Are you looking for an innovative and cost-effective way to produce high-quality plastic parts? You’ve come to the right place! Ace Roto Mold has been a leader in rotational molding for over 50 years and is a trusted source for all your rotomolding needs. In this blog, we’ll explore the benefits and advantages of Ace Roto Mold and its rotomolding process. We’ll also share examples of projects and provide helpful tips and tricks to help you get the most out of your rotomolding experience.

What is Ace Roto Mold?

Ace Roto Mold is a leading manufacturer of custom-made plastic parts using the rotational molding process. They specialize in a wide range of items such as containers, liners, tanks, and more. Their products are designed to meet specific customer requirements, whether it’s for a single part or a complex assembly. They’re proud to be a leader in the rotomolding industry and have been providing quality parts to customers for over 50 years.

At Ace Roto Mold, customer satisfaction is their top priority. They strive to provide the best customer experience possible by offering helpful advice and support throughout the entire process. Their team of experts is highly knowledgeable and will work with you to find the best solution for your project. And their quick turnaround time ensures that you get your parts quickly and efficiently.

Benefits of Ace Roto Mold

When you choose Ace Roto Mold for your rotomolding needs, you can be sure that you’re getting a quality product. Their team of experts are highly experienced and can provide you with helpful advice and support throughout the process. They also offer competitive pricing and a wide variety of materials to choose from. Plus, their quick turnaround time means that you can get your parts quickly and efficiently.

Ace Roto Mold also prides itself on its commitment to sustainability. They use eco-friendly materials and processes to reduce their environmental impact. Plus, they’re dedicated to helping their customers reduce their own carbon footprint. So when you choose Ace Roto Mold, you’re not only getting a quality product, you’re also helping to protect the environment.

History of Ace Roto Mold

Ace Roto Mold has been a leader in the rotomolding industry for over 50 years. They have dedicated themselves to providing quality parts and excellent customer service. They’re also committed to staying up-to-date with the latest technologies and processes to ensure that their customers are getting the best possible product.

Ace Roto Mold was founded in 1971 by Paul and Chris Kieffer. They started out as a small family business and quickly grew to become one of the largest rotomolding manufacturers in the US. Today, Ace Roto Mold is a trusted source for all your rotomolding needs.

The Process of Rotational Molding

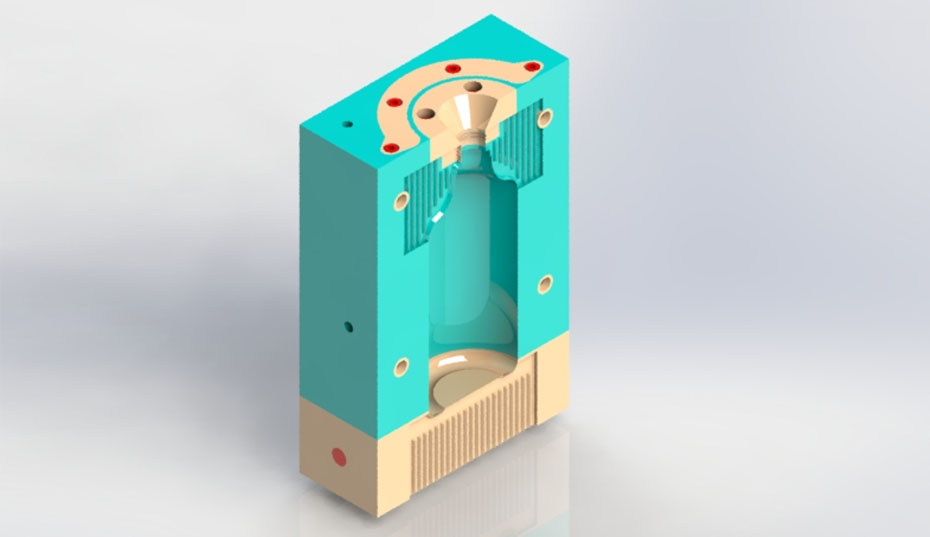

Rotational molding is a process used to create plastic parts. It involves heating a plastic material and then spinning it in a mold. The heat and pressure create a uniform wall thickness and give the part its desired shape. This process is used to create a wide range of items, from toys to tanks.

