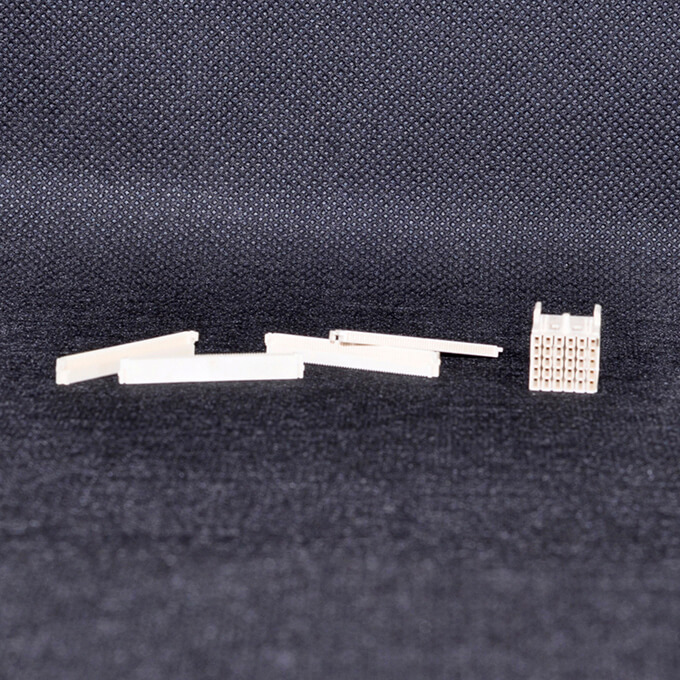

Medical Parts Plastic Injection Moulding

Cosmetics and pharmaceuticals Industrial designers typically focus on function, appearance, and ergonomics. For ACE's design engineers, designing for manufacturability is an important criterion. By utilizing various Medical and Cosmetics tools and concepts such as mould flow analysis, prototyping, scientific moulding analysis, and automation consideration, ACE engineers can eliminate inefficiencies or potential problems during the ramp-up process. Our design and engineering teams are ready to take your medical product ideas and turn them into reality, or to re-engineer existing products for better quality and lower cost.

Many critical manufacturing technologies for the medical goods industry are well-known to ACE, including precision mold making and moulding, high gloss moulding, co-injection moulding, and various surface finishing techniques such as pad printing and electroplating.

Benefits of Medical Parts Plastic Injection Moulding

Medical parts plastic injection moulding is a vital part of the healthcare industry. It is a technique used to manufacture complex medical components and products. This process offers a wide range of advantages, such as high precision, low cost, and fast production. Medical parts plastic injection moulding is an effective and efficient way to produce high-quality medical parts. It allows for a high degree of accuracy, repeatability, and cost-effectiveness. It also enables a wide range of materials to be used and offers a number of benefits over traditional manufacturing methods.

Efficiency: The plastic injection moulding process is an important part of the medical device industry. It is used to produce a wide range of parts, from medical instruments to implants. The process is efficient and cost-effective, but it also has some downsides.

Affordable: Medical parts plastic injection molding is a cost-effective and efficient way to create medical components. This process has many benefits including cost savings, improved design flexibility, and high-quality production. Additionally, it can reduce lead times and improve part accuracy and consistency, making it an attractive option for many medical device manufacturers.

Quality: Medical parts plastic injection molding is an important process in the healthcare industry, as it is used to create medical parts and components of the highest quality. Quality medical parts plastic injection molding requires careful attention to process and materials, as well as precise control of temperature, pressure, and other variables.

Why Choose ACE Group

1. We have a highly experienced in-house design and development team. We are very comfortable and skilled in dealing with our international clients.

2. We provide OEM/ODM services to all types of customers and have professional customer support and project management teams on hand 24 hours a day, seven days a week.

3. We have a strict quality control system in place to ensure that our products are of the highest quality, that we provide the best service, and that our prices are competitive.

4. Quality inspection samples are always available and can be quickly delivered to you.

5. Design ability: create designs that adhere to customer specifications.

6. We deliver goods on time and work transparently with customers.

| Brand Name | ACE |

| Model Number | ACEMED018 |

| Mould Material | 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61, etc |

| Mould Base | FUTABA, LKM, HASCO, Meusburger, DME, Misumi, etc |

| Mould Shaping | Plastic injection moulding |

| OEM/ODM | Acceptable |

| Package | Standard or as your request |

| Standard Delivery | 40 days or 5 weeks |