A Comprehensive Guide to Plastic for Injection Molding: Unlocking the Possibilities!

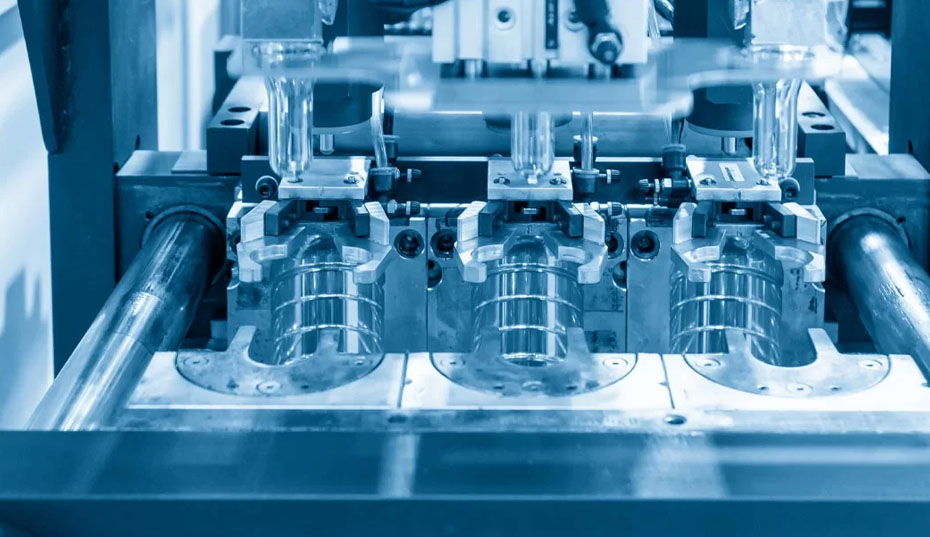

Injection molding is a manufacturing process in which plastic is melted and injected into a mold, where it cools and solidifies into the final product. There are many types of plastics that can be used in injection molding, including polyethylene, polypropylene, polystyrene, ABS, and nylon. The choice of plastic will depend on the desired properties

Secrets to Achieving Top-Notch Plastic Injection Molding Quality Engineering!

Plastic injection molding quality engineering is the field of engineering that focuses on ensuring the quality of parts produced using the plastic injection molding process. It involves the use of various techniques and tools to optimize the molding process and identify and correct any issues that may arise. Some examples of quality engineering in plastic

The Benefits of Plastic Runner Injection Molding

Plastic runner injection molding is a cost-effective solution for creating products with complex designs. It can be used to produce plastic parts with intricate details, allowing for a high degree of precision. Its versatility makes it suitable for a wide range of applications, including medical and automotive components. In plastic injection molding, the plastic material

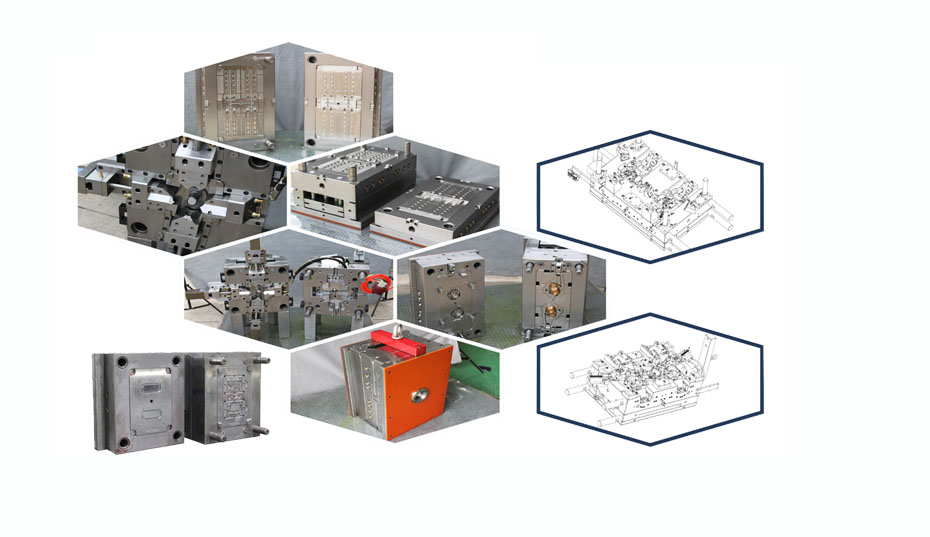

The Benefits of Precision Injection Moulding

Precision injection molding is a manufacturing process in which melted plastic is injected into a precision-machined mold under high pressure. The plastic cools and solidifies in the mold, taking on the shape of the mold cavity. The resulting parts are very precise and have tight tolerances. This process is commonly used for producing small, intricate