The process begins with the creation of a mold, which can be made from a variety of materials including aluminum and steel. The mold is then heated to a certain temperature and filled with a plastic material. The mold is then placed on a rotating machine and spun, allowing the plastic to evenly coat the entire surface of the mold. Once the plastic has cooled and hardened, the part is removed from the mold and is ready for use.

Advantages of Rotomolding

Rotomolding has many advantages over other manufacturing processes. It’s a cost-effective process that can produce parts quickly and efficiently. Plus, the process is highly customizable, allowing you to create parts with complex shapes and intricate details. The process also reduces waste, as the plastic is evenly distributed in the mold and there’s no need for additional material.

Rotomolding is also a highly durable process. The parts created are highly resistant to shock, vibration, and chemicals. This makes them ideal for use in a wide range of applications, from medical equipment to outdoor furniture.

How Ace Roto Mold Can Help Your Business

At Ace Roto Mold, they understand that rotomolding is a complex process. That’s why they offer a wide range of services to help their customers get the most out of their rotomolding experience.

First, their team of experts can provide helpful advice and support throughout the process. They can help you choose the right materials, create a mold, and design a part that meets your exact requirements. Plus, their quick turnaround time ensures that you get your parts quickly and efficiently.

Ace Roto Mold also offers a variety of other services, such as prototyping, mold-making, and assembly. They can even provide custom packaging to make sure that your parts are delivered safely. So no matter what your needs are, Ace Roto Mold is here to help.

Examples of Ace Roto Mold Projects

Ace Roto Mold has been producing high-quality parts for over 50 years. They’ve worked on a wide range of projects, from small individual parts to complex assemblies. Here are some examples of projects that Ace Roto Mold has completed:

• Tanks – Ace Roto Mold is a leader in the production of tanks for a variety of applications. They can produce tanks from a variety of materials, including polyethylene and polypropylene.

• Containers – Ace Roto Mold also produces a wide range of containers, from small storage containers to large tanks. They can create containers with complex shapes and intricate details.

• Liners – Ace Roto Mold can produce liners for a variety of applications, including fuel tanks and water tanks. They can create liners that are highly resistant to corrosion and other environmental factors.

• Toys – Ace Roto Mold produces a wide range of toys, from simple figurines to complex action figures. They can create highly detailed toys with intricate shapes and designs.

Ace Roto Mold Resources

At Ace Roto Mold, they understand that rotomolding is a complex process. That’s why they offer a variety of resources to help their customers get the most out of their rotomolding experience.

They offer a range of helpful tutorials, from basic to advanced rotomolding techniques. Plus, they have a variety of helpful videos and articles to help you learn more about the process and get the most out of your rotomolding experience.

Ace Roto Mold also has a blog where they share the latest news and updates on the rotomolding industry. They also share helpful tips and tricks for getting the most out of your rotomolding experience. So no matter what your needs are, Ace Roto Mold has the resources to help you.

Rotational Molding Tips and Tricks

Rotomolding is a complex process, but with the right tips and tricks, you can get the most out of your rotomolding experience. Here are some helpful tips and tricks to keep in mind:

• Choose the right materials – Make sure to choose the right materials for your project. Different materials have different properties, so it’s important to choose the one that’s best suited for your needs.

• Keep detailed records – Keeping detailed records of your process is essential. This will help you track your progress and identify any issues that might arise.

• Test your parts – Make sure to test your parts before using them. This will help you identify any potential issues and ensure that your parts meet your standards.

• Seek help – If you’re having trouble, don’t hesitate to seek help. Ace Roto Mold’s team of experts is highly knowledgeable and can provide you with helpful advice and support throughout the process.

Conclusion

Rotational molding is a complex process, but Ace Roto Mold is here to help. Their team of experts is highly experienced and can provide you with helpful advice and support throughout the process. Plus, they offer competitive pricing and a wide variety of materials to choose from. So if you’re looking for an innovative and cost-effective way to produce high-quality plastic parts, look no further than Ace Mold.