For companies who want to produce high-quality plastic components and products, custom injection molding has become a go-to solution. Whether you're in the automotive, medical, electronics, or consumer goods industry, custom injection molding offers a versatile and cost-effective means of manufacturing.

This blog will provide you with a comprehensive guide to custom injection molding, covering key considerations, cost-effective production, its role in the future of manufacturing, and real-world case studies of its applications. We'll also introduce you to ACE, a trusted custom injection molding manufacturer.

Custom Injection Molding: Key Considerations for Cost-Effective Production

Custom injection molding involves the process of creating plastic components by injecting molten material into a mold cavity. The process is highly versatile and adaptable, making it ideal for a wide range of industries. To ensure cost-effective production, several key considerations must be taken into account:

1. Design for Manufacturability: The design of your product or component plays a crucial role in determining production costs. Working closely with your custom injection molding manufacturer like ACE can help optimize your design for manufacturing, reducing material waste and cycle times.

2. Material Selection: Choosing the right material is essential for achieving cost-effectiveness. The choice of material impacts not only the quality and performance of the final product but also its production cost. ACE can help you select the most suitable material for your specific application.

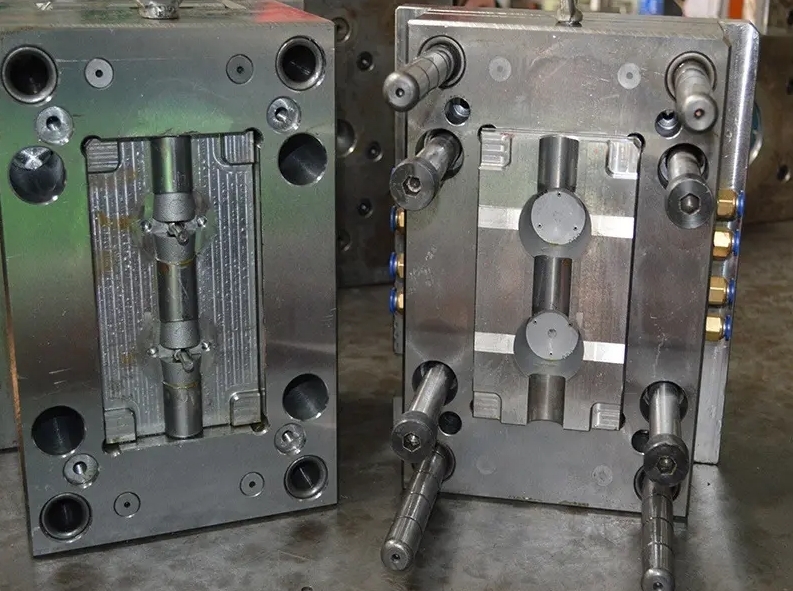

3. Tooling and Mold Design: Proper tooling and mold design can significantly affect production costs. Investing in high-quality molds and maintaining them regularly can lead to long-term cost savings. ACE specializes in creating precise molds for custom injection molding.

4. Production Volume: Consider your required production volume when planning your custom injection molding project. Higher volumes can lead to cost savings through economies of scale, but small to medium runs are also feasible with custom injection molding.

5. Quality Control: Quality assurance is critical in custom injection molding to avoid defects and rework, which can drive up costs. ACE follows stringent quality control measures to ensure consistently high-quality products.

Why Custom Injection Molding is the Future of Production

Custom injection molding is on the rise and for several good reasons. As the manufacturing landscape evolves, this process is becoming increasingly relevant and integral to the future of production. Here's why:

1. Efficiency and Precision: Custom injection molding offers high precision and repeatability, resulting in products with consistent quality. The process is efficient, with short cycle times, allowing for high-volume production.

2. Material Variety: A wide range of materials, including thermoplastics and thermosetting plastics, can be used in custom injection molding. This versatility enables manufacturers to produce components for diverse industries.

3. Sustainability: Many modern custom injection molding processes are designed with sustainability in mind. Minimizing material waste and energy consumption, it contributes to eco-friendly manufacturing.

4. Customization: Custom injection molding allows for intricate and complex shapes and features. Manufacturers can tailor their products to meet specific design and functionality requirements.

5. Cost-Effectiveness: As discussed earlier, cost-effective production is achievable through careful planning, design optimization, and material selection.

Case Studies: Real-World Applications of Custom Injection Molding

To understand the practical applications of custom injection molding, let's explore a few real-world case studies:

1. Automotive Industry: Custom injection molding is widely used in the automotive sector to produce various components such as interior trim parts, exterior body panels, and under-the-hood components. These parts require high precision, durability, and resistance to temperature and chemicals.

2. Medical Devices: Custom injection molding plays a crucial role in manufacturing medical devices, including syringes, IV components, and diagnostic equipment. The process ensures that these products meet stringent quality and safety standards.

3. Consumer Electronics: The consumer electronics industry relies on custom injection molding to produce casings, buttons, and connectors. This method allows for intricate designs and precise dimensions while ensuring durability.

4. Toys and Games: The toy and game industry utilizes custom injection molding to create a wide range of products, from action figures to board game pieces. The process ensures that these items are safe, durable, and aesthetically appealing.

Choosing the Right Custom Injection Molding Partner

When seeking a custom injection molding partner, buyers should consider several factors:

1. Experience and Expertise

Look for a manufacturer with a track record of producing high-quality components in your industry. ACE, with its decades of experience, has a strong reputation for delivering precision-molded parts to diverse sectors.

2. Technological Capabilities

Ensure the manufacturer uses the latest technology and equipment for injection molding. ACE employs cutting-edge machinery to guarantee efficient and precise production.

3. Quality Assurance

A reliable custom injection molding partner, like ACE, should have a robust quality control system in place to maintain the highest standards throughout the production process.

4. Material Options

Choose a manufacturer with a broad selection of materials to meet your part's specific requirements. ACE offers a wide range of thermoplastic materials to suit diverse applications.

5. Flexibility and Customization: Custom Injection Molding

Custom injection molding is all about meeting your unique needs. Look for a manufacturer that can adapt to your project's specific demands and provide tailor-made solutions.

ACE: Your Trusted Custom Injection Molding Partner

ACE is a leading custom injection molding manufacturer, trusted by clients across various industries. With a strong commitment to quality, precision, and client satisfaction, ACE has a proven track record of delivering exceptional plastic components.

As a forward-thinking company, ACE invests in cutting-edge technology, ensuring that its manufacturing processes remain at the forefront of the industry. From prototyping to production, ACE stands out as a versatile and reliable partner for your custom injection molding needs.

Conclusion

Custom injection molding is a versatile and cost-effective production method that plays a vital role in various industries. By focusing on design, material selection, tooling, and quality control, manufacturers can achieve efficient and sustainable production. As we move forward in the world of manufacturing, custom injection molding is poised to play an even more significant role, offering efficiency, customization, and sustainability to meet the demands of modern industries.

For your custom injection molding needs, consider partnering with ACE, a trusted manufacturer dedicated to producing top-quality components and products.