Injection plastic mould 2022 Introduction

Plastic products are always very popular thanks to their convenience and toughness. In addition, plastic products are always more colorful than other materials. All of these beloved plastic products are made using injection plastic mould 2022.

What is injection plastic mould 2022?

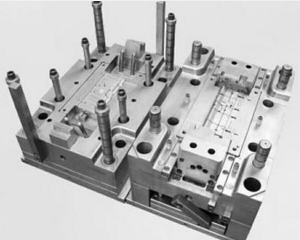

To learn more about plastic injection mold, first, you need to understand the concept of this device. A plastic injection mold is a tool to shape and shape plastic products. A plastic injection mold consists of many parts assembled together.

Here the plastic is injected into the mold and then cooled, then ejected the product. So a plastic product was born! Therefore, plastic injection mold is an important and indispensable part of the production cycle of plastic utensils.

Not only plays a role in creating products, but plastic injection molds also ensure that all products have the same structure and size. Therefore, the size of the injection plastic mould 2022 and the desired size of the product will be the same.

How to choose injection plastic mould 2022?

There are many different types of plastic injection molds on the market. You can base on the size as well as the number of products you want to choose the right plastic injection mold for your needs.

For example, if you only produce a small number of products, choose a 2-plate mold, instead of using a multi-cavity mold or other high-end construction.

Plastic injection mold construction

Injection plastic mould 2022 is divided into two main parts:

Fixed part (Female mold): True to its name, this is the fixed part in the injection molding process. This part has a fixed position to the wall of the plastic injection machine. Further, it has a connection to the plastic injection system of the machine.

The purpose is to carry out the injection of molten plastic material into the mold cavity through the nozzle and channel system.

The movable part (Male mold): There is a reverse part; the movable part has the function of closing the mold to press the product and opening the mold to take the product. In other words, this movable part can be “portable” – that is, it can be opened and closed flexibly.

The movable part is attached to the wall of the injection molding machine. It helps push the product out through a push pin system designed in the injection plastic mould 2022.

Main components and functions of injection plastic mould 2022

Upper clamp plate: Used to fix the upper mold plate and the upper clamp plate into one block, avoiding shifting during operation.

Upper mold plate: This is an important component in plastic injection mold. It is the outer image of the product. At the same time, the upper mold plate will also determine the accuracy of the mold.

This will accurately shape the product. The surface quality of the product will depend entirely on the machining of this mold plate.

Positioner: The locator includes the locating pin and the locating silver. This part has the shape of a circle that protrudes above the top of the front clamp plate, allowing the user to insert a corresponding hole in the side of the machine.

Support plate: Anchor keeps the injection plastic mould 2022 piece from falling out. At the same time, it also helps to support the movable plate and create the necessary clearance in the middle.

This is very beneficial for the arrangement of the ejector and ejector plate clamps with the battery system.

Bar: Used to make a divider between the support plate and the clamp plate. Help the propeller to operate smoothly.

Lower clamp plate: Used to hold the entire lower mold assembly into a unified block. At the same time clamp this block to the dynamic table of the plastic injection machine

Push pin: When finished, the mold part will open, this time the push pin will take the product out of the mold

Push clamp plate: Fix the three parts: push pin, return pin and stem puller

Why push plate in the injection plastic mould 2022 is important?

Push Plate helps prevent the mounting pins on the ejector clamp of injection plastic mould 2022 from falling while pushing the product out. This unit is located between the lower die and the lower clamp plate.

What is the function of return latch?

When the mold is closed, the return latch will be the part that helps the propeller to return. The return pin helps to ensure that the clamp plate assembly and the ejector plate do not slip out. At the same time, it protects the ejector battery from bending during the process of pushing the product back and forth.

Function of lower and upper mold plate

Contour determines the internal shape of the product. The lower mold and the upper mold will combine to create the complete shape of the part. The upper die is the stationary part, and the lower die is the movable part of the injection plastic mould 2022.

What is the CNC mold processing?

CNC mold processing is a method of mechanical processing by applying modern CNC (computer numerical control) technology to achieve high accuracy with fast working speed.

In custom CNC mold machining in Hanoi, machines create the part by removing material from a solid block based on the CAD model. CNC produces parts with very tight tolerances and perfect material properties, with high repeatability, contributing to optimal production costs.

Major features of CNC machine

CNC machine is a high-tech machine that is controlled and operated automatically on computer software. The machine works to process products similar to the prototype on 2D and 3D technical drawings. CNC mold machining shows a remarkable improvement compared to conventional machining equipment.

Advantages of CNC machine

- Firstly, produce molds with high accuracy and better repeatability than other machining methods.

- Secondly automation, no need to control the machine manually like traditional machining methods.

- Thirdly, the size and shape of the product is precise, the tolerance level is very small, suitable for high-end requirements.

- Fourthly, the fast machining time.

- Fifthly, the finished mold ensures excellent physical properties and uniformity in different environments.

- Finally, CNC machining is the most cost-effective manufacturing method for producing metal parts in low or medium quantities.

Hopefully with the above article, you have gained some basic information about injection plastic mould 2022.