How Can Prototyping Metal Parts Benefit Your Industry?

To stay competitive in today’s rapidly evolving industrial landscape, it’s important to constantly innovate and adapt. One area of innovation that has seen significant advancements is prototyping metal parts, and it’s a game changer for many industries. ACE is at the forefront of this revolution. In this blog post, we will explore how prototyping metal

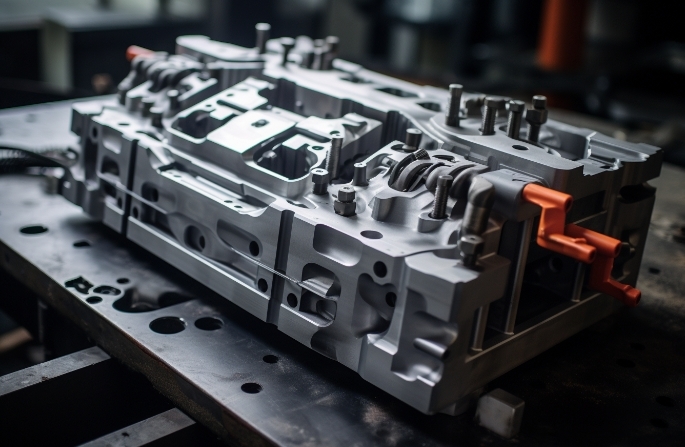

What Lies Ahead for Plastic Moulding Dies in the 21st Century?

Plastic moulding dies are a crucial tool for shaping and producing a wide range of plastic products. As we step into the 21st century, the role and significance of plastic moulding dies are expected to continue growing. In this blog, we will explore how it can be used to create perfectly shaped products and assess

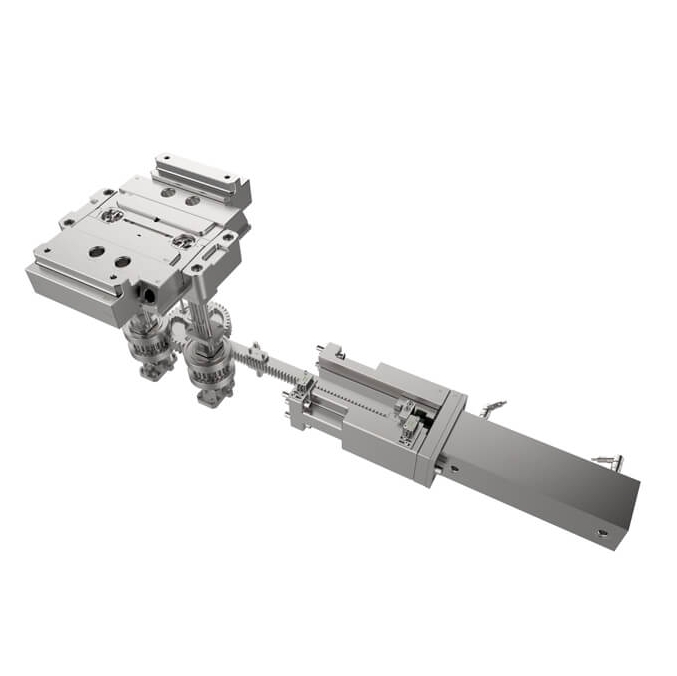

Can High Speed Mold Help You Meet Tight Deadlines and Demands?

For manufacturers, efficiency and precision are crucial in meeting tight deadlines and satisfying customer demands. One technology that has gained prominence in recent years is High Speed Molding, which offers remarkable advantages in terms of speed and customization. We will explore the potential of High Speed Mold and its role in manufacturing customization, the impact

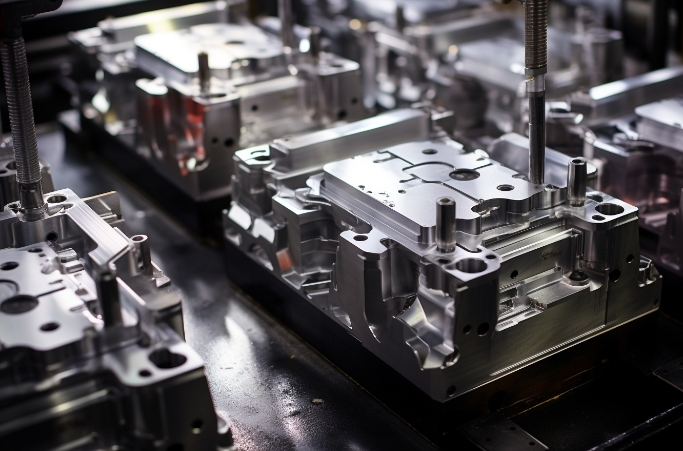

Are Molding Companies the Cornerstone of Product Development?

In the world of manufacturing and product development, molding companies play a crucial role. These companies are often the unsung heroes behind many of the products we use daily, from automotive parts and consumer electronics to medical devices and packaging materials. One such prominent player in the molding industry is ACE Molding. In this blog,