Plastic molding in china is one of the most efficient and widely common plastic injection molding methods.

The main principle of plastic injection molding is the transformation of the plastic to a viscous consistency that allows it to easily fill the desired shape and flow through the channels of the injection equipment.

How we can fill shapes in plastic molding in china?

Filling of a predetermined shape occurs by injection or conventional movement of the molten hot mass of plastic, where it assumes a certain configuration and becomes solid. For the manufacture of different types of products, different types of plastics, casting modes and shapes are common, which are adjustable and easy to change. That allows you to get the desired products.

With the help of injection molding of plastics, a wide variety of products are easy to produce, the mass of which can range from a few tenths of a gram to several kilograms. Modern injection molding technologies make it possible to produce products from plastics of a wide variety of thicknesses, which, as a rule, are 3-6 mm.

What is the required pressure level for plastic molding in china?

The plastic molding in china process takes place under different pressure levels, most often the parts manufacture at 45xUdHPiFHQ7xbKh19G45saF1raB2ot5pag8p1Hnk4yrfXRJZskr8TMbFpVfC5tDk8eQQg63TqkW9gKhwagx6HePTaK2yXbstrength characteristics.

Also, ultra-high pressure contributes to the most accurate transfer of the dimensions of the product parts. The choice of the required pressure level depends on the following factors: the degree of viscosity and melt ability of the plastic, the mold, the desired result, and others. The molds are exactly the same as the product you want to receive.

Why mold is important?

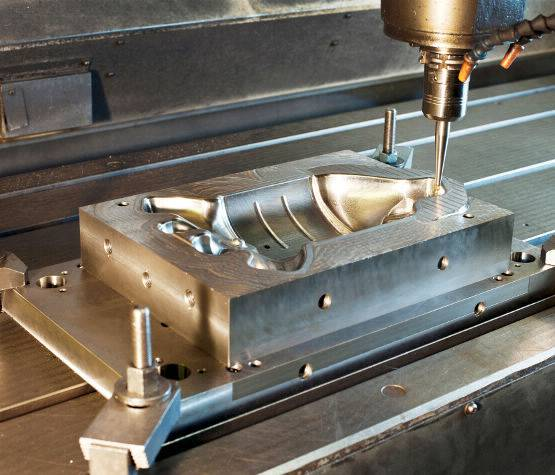

Obtaining a product by plastic molding in china of plastics is impossible without the use of a mold. The mold production process is quite long, complicated and expensive. This is due to the uniqueness of each individual mold, high quality surface treatment in the form and repetition of the complex geometry of the manufactured product.

How the cost of a mold is formed?

There are several types of plastic injection molding, each of them has certain advantages and is common to improve the quality of a particular product. Injection molding makes it possible to obtain products with minimally thin walls or, conversely, with very thick walls. Injection molded products have less shrinkage.

The main difference with injection molding is that molten plastic is injected into a mold that is not completely closed. Intrusion, a type of plastic injection, is common in the manufacture of plastic molding in china with thick walls; the principle of this method is to inject less material into the mold than is required.

How high quality products are obtained?

The use of a variety of technologies in the molding of plastic products allows you to obtain a high-quality and desired result. Moreover, molding of plastic products of any shape and color

We will make according to drawings, sketches, according to a sample. According to your ideas!

We will do “the same” or help to change by offering our non-standard solutions: “What is better, simpler and cheaper”.

Moreover, we will be able to develop something that does not exist yet and has never been done.

Similarly, we will develop CD, 3D models.

Let's print a prototype.

Furthermore, we will make the tooling ourselves: a mold for plastic injection

In addition, minimum terms.

Injection plastic molding in china

A thermoplastic machine (TPA) heats the polymer to a liquid state and injects it into a metal tool - a mold. Plastic molding in china consists of two leaves, which close together, creating a tremendous effort. This is how the casting forms. After the polymer has solidified, the tool opens; the finished part moves out. Similarly, then the cycle repeats, starting multiple casting of products.

Why plastic injection mold is common?

Plastic injection molding is performed with great precision. Tolerances are less than hundredths of a millimeter. This technology creates elements of such complexity and configuration that are unattainable by other methods.

Furthermore, the productivity of the process is very high. Having ready-made tooling, in a couple of days they receive batches of 100,000 pieces or more.

The process common in quality plastic molding in china:

The starting material is raw plastic particles with high moisture content. This will dry at a suitable temperature. Depending on the desired product color, it mixes with different types of pigments and colorants.

Raw plastic granules in plastic molding in china. From there, the injection molding machine performs the transportation of the plastic towards the plastic injection mold.

The raw plastic pellets in the press box will heat at a suitable temperature. Furthermore, the molten plastic stream will maintain in a liquid state, not solidified.

The molten plastic stream under the effect of pressure will inject into the mold cavity.

What determines the cost of injection molding of plastics?

Plastic molding in china is the most economical method of mass production, but it is important to correctly calculate the parameters of the working matrix. To increase productivity, they design not one, but several working nests at once, design an automatic ejection.

The cost of injection molding of plastics depends on two factors. Similarly, the manufacturability of the mold and the circulation will impact the results. If the mold has not one, but four, eight or more working cavities, then for one closing, a series of cast elements immediately obtain.

Custom injection molding

Plastic molding in china is an efficient and highly productive way of producing products. Thus, tens and hundreds of thousands of streaming products appear. Moreover, this is optimal in terms of financial and time costs.

Advantages of injection molding

The ability to process different types of plastic.

Moreover, full automation of the plastic injection molding process.

The ability to manufacture parts of complex shapes with high accuracy.

Furthermore, it is not always possible with the use of other technologies for processing plastics.

In addition, products created by this method are easy to reinforce, hybrid or hollow.