In today's fast-paced manufacturing industry, efficiency and speed are crucial factors for success. One innovative solution that has revolutionized the production process is rapid injection molding. ACE Injection Moulding Company, a global leader in the field, offers exceptional services for designing and manufacturing high-quality plastic injection molds and embedded molded parts.

I. Rapid Injection Molding: Revolutionizing the Manufacturing Industry

Current fast-paced manufacturing landscape, where time-to-market is crucial, companies are constantly seeking efficient and cost-effective production methods. One such game-changing solution is rapid injection molding. This innovative process allows for the quick and economical production of high-quality plastic components.

1. Industry Needs: Streamlining Production Processes

To remain competitive, manufacturers across various industries strive to optimize their production processes. Traditional injection molding methods often involve long lead times, high tooling costs, and minimum order quantities, making it challenging to meet the demands of rapidly evolving markets. Rapid injection molding offers a compelling solution by significantly reducing both lead times and tooling costs. This allows companies to accelerate their production timelines while maintaining the desired level of quality.

2. Industry Needs: Ensuring Design Flexibility

Design flexibility is another critical aspect driving the adoption of rapid injection molding. With the ability to quickly produce plastic components, manufacturers can easily modify and refine designs without incurring substantial costs or delays. This flexibility empowers companies to respond swiftly to market feedback, incorporate design improvements, and stay ahead of the competition.

II. Automotive Parts Manufactured with Rapid Injection Molding

ACE Injection Moulding Company specializes in the rapid production of a wide range of automotive parts using their cutting-edge injection molding technology. Some of the automotive parts they excel in manufacturing include seatbacks, deckled trims, inside door handles, door trims, engine parts, roof parts, lighting parts, mudguard parts, airbags, and air conditioner components. By leveraging its expertise and advanced machinery, ACE Injection Moulding Company can deliver high-quality automotive components efficiently and effectively.

III. Advantages of Rapid Injection Molding

Rapid injection molding offers numerous advantages over traditional manufacturing methods. ACE Injection Moulding Company utilizes these advantages to provide its clients with exceptional results.

1. Speed and Efficiency:

The primary advantage of rapid injection molding is the significant reduction in production time. ACE Injection Moulding Company leverages its expertise and state-of-the-art technology to streamline the manufacturing process, allowing for faster production cycles. This accelerated timeline translates into a shorter time-to-market, enabling their clients to bring their products to market swiftly.

2. Cost-Effectiveness:

Rapid injection molding also brings cost-effectiveness to the manufacturing process. By using advanced techniques and tools, ACE Injection Moulding Company minimizes tooling costs associated with traditional mold manufacturing. The streamlined process reduces material waste, enhances resource utilization, and optimizes production efficiency, ultimately resulting in cost savings for their clients.

3. Design Flexibility:

With rapid injection molding, ACE Injection Moulding Company empowers its clients with design flexibility. This technology enables the creation of complex geometries that would otherwise be challenging to achieve using conventional manufacturing methods. Additionally, rapid injection molding allows for iterative prototyping, facilitating design modifications and enhancements as needed, leading to better final products.

IV. Case Study: Success Stories with ACE Injection Moulding Company

ACE Injection Moulding Company has a proven track record of successful projects and satisfied customers. Through their commitment to excellence, they have garnered several testimonials and completed notable projects.

1. Customer Testimonials:

Numerous clients have expressed their satisfaction with ACE Injection Moulding Company's services, highlighting the company's dedication to quality, efficiency, and customer support. These testimonials serve as a testament to the company's commitment to exceeding expectations.

2. Notable Projects:

ACE Injection Moulding Company has undertaken various projects showcasing its expertise in rapid injection molding. Some notable projects include the production of customizable seatback designs that prioritize both comfort and safety. Additionally, the company has demonstrated its capabilities in manufacturing innovative lighting components that enhance the functionality and aesthetics of automotive vehicles.

