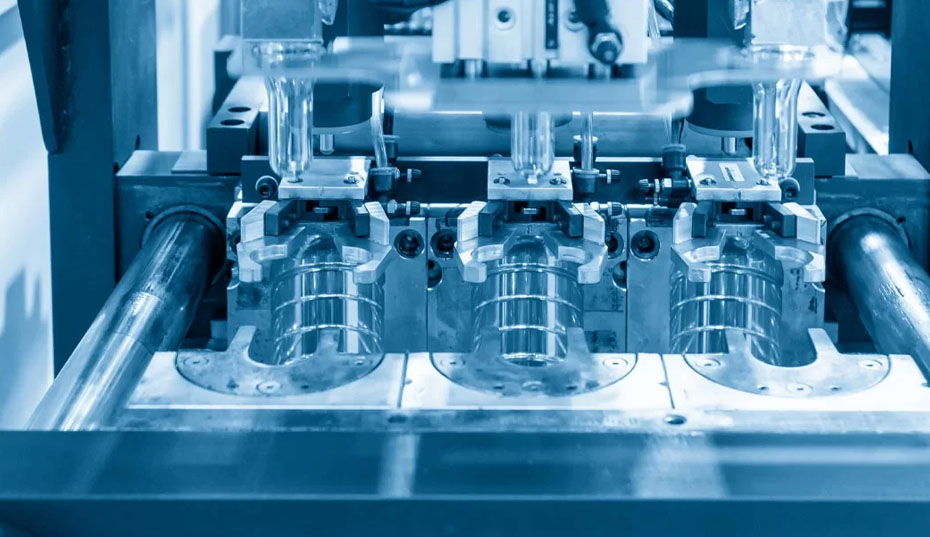

Plastic injection molding quality engineering is the field of engineering that focuses on ensuring the quality of parts produced using the plastic injection molding process. It involves the use of various techniques and tools to optimize the molding process and identify and correct any issues that may arise.

Some examples of quality engineering in plastic injection molding include: -Designing and developing robust and efficient molds -Monitoring and controlling process variables such as temperature, pressure, and flow rate -Using statistical process control (SPC) and other data analysis techniques to identify and correct variations in the molding process -Performing testing and inspection on parts to ensure they meet specifications -Design of Experiments (DoE) to improve the process and reduce variations -Continuous improvement activities like Kaizen, FMEA and Root cause analysis

Quality engineering in plastic injection molding is an important aspect of the manufacturing process, as it helps ensure that parts are consistent, reliable, and meet customer specifications.

Plastic injection molding is a complex process that requires precise engineering and quality control to ensure the highest quality product. Quality engineering is the practice of ensuring that the plastic injection molding process is efficient, accurate, and cost effective. It requires the use of advanced tools, techniques and processes to ensure the highest quality product is produced. In this blog, we will discuss what plastic injection molding quality engineering is, the benefits of it, the challenges in achieving top-notch quality engineering, the secrets to achieving top-notch plastic injection molding quality engineering, best practices for implementing plastic injection molding quality engineering, plastic injection molding quality engineering tools, common pitfalls and how to avoid them, tips and tricks for achieving top-notch plastic injection molding quality engineering, and courses for plastic injection molding quality engineering.

What is Plastic Injection Molding Quality Engineering?

Plastic injection molding quality engineering (PIMQE) is the practice of ensuring that the plastic injection molding process is efficient, accurate, and cost effective. It requires the use of advanced tools, techniques and processes to ensure the highest quality product is produced. Quality engineering is essential to ensure the plastic parts produced have the right size, shape, and durability, and also meet the customer’s specifications.

The quality engineering process starts with the design process, which involves creating 3D models of the plastic parts to be produced, as well as the injection molds that will be used. The 3D models are then analyzed using specialized computer-aided engineering (CAE) software to ensure that they are accurate and will produce the desired outcome. Once the 3D models and injection molds have been created and analyzed, they are used to create the actual plastic parts. During this process, specialized quality engineering tools and techniques are used to ensure that the plastic parts are produced to the highest standard.

