What is medical injection molding?

Fabricating therapeutic components and gadgets utilizing restorative review plastic materials that are tough, dependable, and meet FDA controls is the pith of medical infusion molding. Different medical mold has an implementation in this strategy.

The restorative plastic infusion molding method is expense efficient, and perfect for tall volume generation runs and practices requiring consistency and tight resistances. Additionally, this molding method has utilization for restorative gadget model advancement for FDA endorsement method and for using in research facility testing.

What are medical device plastic injection molding materials?

The restorative grade plastic material we utilize for restorative infusion molding has a tall atomic weight and highlights chemical and warm safe properties. A medical mold of different kinds is employed in this technique to manufacture various medical plastic infusion molds.

Moreover, each sort of thermoplastic utilized for restorative molding highlights diverse points of interest and qualities you may need to audit some time recently selecting a fabric for your infusion molding practice.

What are polycarbonate materials?

These materials are transparent and have common employment for therapeutic tubing. This therapeutic grade plastic highlights tall pliable, and shear, as well as flexural quality. It too gives tall warm resistance, moo dampness assimilation, and it is more ground than acrylic.

What are PEEK materials?

PEEK stands for polyether ether ketone. It is an outlandish restorative review plastic resin that’s exceedingly safe to plastic chemicals, stands up to breaking and weakness, and can be sterilized through the autoclave. Additionally, it has an FDA endorsement for food contact and contains a UL 94 V-0 combustibility rating.

What are Ultem materials?

This material has employment in medical gadgets and one can sterilize this through the autoclave. It stands up to natural push and splitting, gives fabulous dimensional solidness, and shows prevalent quality and firmness.

What are the applications of medical device plastic injection molding?

Applications of using plastic medical mold infusion are following.

- Dental instruments

- Surgical instruments

- Needles

- Prosthetics and

- Blades as well as

- Medical enclosures along with other medical components

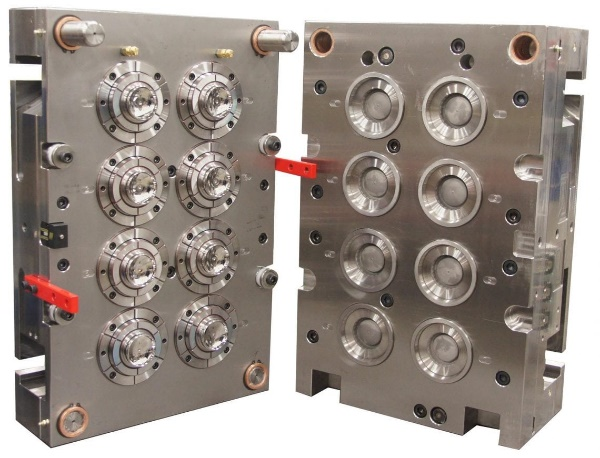

(A plastic medical mold)

What are the seven key strategies behind enabling connected workers in medical product manufacturing?

Whereas information democratization has ended up the foundation of what characterizes an associated laborer, it isn’t a solid concept. Instep, there are several ways this has effectively been put into hone. Laborers operate machines and medical mold to create various therapeutic apparatuses.

Let’s look at the seven key procedures being actualized by those producers who have been effectively turned and extended their business to meet fast spikes in a request for therapeutic items and components.

1. Smarter, better sensors

Producers are expanding their buys of smart machines that can report on generation, utilization, and wear, as well as vitality, utilization, among other measurements. These companies are too retrofitting their existing apparatus with smart sensors that essentially give important information for making strides in generation productivity and item quality.

2. Real-time analytics

Transitioning to an associated specialist approach for smart manufacturing starts with solid information that gives producers new, frequently starting bits of knowledge into expanding generation proficiency and quality.

Outstandingly, real-time analytics are going past gaging the current status to empowering prescient examination for surveying dangers to generation and the effect on income. With the coming about exceedingly, exact deals and edge figures, the producer can assist progress their financial visibility.

3. Touchscreen base shop floor interfaces

Laborers on the shop floor require frequent access to data from ERP (enterprise resource planning) and fabricating frameworks to progress generation and proficiency. The modern natural client interfacing too offer assistance digitize fabricating operations and progress generation proficiency.

The more up-to-date course of natural touchscreen shop floor interfacing offers assistance to obscure the line between laborers and these frameworks by streamlining information access and real-time data collection and accessibility in arrange to move forward quality and decrease costs.

4. Digital workflows

Information access is basic, but as well regularly overburden leads to delay in beginning up unused generation in runs. Present-day shop floor interfacing direct laborers through the fair data they have to be set up their stations, total their errands, and screen and recognize any potential issues in generation or quality.

The workflows may serve as a checklist for experienced representatives or as on-the-job preparing for laborers modern to the task. Moreover, keep in mind that, digital workflows should be minimum in the manufacturing of a medical mold.

5. Remote access in manufacturing

Farther to get demonstrated priceless in 2020, and it’ll proceed to be the main point to keeping supply chains, generation planning, shipping, and client benefit moving. Through inaccessible get to ERP and fabricating frameworks, a representative in details, bookkeeping, and other back-office capacities may proceed to conduct commerce as regular.

That realization has driven numerous producers to reconsider onsite staffing arrangements and utilization of their offices. Also, it got to be clear that numerous offices did not require staff onsite to screen machines and instep seem to oversee numerous destinations from a single control center for prominent proficiency.

6. Quoting and pricing

By upgrading arrange, cost, site (CPQ) prepare without outwardly compelling cites of custom-configured restorative items utilizing three-dimensional pictures. Therefore, producers are moving forward their cost administration control over channels and expanding edges, as well as diminishing the arrange mistakes within the method.

Since more producers move into more advanced channels in 2021, having a streamlined CPQ handle will get to be a competitive advantage. Foundation to victory with CPQ will be receiving design to manufacturing, processing item quality, and expanding abdicate yield.

7. Digital training tools

Following the world economic forum, advanced preparing devices will diminish preparing time by almost 75%, assist expanding the skill and information of generation group individuals over areas. Finally, in this manner, therapeutic gadget producers need to make computerize preparing programs to instruct fundamental instructions to laborers.

What should consider before selecting a medical mold?

Here is the name of some considerations that you should keep in mind before selecting the medical mold.

- Resistance to chemicals and heat

- FDA requirements

- Operating environment and

- Strength and durability as well as

- Molding process

What are the benefits of using a medical mold?

Since medical gadgets plastics give good flexibility, and are able to combine with metal to make better therapeutic items. A few preferences that medical mold companies can give incorporate these.

Plastic medical molding reduces the weight of therapeutic gadgets. Additionally, it has lower expense over other therapeutic devices. Its sterilization is much easy due to which it decreases the burden of sterilization. Moreover, it increases functionality because of innovation with time. Finally, it improves ergonomics.