The most economical prototype tooling China

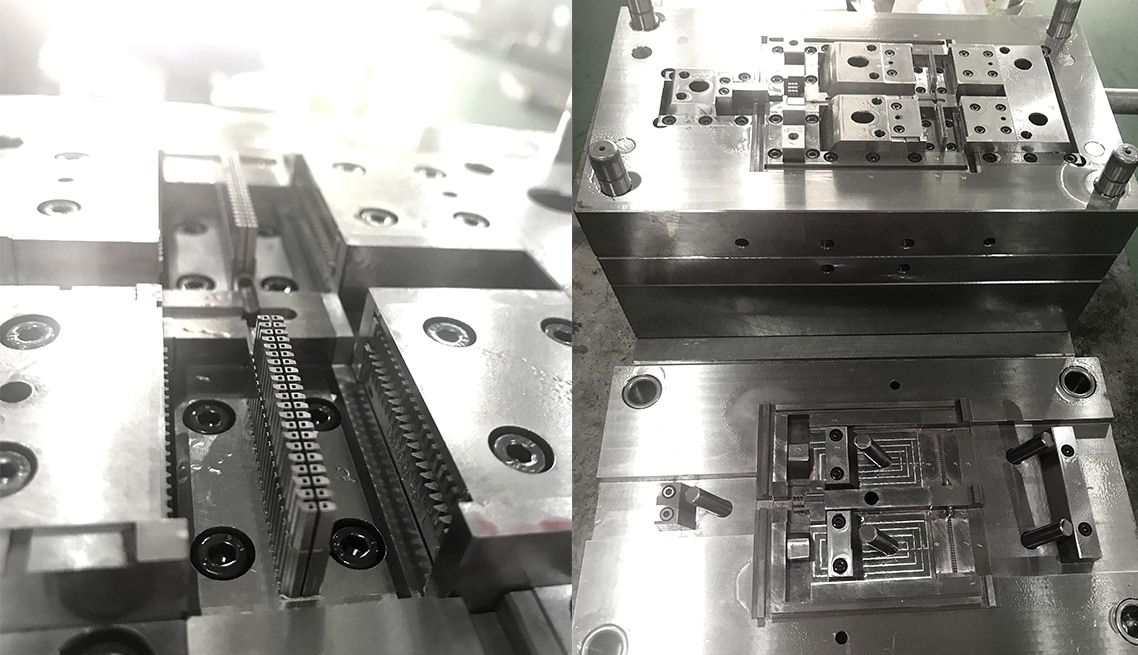

To get a plastic prototype with the right design as required, it is necessary to precisely process the plastic injection mold and prototype tooling China. The cost of making plastic injection molds is always a matter of careful consideration when investing.

The price of making prototype tooling China is affected by many factors

The price of plastic injection mold making is influenced by many factors, which can be direct or indirect effects, which include:

Requirements for plastic prototypes

The quality of the prototype your company needs to produce, the size and shape of the prototype is one of the factors that determine the price of the prototype. Prototypes with large dimensions, high requirements for aesthetics, precision and complexity will incur high mold prices.

Plastic injection mold quality

The price of prototype tooling China is affected by many factors, which are decided based on the prototype quality desired by the customer, the quality of the plastic injection mold that the customer has set.

The mold material, the complexity of the mold structure, the smoothness of the mold surface after machining and the necessary mold components all affect the price of the plastic injection mold. Plastic injection molds with different quality will have different requirements in terms of expertise and processing time.

Method to optimize mold cost?

Saving input costs is an important premise to be profitable when manufacturing plastic prototypes, thereby optimizing the cost of making plastic injection molds. In other words, it is necessary to find a method to produce plastic injection molds that meet quality standards at the lowest cost.

To optimize the cost of mold making and prototype tooling China, businesses need to come up with specific methods and implement:

- Prototype design needs to be optimized.

- Thoroughly optimize the plastic injection mold design.

- Choose the most suitable plastic injection mold material and use it.

What is the importance of optimizing?

Optimizing prototype design is really necessary, an important basis from which to optimize injection mold design, this is considered one of the most effective methods to reduce the cost of making plastic molds, reducing costs.

Plastic injection is a process that turns raw materials (plastic beads, recycled plastic and additives) into custom plastic prototypes. Plastic injection mold not only helps to shape the prototype. Moreover, this also ensures that the prototype is easy to remove from the mold easily and optimally.

Why take the prototype out of the mold?

After the mold opens, the prototype will stick on the prototype tooling China again due to the vacuum force and shrinkage of the plastic. Usually the prototype will be restrained to stick on the movable part for convenient removal of the prototype.

However, some prototypes will be stuck on the fixed mold but very rarely. The prototype must be taken out of the mold to make room in the mold cavity before the next injection molding cycle can work properly. Each prototype has its own advantages and disadvantages. So depending on the mold structure, prototype shape and technical requirements, which method is reasonable?

Methods of getting prototypes

Ø Take it by hand

This method uses human labor to remove the prototype from the mold. When the mold opens, the operator will open the machine's protective door. And then use his hands or specialized tools to take the prototype out.

This method is rarely common for small and medium-sized prototypes because it does not bring high economic efficiency. However, for large prototypes where we cannot apply any other prototype extraction methods, this method is a mandatory choice. Prototype tooling China has great importance in this regard.

Ø Take/push the prototype with the pusher

This is the most common prototype taking method that most plastic injection molds use. Basically, this method arranges with one or more pusher systems.

It is to push the prototype out of the mold cavity. This system consists of battery clamp plate, backing plate, return spring, guide pin. The battery method makes the process of removing the prototype from the mold easy and automatic to limit human labor.

Components for assembling the push-pull system are also common. They are easy to find and reasonably priced. However, when the system is arranged, the overall length of the mold will increase, increasing the weight of the mold. And the prototype will leave a pin mark on the prototype, causing unsightly and in the long run.

Ø Take the prototype by pushing the plate

Prototypes with thin cylindrical or rectangular walls are not safe to use. Therefore, people use the method of pushing the plate to remove the prototype from the prototype tooling China. The principle of this method is that the whole mold plate will move out to apply uniform pressure. It comes on the prototype wall in the direction of pushing the prototype out of the mold cavity.

Ø Advantages of this method

The advantage of this method is that the prototype achieves high aesthetics because it does not leave any traces of push. However, the manufacturing of plate push mold requires high precision. The steel material must meet the standards to ensure the durability of the mold.

Ø Take the prototype by steam

This is a method that uses compressed air to push the prototype out of the mold cavity through a tool called "Corn Soup". This method is not common because not all prototypes are easy to apply. Normally, prototypes with a fairly tight and wide pushing surface such as brass, bucket, fork... then people will use this method to get the prototype.

Ø Advantage and disadvantage of this method

The advantage of taking prototypes by gas is that the prototype tooling China is quite simple and compact compared to the arrangement of the tire system. The disadvantage of this prototype is that it is not easy to apply to small prototypes or prototypes with a lot of open surface. Note, when using the method of taking prototypes by gas, it is imperative that your factory has an air tank.

Ø Take prototypes by robot

If you have the conditions and want to automate production, you should install robotic arms. In fact, most prototypes have to rely on the tying system. It is to push the prototype out a certain distance before being picked up by the robot. Some prototypes are easy to pick up directly but must ensure the prototype is not too tight on the mold.

The advantage of picking prototypes by robot is the high automation process, reducing labor costs. This method also has the disadvantage that the initial cost is high. The operator's technical level must also be highly specialized.