Benefits of Plastic Injection Molding Quality Engineering

Plastic injection molding quality engineering is essential for producing high quality plastic parts that meet the customer’s specifications. Quality engineering also helps to reduce costs, as parts that are produced correctly will require fewer resources to be produced. Additionally, quality engineering helps to improve the efficiency of the plastic injection molding process, as fewer resources are wasted on producing parts that are not up to standard. Quality engineering also ensures the longevity of the plastic parts, as they are produced to last for a long time without any defects.

Challenges in Achieving Top-Notch Quality Engineering

The biggest challenge in achieving top-notch quality engineering is ensuring that the 3D models and injection molds are accurate and will produce the desired outcome. This is a complex and time-consuming process that requires specialized knowledge and experience to get right. Additionally, the plastic injection molding process is complex and requires a great deal of skill and experience to ensure that parts are produced to the highest standard.

The Secrets to Achieving Top-Notch Plastic Injection Molding Quality Engineering

The key to achieving top-notch plastic injection molding quality engineering is to ensure that the 3D models and injection molds are accurate and will produce the desired outcome. This requires the use of advanced computer-aided engineering software, as well as experienced engineers who understand the complex plastic injection molding process. Additionally, it is important to have a rigorous quality control process in place to ensure that the parts are being produced to the highest standard.

Best Practices for Implementing Plastic Injection Molding Quality Engineering

In order to achieve top-notch plastic injection molding quality engineering, it is important to follow best practices. This includes using advanced computer-aided engineering software to ensure that the 3D models and injection molds are accurate, as well as experienced engineers who understand the process. Additionally, it is important to have a rigorous quality control process in place to ensure that the parts are being produced to the highest standard. Additionally, it is important to have a continuous improvement process in place to ensure that any issues are quickly identified and rectified.

Plastic Injection Molding Quality Engineering Tools

There are a number of tools available to help with plastic injection molding quality engineering. These tools include computer-aided engineering software, as well as specialized quality engineering tools such as dimensional inspection tools, process capability analysis tools, and process control tools. These tools help to ensure that the 3D models and injection molds are accurate, and that the plastic parts are produced to the highest standard.

Common Pitfalls and How to Avoid Them

One of the most common pitfalls in plastic injection molding quality engineering is not having a rigorous quality control process in place. It is essential to have a quality control process in place to ensure that the parts are being produced to the highest standard. Additionally, it is important to have a continuous improvement process in place to ensure that any issues are quickly identified and rectified.

Tips and Tricks for Achieving Top-Notch Plastic Injection Molding Quality Engineering

There are a number of tips and tricks that can be used to help achieve top-notch plastic injection molding quality engineering. It is important to use advanced computer-aided engineering software to ensure that the 3D models and injection molds are accurate. Additionally, it is important to have experienced engineers who understand the complex plastic injection molding process. It is also important to have a rigorous quality control process in place to ensure that the parts are being produced to the highest standard. Additionally, it is important to have a continuous improvement process in place to ensure that any issues are quickly identified and rectified.

Courses for Plastic Injection Molding Quality Engineering

There are a number of courses available to help those interested in plastic injection molding quality engineering. These courses provide an in-depth understanding of the plastic injection molding process, as well as the advanced tools, techniques, and processes needed to ensure that the parts are produced to the highest standard. Additionally, these courses provide hands-on experience with the tools and processes involved, giving students the knowledge and confidence to ensure the highest quality product is produced.

Conclusion

Plastic injection molding quality engineering is essential for producing high quality plastic parts that meet the customer’s specifications. Quality engineering also helps to reduce costs, as parts that are produced correctly will require fewer resources to be produced. Additionally, quality engineering helps to improve the efficiency of the plastic injection molding process, as fewer resources are wasted on producing parts that are not up to standard. Quality engineering is a complex and time-consuming process that requires specialized knowledge and experience to get right. But, with the right tools, techniques, and processes, it is possible to achieve top-notch plastic injection molding quality engineering.