In manufacturing applications, the quality of parts is highly dependent on the surfaces remaining within desired roughness limits. Surface finishing plays a crucial role in ensuring the durability and performance of the final product. To achieve the desired surface finish, it is essential to have a clear understanding of the surface roughness chart and its importance. This comprehensive guide will provide you with all the necessary information to navigate the world of surface roughness and make informed decisions to optimize your manufacturing processes.

What is Surface Roughness?

Before delving into the surface roughness chart, it is important to understand what surface roughness entails. Surface roughness refers to the measure of the total spaced irregularities on a product's surface. It is often used interchangeably with the term "surface finish." The surface roughness of a material affects its wear resistance, friction levels, adhesion properties, and overall performance.

Surface roughness is characterized by three key components: surface roughness, waviness, and lay. Surface roughness refers to the measure of the total spaced irregularities on the surface. Waviness refers to the warped surface whose spacing is greater than that of surface roughness length. Lay refers to the direction the predominant surface pattern takes.

Importance of Surface Finish in Engineering Processes

The surface finish of a product plays a crucial role in determining its functionality and performance in various applications. It affects how a product interacts with its environment, influences the adhesion of coatings and paints, and impacts the product's resistance to corrosion and wear. Surface finish also has aesthetic implications, as it contributes to the visual appeal of the final product.

Maintaining the desired surface finish is essential for producing consistent processes and reliable products. It helps ensure the longevity, functionality, and overall quality of the manufactured parts. Different surface finishes have varying effects on the performance of the product, and understanding the surface roughness chart is the key to achieving the desired results.

Understanding Surface Roughness Measurement

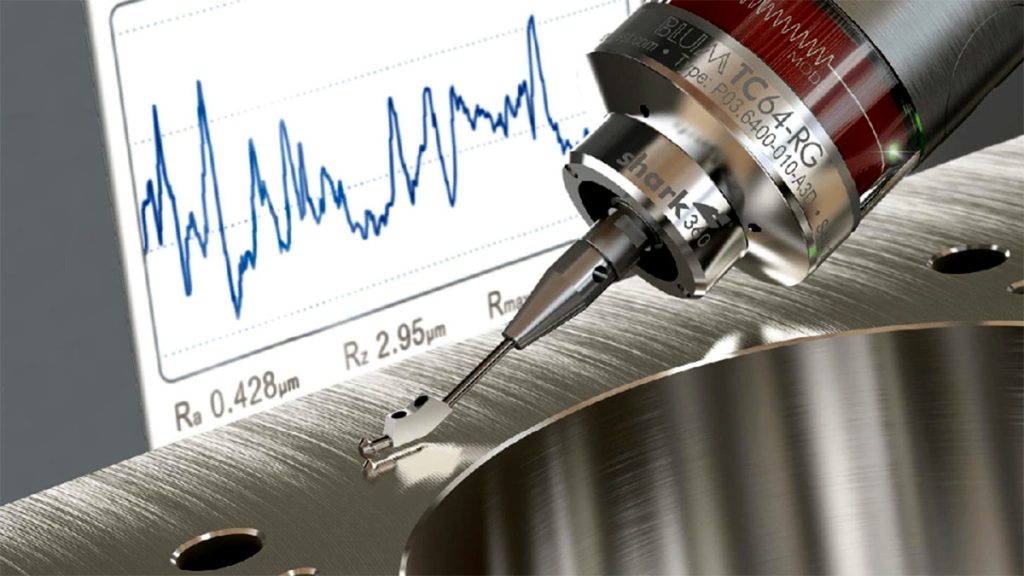

Surface roughness is measured using various techniques and parameters, with the most common parameter being the arithmetic average roughness (Ra). Ra is the measure of the average roughness between a roughness profile and the mean line. It provides valuable information about the height and distribution of peaks and valleys on a surface.

There are several methods for measuring surface roughness, including direct measurement methods, non-contact methods, comparison methods, and in-process methods. Direct measurement methods involve using a stylus to measure the surface roughness by drawing the stylus perpendicular to the surface. Non-contact methods utilize light or sound to measure the surface roughness, while comparison methods involve comparing the surface roughness of a sample with known roughness parameters. In-process methods, such as inductance, use electromagnetic energy to gauge surface roughness.

Methods of Measuring Surface Roughness

There are different methods and equipment available for measuring surface roughness, and the choice of method depends on the specific application and requirements. The measurement methods can be categorized into three main techniques: profiling techniques, area techniques, and microscopy techniques.

Profiling Techniques

Profiling techniques involve the measurement of the surface using a high-resolution probe. These techniques provide precise measurements of surface roughness by considering the sensitivity of the probe. Examples of profiling techniques include the use of a CNC probe or a specialized profiling instrument.

Area Techniques

Area techniques measure a finite area of the surface, providing a statistical average of the peaks and valleys. These techniques are often easier to automate and execute. Some examples of area techniques include ultrasonic scattering, optical scattering, and capacitance probes.

