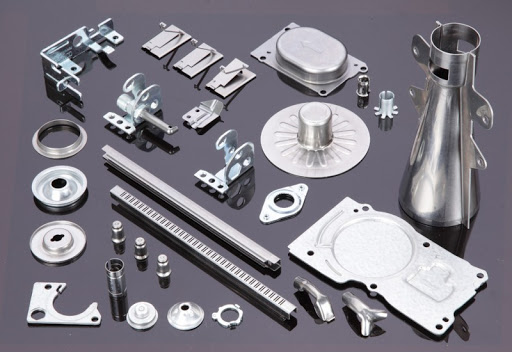

The technology applied in metal folding bending is very modern. As a result, precision metal component manufacturers used it to create diverse and precise shapes.

What is CNC folding that precision metal component manufacturers use?

Sheet metal folding bending processing: is no longer a strange processing technique for us. Folding bending is the act of deforming metal in the form of bending or bending flat metal sheets into different angles and angles as required.

The 3 popular techniques used by precision metal component manufacturers

Current bending techniques include;

1. Air bending technique:

In this form, the metal is taken up and forms an angle when the bending knife presses down; the bending knife presses the metal workpiece into the mold, not the die as usual.

The deeper the strike, the sharper the angle formed on the metal.

So, precision metal component manufacturers use it to create precision metal components.

2. Bending technique (Bottoming):

The bending knife will press the metal workpiece completely into the die, at this time when making the knife and the die, it is necessary to have similarities, the product is shaped stably.

3. Edge bending technique (bending, metal edge):

Each bending technique has different characteristics, suitable for different types of bending. Therefore, depending on the product, the technician will choose the appropriate folding technique.

The system of modern CNC cutting and punching machines helps ensure high-quality accuracy to meet all customer requirements. When you come to our ACEMOLD, you will save production time and increase the efficiency of your work.

With a strict sheet metal processing process, precision metal component manufacturers work on the basis of mechanical capacity, a system of modern equipment, a team of professional engineers and mechanics ensures the quality of CNC cutting - CNC bending services.

best for customers in the fastest time and most reasonable price.

Why should precision metal component manufacturers use CNC bend machining?

Modern facilities, equipment and machinery. Precision Engineering Company, we understand that: Investing in modern factory systems, equipment, and machinery is an investment in product quality.

On-demand CNC folding

- Laser cutting of metal plates

- Metal CNC bending

- Producing & processing metal products for mechanical, industrial, construction, interior, advertising industries....

Aluminum CNC folding press

Accurate – fast – committed on demand

- Machining CNC bending precision metal stainless steel, iron, steel, metal ... with high hardness.

- Accurately perform difficult and complex details such as bends, V-grooves.

- Guaranteed to easily bend metal CNC to any shape required by the customer.

- Processing difficult, delicate details that other equipment cannot do.

- Precision metal component manufacturersuse it as its processing time quickly saves time for customers.

Why precision metal component manufacturers rely on it?

With quality production capacity, competitive price, ACEMOLD sheet metal processing is common by many units with the advantages: Fastest - Most accurate - Most economical. Satisfying the number of orders flexibly, the products of complex machinery details of customers…

Quotation for metal CNC folding bending

The cost of metal CNC bending cutting depends on many factors such as customer requirements, complexity, product structure, materials, technology, etc. Customers! Please contact the ACEMOLD engineer for more details about the quotation for CNC metal folding bending.

What does ACEMOLD address sheet metal provide?

ACEMOLD addresses sheet metal processing, CNC cutting, CNC folding, CNC metal cutting with the best quality and at an affordable price suitable for all customers. Besides, we have a team of engineers who have experience to the sheet metal processing industry.

ACEMOLD precision metal component manufacturers always want to develop and bring to customers the best quality and most prestigious products.

Safety issues when working with metal components are of great concern to many people. Therefore, we would like to share our experiences to help you avoid unfortunate risks when using a metal component.

Hope this information will be useful for you to read!

Assessment’s precision metal component manufacturers prepare before the shift

Before starting work, workers must wear protective clothing. The requirement is to be neat, buttoned at the wrist, or rolled up past the elbow.

Moreover, you must put your shirt in your pants, wear Bata shoes or wear sandals with straps to ensure absolute safety. If you are a female, you must tie your hair neatly and put it in a hat, to avoid entanglement in the lathe machine when operating.

The next step taken by precision metal component manufacturers

The next precision metal component manufacturers have to do is to carefully check the machine again: the work is open; the controls and brakes are in good working order or not.

When detecting any problem or damage, must immediately notify the superior for timely handling, repair, or replacement.

The working place of the metal components also needs to be cleaned and arranged in a neat and clean manner. Items on the machine and around that area should be kept tidy.

Why the barrel should be lubricated?

In the sliding part and the barrel we must lubricate, the pedestal and momentum must not be too large when sharpening the knife, the side of the stone should not be sharpened, and the knife should not be pressed firmly against the stone.

In addition, precision metal component manufacturers describe that it is necessary to cover the front with glasses or mica to help prevent dangerous particles from entering the eyes.

2. During working with metal components

It is necessary to arrange the tools in a scientific way, not to let heavy objects press on the calipers, micrometers, dials, etc. If you use a fixed center, you should put grease in the center hole of the workpiece and carefully check the part.

Use safety glasses to cover the cutting area, ensuring safety when the metal components are in operation. When removing chips from the surface of the part, do not use your hands, but use the chip breaker on the knife or use the hook to remove.

You must not measure and brake, the chuck or workpieces by hand because it is very dangerous.

After completing the threading process

When precision metal component manufacturers complete the threading process, we need to stop the machine and the lever adjusted to the safe position, disconnecting the power. Then clean the chip on the tool holder with a brush and wipe the measuring tool with.

Conclusion

After working, stop the machine, adjust the handle of the machine to a safe position, and disconnect the power from the machine. Use a brush to clean the chips on the tool holder and the machine belt and arrange them neatly in the prescribed position. Then lubricate the work surface on the handover and machine belt.

Finally, handing over the lathe and reporting its status to the person in charge.