The principle of injection molding

Injection molding or plastic injection is a way of using plastics to create a room. If you want to know the ans of question plastic injection molding companies near me then this article is for you. It consists in softening by means of heat a thermoplastic material to make a piece successful. For the execution of your plastic objects, it must carry out by plastic injection.

It has the possibility of mixing with an additive to give different mechanical properties and dye to create different shades. Moreover, plastic injection is common for technical applications and consumer products.

It seems the best production method for manufacturing identical parts at a high rate. The injection mold appears to be the centerpiece of the principle of plastic injection molding.

What is the importance of design?

Before finding plastic injection molding companies near me you must know about design. Similarly, there are a few design details that should be taken into account. This serves to reduce the risk of appearance abnormalities or other incidents. It is necessary to compete on the wall thickness from the design phase and to hollow out the thick part. Then process the undercuts.

How does injection molding work?

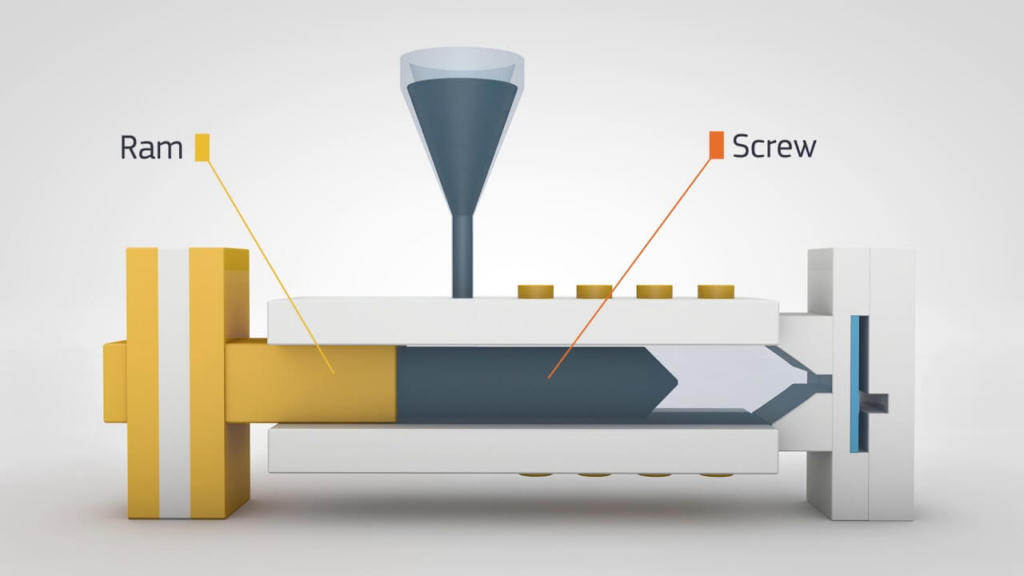

This approach has three processes, including the manufacture of the prototype which will serve as a reference thereafter. Plastic injection molding comes with a feed of thermoplastic materials in the form of granules. It is necessary to load the granules in a cylinder, and the injection screw transports in the mold. Then, they turn into a viscous state.

There are many plastic injection molding companies near me are working that’s why I know after the material has melted, the liquid injects under high pressure into the mold. Thanks to the speed and pressure, the part takes the desired shape. After cooling, the material takes a solid form and of aesthetic quality. Finally, just open the mold to eject the manufactured parts.

The advantage of injection molding

Plastic injection molding companies near me can produce a wide range of products for many industries. Various products like consumer products, toys, aerospace, medical equipment, plumbing, automotive are included. Plastic injection is also differentiated by its speed of transformation. Indeed, the machine performs the work automatically and at high speed.

The injection by pressure of the viscous material allows the latter to obtain the impression of the mold more quickly. Once the object cools down, the machine can switch to another production and resume work.

In addition, a plastic injection machine has several molds per press to produce a large quantity in a very short time. With a pre- series mold, one obtains solid products and good qualities.

What is the importance of mold process?

In plastic injection molding companies near me the method is common to duplicate many identical parts, especially for production with a small series mold. It seems ideal for carrying out precise work and for having objects of all sizes, large or small. However, this process is ecological. Because the raw material can recycle and reuse several times without losing its characteristics.

Returning to the concepts learned in this blog in which we have talked about the cooling of molded parts. Let us remember that plastics remove heat to the point where the part is easy to expel without suffering deformation.

To achieve this objective, we must know and understand the appropriate expulsion temperature. It has to do with the HDT of the plastic common,

WHAT IS HDT OF PLASTICS?

From plastic injection molding companies near me we come to know that The HDT means thermal deflection temperature or thermal distortion temperature. HDT is a value that represents the resistance of a plastic to distortion under a given physical load at an elevated temperature. In other words, it is an indicator of the stiffness of the material as its temperature increases.

WHAT IS THE HDT TEST ON PLASTICS?

Following the regular standards, the HDT test consists of immersing a bar of specific thickness and dimensions molded with the plastic to analyze in oil. The oil temperature increases at a controlled rate, usually 2 ° C per minute. The temperature at which the bar of material deforms 0.25 mm records as its HDT value.

Typically the loads common in the test are (264 psi). However, occasionally higher load tests are performed, for example, 5.0 MPa, it is often useful to predict the maximum service temperature of parts subjected to high mechanical loads.

HOW TO RELATE THE HDT WITH THE MOMENT OF EXPULSION OF THE PIECE?

Plastic injection molding companies near me tells that the HDT helps to indicate how a plastic part will behave under heat and mechanical load. However, it is very useful in the molding process as an indicator of the maximum temperature to eject the part without it suffering deformation is common by the ejection mechanism of the mold.

At the moment of expulsion, the part must be rigid enough not to suffer deformation, in other words, ensure that the plastic is at values below its HDT. If the plastic is above its HDT, it becomes soft and malleable and the release pins can penetrate it or deform the part. However, if it is below its HDT, it becomes rigid making it easier to remove from the mold.

3D printing: the specifics and features of the application of the technology of the future

The method is in demand in all areas of the production of plastic products. The functional printer prints layer-by-layer with polymer common filament, recreating the outlines and shapes of the digital model loaded into the software. The technology appeared for the piece production of parts at the request of inventors, architects, scientists, medical workers, builders.

Benefits:

- Time spent at the preparatory stage reduces to zero - to start production. Moreover, it is enough to send the received 3D model to the printer

- there is no need to purchase additional equipment, auxiliary equipment

- Almost any project is easy to implement - printers work with many types of polymers. Similarly, it ensures identical accuracy and full compliance of workpieces with requirements