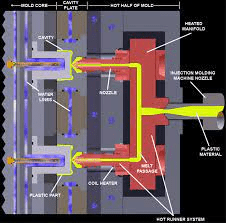

Mold construction:

The hot runner mold common in injection molding technology is joined from many mold plates; the mold plates can be separated to take out the molded object after the injection molding process is completed. Of the mold plates the most important are the two main plates, one for each half shape of the object.

The remaining plates called side mold plate, to pair with details such as the steering column shaft defects, bolts, springs. Molds piece using some different mold, each mold to create a part of a complex object. This is usually only common for large and high value products.

Injection molding support system has 04 main systems

1- Body

This part of hot runner mold consists of a system that links and holds systems and machines parts together to make the machine operate stably and reliably.

2- Hydraulic system:

Providing the force to close and open the die generates and maintains the clamping force causing the screw to rotate and move back and forth giving force to the push pin and the sliding of the side core. This system includes: pump, valve, motor, pipeline and oil tank.

3- Electrical system.

Power supply for the electric motor and thermal control system for the plastic compartment through thermal rings ensures stable operation of the whole system through the wiring and control cabinet.

4- Cooling system

Provide water or ethylene glycol solution to cool the hot runner mold, hydraulic oil and prevent the raw plastic at the hopper from melting, because when the plastic is melted, it is difficult for the upper raw plastic to enter the plastic chamber. The heat exchanger for hydraulic oil is in the range of 90-120 degrees F.

Spray system

The injection system is responsible for putting plastic into the mold through the processes of plastic feeding, compression, degassing, plastic melting, liquid plastic injection into the mold and product shaping. This system has the following components:

1) Plastic feeding hopper:

Contains plastic pellets to feed into the mixing chamber.

2) Plastic compartment:

Contains plastic heated by heating rings

3) Heating rings:

In this part of hot runner mold keeps the temperature in the plastic chamber always in a state of plasticity. On a plastic injection molding machine the heating rings are set to different temperatures to create the right temperature zones for the injection molding process.

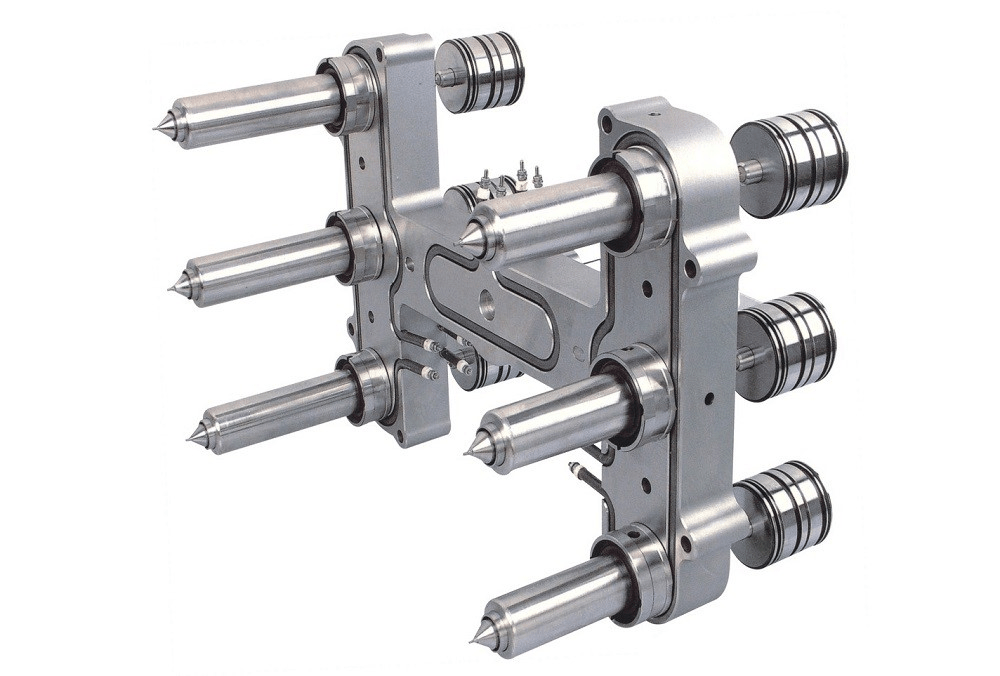

4) Screw:

Has the function of compressing, plasticizing and creating pressure to push the plastic to flow into the mold cavity. The screw has a structure of 3 areas:

- Plastic feeding area

- Compression zone

- Dosing area

5) Self-opening regenerative or self-opening return valve

This unit includes the wedge guard, screw head and seat. As the screw recedes, the wedge-shaped barrier moves towards the nozzle and allows the plastic to flow towards the front of the screw head and when the screw moves forward, vice versa.

Applications for hot runner mold

- Furniture (tables, chairs, cabinets, doors

- Household appliances (Food containers, filtered water bottles, kitchen utensils, trash cans

- Common in industry (Plastic pallets, machine parts, product packaging, paint cans, plastic trays

- Electronic equipment: Laptop case, keyboard, mouse, and other components

- Construction: water pipes, plastic formwork, electrical conduit

- Electricity: wire sheath, switch cover, insulation details

The most popular plastic processing methods today are:

Injection molding technology:

Hot runner mold or molding is the most commonly common manufacturing process for making plastic parts. Plastic is melted in an injection molding machine and then injected into a mold, where it cools and solidifies into a product. Molds common in injection molding are often complex and require high precision.

Extrusion technology:

Plastic extrusion is a process of squeezing molten plastic through an opening of constant cross-section (mold) to form a shape. When the plastic comes out of the hot runner mold, it cools to shape. Extruded products are shaped in 2 dimensions, the accuracy of the product depends on factors such as temperature, pressure, material.

Blow molding technology:

Blow molding is the process of inflating a plastic billet in a hollow mold, so that its shape follows the shape of the mold cavity. The system will then inject air into the workpiece. At this time, the plastic billet expands and adheres to the mold wall to create a shape like the shape of the mold cavity.

There are 2 blow molding methods:

Blow molding: from available plastic preforms by hot runner mold, heated and put into molds to blow.

Extrusion blow molding: molten plastic is extruded into the mold cavity, after the mold is closed, the air blowing process begins to allow the plastic to adhere to the mold wall. This method can produce many kinds of empty products such as plastic bottles, water bottles, children's toys, etc.

Blow Molding Process

Hot runner mold is the process of heating thin plastic sheets to the plasticizing temperature, then putting them into an injection mold to shape. After cooling, the product will have the shape of the mold cavity.

The plastic injection molding process

It consists of following steps.

- The plastic sheet comesin place by a clamping device and heated by a furnace (usually an oven using diffuse or radiant heat) until it becomes plastic.

- Then use air pressure, vacuum or mechanical pressure to act on the plastic sheet so that it is close to the mold cavity.

- Next, the cooler will spew out steam or cool air to reduce the temperature of the plastic sheet.

- Finally, use air pressure to separate the plastic billet from the hot runner mold.

Summary

Throughout your life, you may blame the world or others for not having enough time, money, energy, or resources to accomplish your goals. And, you know, it's a harsh truth that every person in the world has at least one perfect reason why they don't live the way they want.

People who are successful in life don't make excuses. They find ways to overcome obstacles. That's why they always succeed in life.