts with high precision, providing practicality for projects and ensuring safety for the electronic parts that most of the time composes them.

It is thanks to technologies developed by professionals such as the plastic manufacturer, for example. These companies can outsource this type of service, saving time and investment.

Why do you need a professional plastic product development company?

After all, without the existence of this type of service, it would be necessary to purchase the machinery common in the manufacture of made-to-measure plastic product development.

Similarly, you need to hire specialized professionals to operate the equipment and the entire production. With the help of a plastic manufacturing company, the project goes through a process that starts with the project.

What types of machines are required for Plastic product development?

After deciding how the project should be executed, the parts go through manufacturing, which is when specific machines are common for this type of production. Most of the time, CNC machines are common.

It is important that the plastic manufacturer's machines are periodically overhauled to ensure that the machining of flat thermoplastic sheets is properly carried out.

After being produced, the parts go through some finishing steps, some manual and others performed by automatic machines. Moreover, this ensures that the part is delivered according to the design chosen.

With this action so incisive and relevant in our daily lives, it is necessary to have a harmonious coexistence between the consumption and disposal of plastics.

Are plastics recyclable?

It seeks to strengthen society's relationship with plastic product development, especially with post-consumption. Similarly, we have been working to disseminate correct information about the:

- Applications

- characteristics and

- benefits of these products

This comes in addition to promoting the 3Rs –

- Waste Reduction

- Reuse and Recycling

- to disseminate good plastic consumption and disposal practices.

Not everyone knows, but plastics are 100% recyclable and the recycling industry in China has grown year after year, generating jobs and income. Today, the country recycles around 20% of its plastic production, more than the European Union average, and there are perspectives of increasing this activity, based on the increase in selective collection.

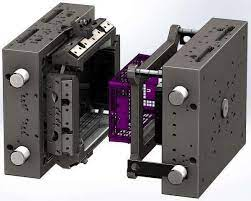

What is the difference between plastic manufacturer with or without molds?

First, it is important to understand that the fact of using or not molds for the parts to be produced varies according to the manufacturer. Therefore, it is important to talk in advance with the company or professional in the area to understand how the parts manufacturing process is carried out.

Reasons to Invest in Plastic Parts Injection Service

In addition to the agility of the production process of a reputable plastic injection company, there are other reasons to invest in the service.

One of them is the Better service

A good plastic product development company designs out according to each request. This makes it possible to obtain cabinets and boxes for electronics in a different model.

Another reason to invest in a plastic injection company is that it is easy to make changes when we need it. Modifications or corrections are often necessary.

Summary

In plastic product development production without mold, the modifications of the parts are usually simpler and faster. Similarly, the initial cost is generally lower, making any type of project feasible. In the case of productions with molds, it is common for them to take a little more time and end up costing higher values, due to the fact that they need more specific tools.