The cost of tooling manufactures services of the same product in different units will have certain differences. Generally, this depends on many factors. In this article, we will clarify which factors the cost of CNC tooling is affected by, thereby helping businesses no longer worry about the price difference.

Factors affecting the cost of tooling manufactures

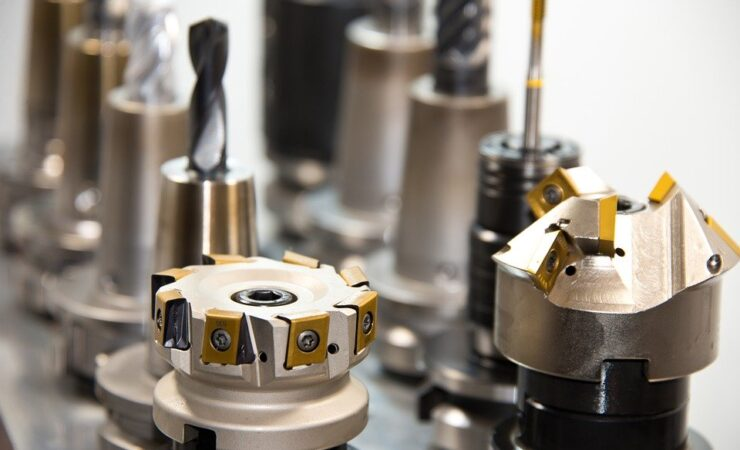

CNC tooling is a method of removing material to produce parts. It can be common to create the necessary parts from a variety of materials, including metals and plastics. Basically, the cost of CNC tooling depends on the following factors:

Material of the part to be processed

The choice of material is one of the factors affecting the cost of tooling manufactures, reflected in two aspects: the cost of raw materials and the ability to process materials.

Generally, each type of material has different characteristics and properties. Moreover, this comes on the characteristics of the product you want to create and the design requirements. Furthermore, the processing unit will choose the most suitable material with the most reasonable price. There are materials that are easy to process, but besides that there are many types of materials that are difficult to meet the requirements that we want.

Complexity of the design of tooling manufactures

If the tooling manufactures to be formed has a complex structure, it will require a high level of design, which leads to price differences between products of the same size and material.

Complicated parts will require a lot of tooling operations, thereby prolonging the CNC tooling time, so the tooling cost will also increase significantly. A part that is processed on multiple machines will inevitably cost more than if the part only needs to be machined on one machine.

Dimensions of the part to be processed

The overall size and shape of the part to be CNC machined is an important factor affecting the tooling cost. The larger the size, the more materials required and the longer the processing time.

Finishing process

Many CNC machined products require additional treatments, such as surface finishes, heat treatments, special tooling operations, and specialized coatings. All these requirements need proper assessment for their necessity and value. These are factors that will increase the cost of tooling manufactures.

Tooling manufactures Order quantity in each order

For bulk orders, it will help increase production efficiency and reduce CNC tooling costs. This helps to reduce product costs significantly. We understand that, any costs for design, CAM programming, setup time, material costs and custom fixtures or fixtures to fabricate may come with an allocation. For a large number, which helps to break down the cost per part?

Product Tolerance

Tolerance is also one of the factors that significantly affect the cost of CNC tooling. If the customer requires a tight tolerance; the tooling cost will be higher. In general, if tolerance requirements are not tight, even a small change can reduce costs. Compulsory and strict tolerance requirements mean that the design and manufacturing process will require more time and effort.

Using plastic injection molds is the most effective and popular method of the production process of plastic products in today's society. In other words, the benefits of tooling manufactures in the manufacturing industry are enormous. We will find out together in the article below.

Benefits of plastic injection molds in the manufacturing industry

In each plastic injection cycle, the plastic materials melt, and they go into mold cavity. Later it comes out of the mold with a definite shape. Using this method we can get plastic products easily.

The method of using plastic injection molds in injection molding brings many benefits that are far superior to other production methods.

Tooling precision

Plastic injection molding is an extremely accurate measure. It can be common in processing most types of plastic products on the market today. The advantage of tooling manufactures mold in injection molding is to create products with extremely high accuracy. The deviation is in the range of less than 0.005inch.

Fast pressing speed

Plastic injection molding is leading production technology because of its fast injection speed. Depending on the complexity of the mold, the time of each injection cycle only ranges from 15 to 30 seconds. This is an extremely ideal number for mass production of plastic products in large quantities, requiring time short.

Low labor cost

The equipment common in injection molding is often highly automated, operating on modern equipment lines. Therefore, the production process still takes place smoothly and continuously. Similarly, it does not require much use of labor. In addition, it minimizes production supervision, thus significantly saving labor costs.

Sustainability, flexibility in production

After coming into production, plastic materials will generate a large amount of waste. Tooling manufacturers recycle them for the purpose of producing suitable plastic products. This is one of the benefits of plastic injection molds. Moreover, this is a decisive factor in the sustainability of production, both saving costs and minimizing adverse effects on the environment.

The production process of tooling manufactures is completely flexible, the production unit can easily change the type of material, color as well as the additive composition of the desired product.

Suitable for production of products with good properties

Plastic injection molding is suitable for the production of plastic parts with high requirements for some physical and chemical properties. Plastic materials mix with the appropriate formula to produce a plastic with good elasticity, toughness, heat resistance...

Meet the aesthetic requirements of plastic products

Plastic injection molds are common in injection molding to produce plastic products that meet the requirements of the business, with high aesthetics. With eye-catching appearance, diverse colors, durability, high glossiness, and tooling manufactures s are more and more popularly common in daily life. This is gradually replacing products made from different types of materials is different.

Long-term production service

The original plastic injection mold created requires quite high manufacturing and processing costs. However, plastic injection molds are useful for long-term production. This creates a series of plastic products with uniform quality. Moreover, it significantly saves costs for the entire production process.

The use of plastic injection molding machines brings outstanding efficiency. This comes by the ability to process many different types of plastic materials at the same time. Plastic injection molding is common as a popular plastic production technology with the highest applicability today.