When it comes to manufacturing precision plastic components, injection moulding stands out as a versatile and efficient method. ACE, a reputable manufacturer, offers a wide range of injection moulding products tailored to various industries and applications. From aerospace to medical, ACE's injection moulding solutions cater to different needs, ensuring top-quality, cost-effective, and reliable products. In this blog, we will explore ACE's diverse product line and discuss how each category fulfills specific industry requirements.

Aerospace Plastic Injection Parts — Precision and Performance: ACE's Aerospace Injection Moulding Products

The aerospace industry demands components that adhere to strict tolerances, withstand extreme conditions, and maintain precision. ACE's Aerospace Plastic Injection Parts rise to the occasion, providing lightweight yet robust solutions. These parts ensure the safety and performance of aircraft, satellites, and other aerospace applications. Whether it's interior cabin components or critical engine parts, ACE's aerospace products are engineered to meet the highest standards.

Automotive Plastic Injection Parts — Driving Innovation: ACE's Automotive Injection Moulding Components

In the automotive sector, reliability and efficiency are paramount. ACE's Automotive Plastic Injection Parts play a pivotal role in enhancing vehicle performance, safety, and aesthetics. From interior trim components to under-the-hood parts, these products undergo rigorous testing to meet industry-specific requirements. ACE helps drive innovation in the automotive world by producing durable, lightweight, and cost-effective solutions.

Cosmetics Plastic Injection Parts — Elegance and Functionality: ACE's Cosmetics Injection Moulding Products

Cosmetic products require not only appealing aesthetics but also functionality and user-friendliness. ACE's Cosmetics Plastic Injection Parts strike the perfect balance between form and function. These components are designed to deliver a seamless user experience while ensuring precise dosage and product protection. ACE contributes to the cosmetics industry by producing elegant and functional packaging solutions that enhance brand value.

Engineering Plastic Injection Parts — Versatility and Durability: ACE's Engineering Injection Moulding Components

Engineering applications often require components that can withstand heavy loads, extreme temperatures, and harsh environments. ACE's Engineering Plastic Injection Parts are engineered to meet these demands. Whether it's industrial machinery, construction equipment, or consumer appliances, these components offer durability and versatility. ACE empowers engineers and manufacturers with reliable solutions that enable innovation.

Home Appliance & Office Plastic Injection Mould — Streamlined Living and Working: ACE's Injection Moulded Home and Office Products

ACE contributes to modern living and working environments by producing Home Appliance & Office Plastic Injection Mould components. These products encompass a wide range, from ergonomic office chair parts to energy-efficient home appliance components. ACE's expertise in injection moulding ensures that these products are not only functional but also aesthetically pleasing, making homes and offices more comfortable and efficient.

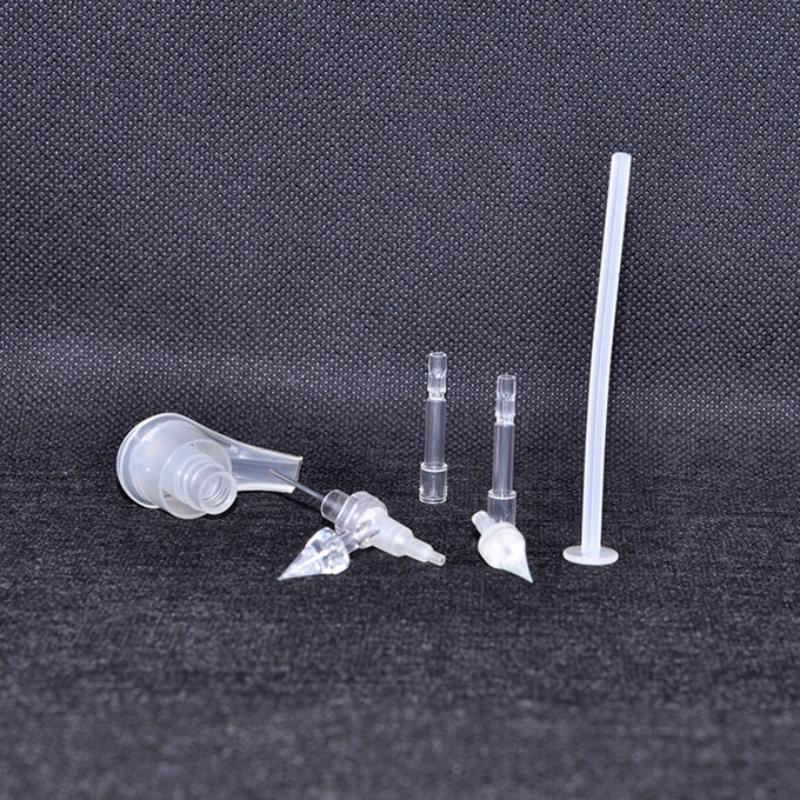

Medical Plastic Injection Moulding — Healthcare Precision: ACE's Medical Injection Moulding Solutions

