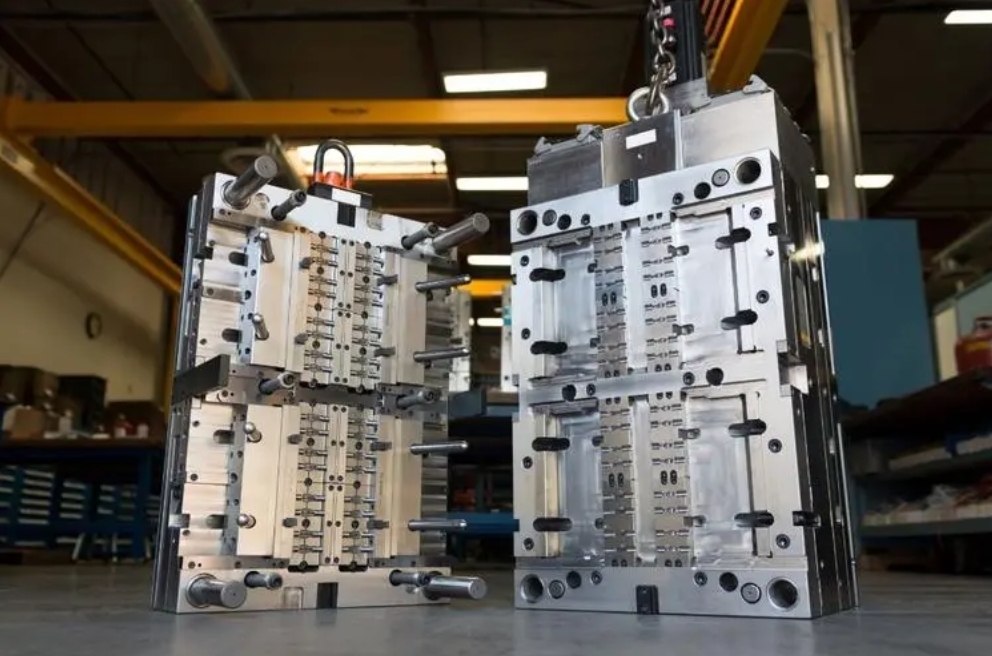

When it comes to plastic die mould manufacturing, quality assurance is of paramount importance. The right plastic die mould can make or break a production process, affecting product quality, efficiency, and cost-effectiveness. This article will explore the key factors to consider when choosing a plastic die mould manufacturer, with a focus on ACE, a leading player in the industry.

Selecting the Right Plastic Die Mould Manufacturer

Selecting the right plastic die mould manufacturer is a crucial decision for any business involved in plastics manufacturing. Quality assurance begins with the manufacturer's reputation. ACE, for instance, has established itself as a trusted name in the industry, known for its commitment to delivering top-notch plastic die moulds. Here are some essential aspects to consider when evaluating a manufacturer:

1. Expertise and Experience: A manufacturer's experience in plastic die mould manufacturing is a fundamental criterion. ACE, with its years of experience, brings a wealth of knowledge and expertise to the table. Their experienced team can provide valuable insights and guidance throughout the entire manufacturing process.

2. Quality Control Measures: A manufacturer's commitment to quality is evident in their quality control measures. ACE has a robust quality control system in place to ensure that every plastic die mould they produce meets the highest standards. This includes rigorous inspection and testing protocols.

3. Customization Capabilities: Plastic die mould requirements can vary significantly from one project to another. A reputable manufacturer should offer customization options to meet the specific needs of their clients. ACE excels in offering customized solutions, allowing clients to design and develop moulds tailored to their unique requirements.

Streamlining Production with the Right Plastic Die Mould Manufacturer

Efficiency and productivity are key goals for any business. Choosing the right plastic die mould manufacturer can help streamline your production processes and reduce downtime. ACE offers a range of benefits to help you achieve these goals:

1. High-Quality Materials: ACE uses top-quality materials to manufacture plastic die moulds. The use of high-quality materials ensures the longevity and durability of the moulds, reducing the need for frequent replacements and maintenance.

2. Precision and Accuracy: ACE's commitment to precision and accuracy in manufacturing ensures that the moulds are dimensionally stable, resulting in consistent and high-quality production. This precision helps in reducing rejects and wastage.

3. Timely Delivery: Delays in receiving plastic die moulds can lead to production bottlenecks. ACE understands the importance of timely delivery and strives to meet the deadlines to keep production on schedule.