Ⅴ. ACE Injection Moulding Company: Meeting the Industry's Demands

ACE Injection Moulding Company stands out as a premier manufacturer, committed to delivering exceptional quality and exceeding customer expectations. Their expertise lies in designing and producing plastic injection molds and embedded molded parts. With an unwavering dedication to meeting clients' mold quality standards, ACE Injection Moulding Company provides OEM/ODM services, ensuring the utmost satisfaction for their customers.

1. Introduction to ACE Injection Moulding Company

At the forefront of the rapid injection molding revolution stands ACE Injection Moulding Company. With years of experience and expertise, ACE has established itself as a trusted manufacturer in the industry. The company is renowned for its commitment to quality, reliability, and delivering exceptional results within tight timelines.

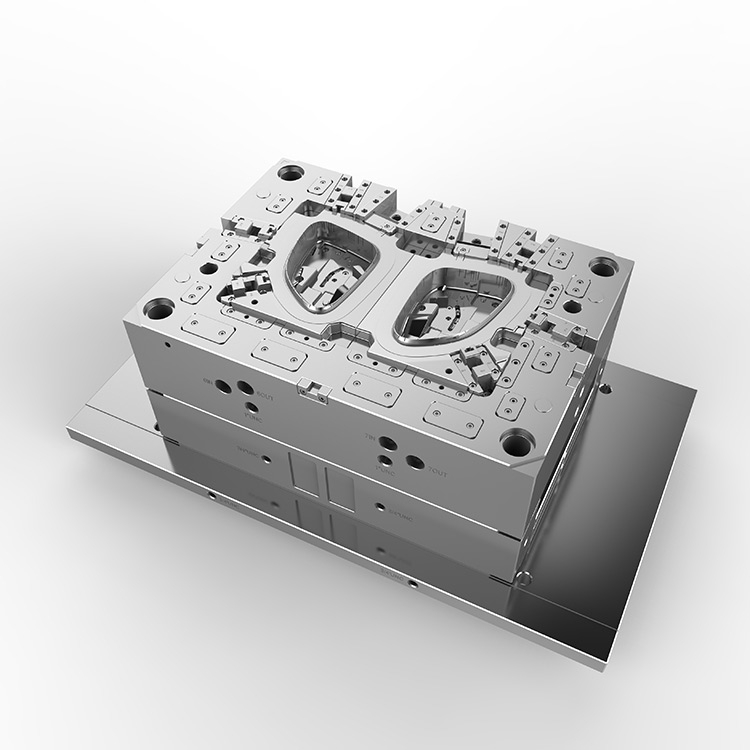

2. Advanced Technology and State-of-the-Art Facilities

ACE Injection Moulding Company harnesses cutting-edge technology and operates state-of-the-art facilities to ensure the highest standards of production. The company's investment in advanced equipment, coupled with its skilled workforce, enables it to deliver superior-quality plastic components at rapid turnaround times.

3. Versatility in Component Manufacturing

ACE Injection Moulding Company offers a wide range of services, catering to diverse industry needs. From seatbacks and deckled trims to engine parts, lighting components, and air conditioner parts, ACE has the expertise to manufacture an extensive variety of plastic components. Its capabilities extend to producing door trims, inside door handles, roof parts, mudguard parts, airbags, and other critical automotive components.

4. Collaborative Approach and Customer Satisfaction

ACE Injection Moulding Company values its customers and takes a collaborative approach to every project. From initial design discussions to final production, ACE works closely with its clients, ensuring their requirements are met, and their expectations are exceeded. By prioritizing customer satisfaction, ACE has earned a reputation for reliability, professionalism, and delivering exceptional results.

Conclusion

Rapid injection molding has emerged as a game-changing manufacturing solution, enabling companies to accelerate their production processes while maintaining high-quality standards. ACE Injection Moulding Company stands at the forefront of this innovative technology, offering its expertise in designing and manufacturing a wide range of automotive parts. With their commitment to excellence, ACE Injection Moulding Company ensures speed, cost-effectiveness, and design flexibility for their clients. By partnering with ACE Injection Moulding Company, manufacturers can unlock the full potential of rapid injection molding and stay ahead in today's competitive market.