Microscopy Techniques

Microscopy techniques rely on qualitative measurements of contrasts to provide information about the peaks and valleys on surfaces. These techniques are useful for visual inspection and characterization of surface roughness.

Surface Roughness Chart Symbols and Abbreviations

The surface roughness chart uses various symbols and abbreviations to represent different surface finish parameters. These symbols and abbreviations help in understanding and comparing surface finishes. Some of the commonly used symbols and abbreviations in the surface roughness chart include:

- Ra: Average Surface Roughness

- Rmax: Vertical Distance from Peak to Valley

- Rz: Average Maximum Height of the Profile

By referring to the surface roughness chart, designers and manufacturers can determine the specific surface finish requirements for their products and ensure consistency in the manufacturing process.

Surface Roughness Chart: A Comprehensive Reference Material

The surface roughness chart serves as a valuable reference material for manufacturers to ensure the quality and consistency of their products. It provides guidelines for measuring standard surface finish parameters and helps in selecting the appropriate manufacturing processes to achieve the desired surface finish.

The chart categorizes different manufacturing processes based on their relative surface finish roughness. This information assists designers and machinists in choosing the most suitable process to achieve the desired surface finish cost-effectively. Here is an overview of the relative surface finish roughness of various manufacturing processes:

| Manufacturing Process | Relative Surface Finish Roughness |

|---|---|

| Flame Cutting | High |

| Grinding | High |

| Turning | Medium |

| Milling | Medium |

| EDM (Electrical Discharge Machining) | Medium |

| Laser Cutting | Low |

| Waterjet Cutting | Low |

Note: The surface finish roughness may vary depending on the specific parameters and conditions of each manufacturing process.

Choosing the Right Surface Finish for Your Application

The selection of the appropriate surface finish for a particular application depends on several factors, including the function, use, and operating parameters of the component. Designers aim to specify surface finishes that are as coarse as possible while still meeting the desired operating parameters. This approach ensures cost-effectiveness in manufacturing while maintaining the required functionality and performance of the parts.

Machinists play a critical role in achieving the specified surface finishes. It is essential for designers and manufacturers to agree on the specific parameters (such as Ra, Rz, etc.) to be used for inspecting and accepting the parts. By using the same parameters as the designer, machinists can ensure the best results and align their manufacturing processes with the desired surface finish requirements.

Tips for Achieving Optimal Surface Finish

To achieve the desired surface finish, machinists can implement various strategies and techniques. Here are some tips to consider:

- Tool Selection: Choose cutting tools with appropriate geometries and radii to achieve the desired surface finish. Consider using inserts with larger radii or specialized cutters for specific applications.

- Feeds and Speeds: Adjust the feeds and speeds to achieve a lower chip load, which can result in a better surface finish. Optimize the cutting parameters to minimize vibrations and tool deflection.

- Cutting Strategy: Use appropriate cutting strategies, such as light finishing passes, to minimize rubbing and improve surface finish. Implement trochoidal milling or adaptive milling techniques for smoother cuts.

- Coolant and Lubrication: Use coolant or lubrication to reduce friction and heat generation during machining. Proper cooling can help improve surface finish and extend tool life.

- Surface Preparation: Ensure the workpiece is properly prepared before machining to minimize surface defects. Consider pre-machining steps, such as milling or grinding, to achieve a more uniform surface.

- Optimal Stepover and Tool Diameter: For 3D profiling operations, choose an appropriate stepover and tool diameter to minimize scallops and achieve a smoother surface finish. Use G-Wizard Calculator or similar software to determine optimal parameters.

By implementing these tips and techniques, machinists can enhance their ability to achieve the desired surface finish and meet the specifications set by the designer.

Conclusion

Understanding the surface roughness chart is essential for achieving the desired surface finish in manufacturing applications. Surface finish plays a critical role in the performance, functionality, and aesthetics of the final product. By referring to the surface roughness chart, designers and manufacturers can select the appropriate manufacturing processes, specify the required surface finishes, and ensure consistency and quality throughout the manufacturing process.

Machinists play a vital role in achieving the specified surface finish, and by following best practices and utilizing appropriate tools and techniques, they can meet the desired surface finish requirements effectively and efficiently. By working collaboratively and aligning their processes with the surface roughness chart, designers and machinists can optimize the manufacturing of parts and deliver high-quality products to meet the needs of their customers.

Remember, surface finish is not just a technical specification, but it also contributes to the overall performance and perceived quality of the product. With a solid understanding of the surface roughness chart and the ability to achieve the desired surface finish, you can elevate your manufacturing processes and deliver exceptional products in a competitive market.

Additional Information: Surfaces in manufacturing applications must remain within desired roughness limits to ensure the optimum quality of parts. Surface finishing has a crucial impact on the durability and performance of the product. Therefore, it is essential to learn about the surface roughness chart and its importance.