How to Design the Perfect Plastic Die Mould Products with Your Plastic Die Mould Manufacturer

Collaboration between the client and the plastic die mould manufacturer is essential in designing the perfect mould products. ACE fosters a collaborative approach to ensure the clients' needs and specifications are met:

1. Consultation and Design Phase: The process begins with a consultation, where clients can discuss their project requirements, budget constraints, and any unique design considerations. ACE's experienced team works closely with clients to create an initial design concept.

2. Prototyping and Testing: After the design phase, ACE produces prototypes for testing and evaluation. This allows clients to see the design in action, make adjustments, and ensure that the mould meets their expectations.

3. Refinement and Finalization: Based on the feedback from the prototype testing, ACE refines the design to address any issues or improvements identified. The final design is then produced, meeting the client's expectations.

Exploring the Different Types of Plastic Die Moulds Offered by Manufacturer

Plastic die mould manufacturer like ACE offers a wide range of mould types to suit diverse industry needs. Understanding the different types can help you make an informed choice for your specific applications:

1. Injection Moulds: Injection moulds are the most common type used in the industry. They are used for creating a variety of plastic products, from toys to automotive components.

2. Blow Moulds: Blow moulds are primarily used for creating hollow plastic products, such as bottles and containers.

3. Compression Moulds: Compression moulds are suitable for producing larger, thicker-walled parts. They are commonly used in industries like aerospace and automotive.

4. Extrusion Moulds: Extrusion moulds are used in the production of continuous lengths of plastic profiles, tubing, and pipes. They are widely used in the construction industry.

5. Transfer Moulds: Transfer moulds are used in situations where multiple cavities need to be filled simultaneously, making them ideal for high-volume production.

ACE is known for offering a wide variety of plastic die moulds, ensuring that clients can find the right mould for their specific applications. Whether you need precision injection moulds or specialized compression moulds, ACE has the expertise to meet your requirements.

Cost-Saving Strategies When Working with a Plastic Die Mould Manufacturer

While quality assurance is crucial, cost-saving strategies are equally important when working with a plastic die mould manufacturer. Balancing cost-effectiveness with high-quality mould production can significantly impact your bottom line. Let's explore some strategies to consider when partnering with ACE to achieve cost savings without compromising on quality.

1. Design Optimization: Best Plastic Die Mould Manufacturer

One effective way to save costs is to optimize the design of your plastic parts and moulds. ACE offers design consulting services that can help you identify areas where design improvements can lead to reduced material usage and shorter production cycles. By working closely with their team, you can achieve significant cost savings without sacrificing quality.

2. Material Selection: Best Plastic Die Mould Manufacturer

Choosing the right materials is critical in plastic die mould manufacturing. ACE can guide you in selecting cost-effective materials that still meet your product's specifications. They have extensive knowledge of various materials and can help you make informed decisions to minimize material costs.

3. Efficient Production Processes: Best Plastic Die Mould Manufacturer

ACE utilizes efficient production processes that reduce lead times and waste. They leverage automation and the latest manufacturing techniques to optimize production and minimize costs. By streamlining production, you can save both time and money, making ACE a cost-effective choice.

4. Volume Discounts: Best Plastic Die Mould Manufacturer

When working with a reputable manufacturer like ACE, you can benefit from volume discounts. Ordering in larger quantities can result in lower per-unit costs. ACE can assist you in optimizing order quantities to achieve the most significant cost savings while ensuring that your production needs are met.

5. Customization for Cost Savings: Best Plastic Die Mould Manufacturer

ACE offers customized solutions to meet your specific requirements. This means you don't have to pay for features or specifications that are unnecessary for your project. By tailoring the mould production to your exact needs, you can avoid unnecessary expenses.

Conclusion

The choice of a plastic die mould manufacturer plays a significant role in the success of your plastic manufacturing processes. ACE, with its extensive experience, commitment to quality, and customization capabilities, stands out as a reliable partner for businesses in need of plastic die moulds.

Collaborating with a trusted manufacturer like ACE can help streamline production, reduce downtime, and ensure that the perfect moulds are designed for your specific needs. Understanding the different types of plastic die moulds offered by manufacturers allows you to make an informed choice based on your industry and product requirements. With ACE's expertise and dedication to quality, you can look forward to a successful partnership in plastic die mould manufacturing.