The medical industry relies on precision and safety. ACE's Medical Plastic Injection Moulding products play a crucial role in healthcare, from intricate medical device components to sterile packaging. These components adhere to the strictest quality standards and are designed to enhance patient care while ensuring the reliability and consistency required in medical applications.

Plastic Injection Insert and Over Moulding — Seamless Integration: ACE's Injection Insert and Over Moulding Expertise

For products requiring multiple materials or components, ACE offers Plastic Injection Insert and Over Moulding solutions. These processes allow for the integration of various materials, such as metal inserts, within plastic components. ACE's expertise ensures a seamless and durable connection, expanding possibilities in product design and functionality.

Thin Wall Plastic Injection Moulding — Lightweight and Efficient: ACE's Thin Wall Injection Moulding

Industries such as packaging and consumer electronics require lightweight yet sturdy components. ACE's Thin Wall Plastic Injection Moulding products excel in providing such solutions. They offer reduced material usage, lower production costs, and excellent structural integrity, making them ideal for applications where weight and efficiency matter.

Two Shot Mould — Complexity in Simplicity: ACE's Two Shot Moulding Capabilities

Complex components often require multiple materials or colors. ACE's Two Shot Moulding process allows the creation of intricate parts with different materials in a single cycle. This technique ensures precision, reduces assembly requirements, and enhances product durability, making it a valuable solution for various industries.

ACE Injection Moulding Products: Shaping the Future of Manufacturing

I. Injection Moulding Products: The Rise of Injection Moulding

Injection moulding is a manufacturing process that involves injecting molten material, typically plastic, into a mould to create intricate and highly detailed parts or products. It has become the method of choice for producing a wide range of items, from automotive components and medical devices to consumer goods and packaging. ACE recognized the potential of injection moulding early on and has continually strived to innovate and provide cutting-edge solutions to meet industry demands.

II. ACE's Innovative Product Range

ACE's injection moulding products encompass a diverse range of components and machinery, each designed to enhance the precision and efficiency of the injection moulding process. Their product portfolio includes moulding machines, moulds, and auxiliary equipment that cater to various industries. ACE's commitment to research and development ensures that its products are equipped with the latest technological advancements, enabling manufacturers to stay competitive in the market.

III. Meeting Industry-Specific Needs

One of ACE's standout features is its ability to customize injection moulding solutions to meet the specific needs of various industries. Whether it's the automotive sector requiring high-strength parts or the medical industry demanding strict cleanliness standards, ACE can tailor its products to deliver consistent and reliable results. This adaptability has made ACE a trusted partner for companies across the manufacturing spectrum.

IV. Sustainable Manufacturing

In today's environmentally conscious world, sustainability is a key concern for manufacturers. ACE understands this and has developed injection moulding solutions that not only optimize production processes but also reduce waste and energy consumption. Their commitment to sustainability has positioned them as a leader in eco-friendly manufacturing, attracting businesses looking to reduce their carbon footprint.

V. Global Reach and Market Impact

ACE's reach extends far beyond its home base. The company's injection moulding products have found their way into markets worldwide, creating a global impact. Manufacturers in Europe, Asia, the Americas, and beyond rely on ACE's products to produce high-quality components and products efficiently. This global presence has solidified ACE's reputation as a trusted and dependable supplier.

VI. Future Prospects

As manufacturing continues to evolve, ACE is poised to play a pivotal role in shaping the future of injection moulding. Their dedication to innovation, sustainability, and customer-centric solutions ensures that they will remain a prominent player in the industry. With a keen eye on emerging technologies, ACE is well-positioned to continue providing cutting-edge injection moulding products that drive progress in manufacturing.

Conclusion

ACE's injection moulding products cater to diverse industry needs, providing reliable, high-quality solutions. Whether it's aerospace, automotive, cosmetics, engineering, home appliances, medical, or specialized techniques like Two Shot Moulding, ACE ensures that each category meets industry-specific requirements. Their commitment to precision and innovation makes them a trusted partner for companies seeking top-notch injection moulding solutions.