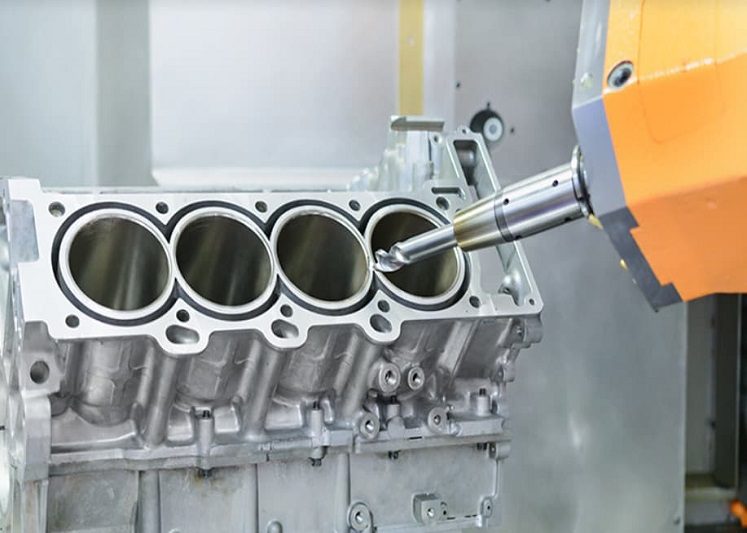

High Precision CNC Components Machining

ACE can provide customers with precision parts processed according to their drawing tolerance requirements using high-precision machining equipment. The parts are 100% compliant with the specified tolerance requirements on the drawings. We also provide inspection reports, machining process reports, and steel material certifications.

- Tolerances as Precise as : +-0.002mm

- Provide fully dimension report

- Provide steel Certificate

- Provide Heat treatment Certificate

- Provide DLC Plating and Nitrding Coating

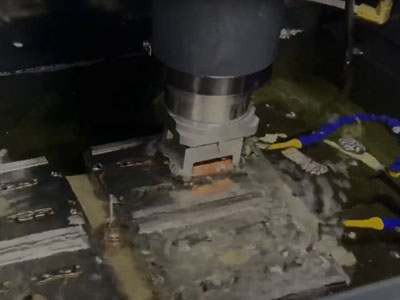

CNC MACHINE

EDM MACHINE

WIRE EDM

CMM MACHINE

ACE Customs Precision Components Machining Services

ACE with over 20 years of experience** in precision machining, we delivers completely precision component solutions for our client. We machine a wide range of materials which including steel, Aluminum, Alloys, Coppers etc. we do fully inspection per customer provided drawing, make sure 100% dimensions in tolerance. Ace we strictly checks every stage from CNC machining, Wire EDM, Mirro EDM, Turning & Milling Precision Grinding etc. We provide also Heat treatment, DLC coating, Nitriding plating , Electroplating machining process, and we will provide the relative certificate as well.

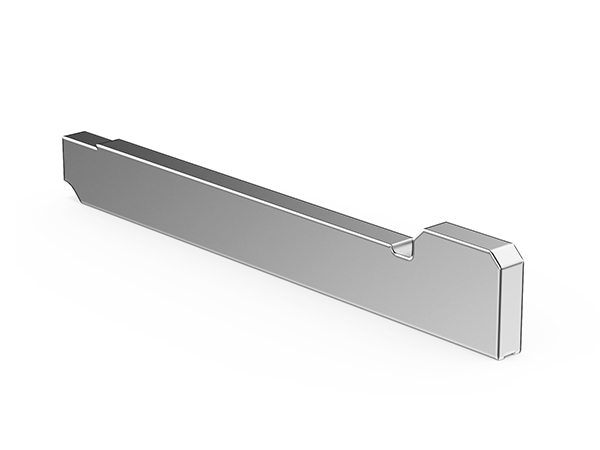

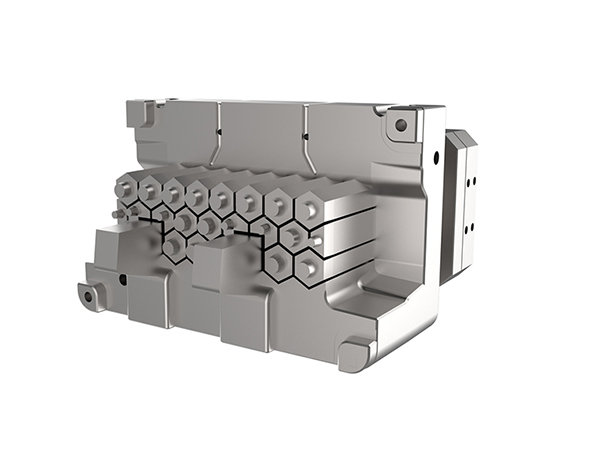

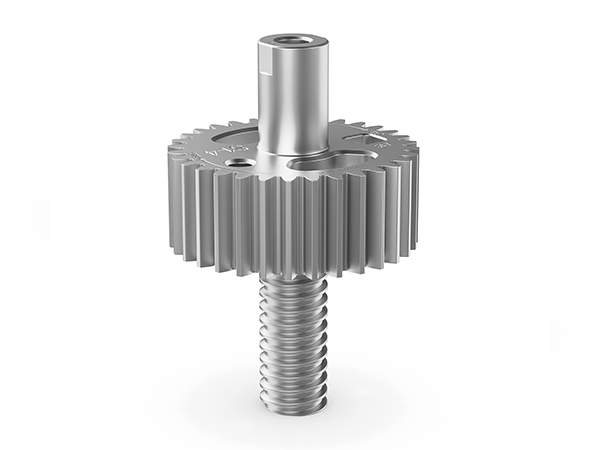

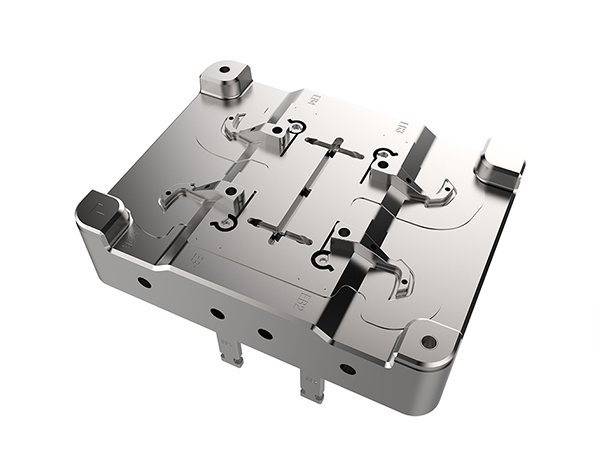

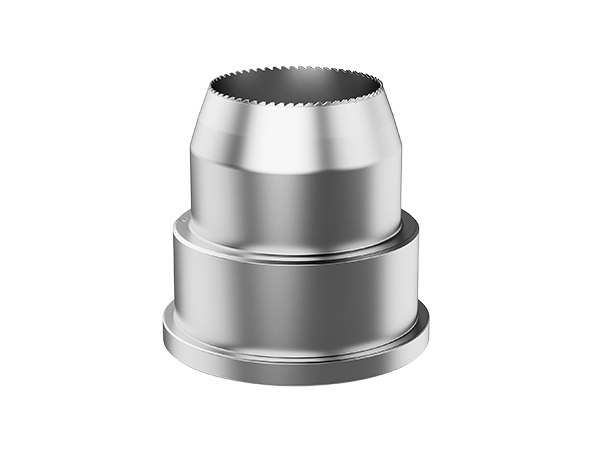

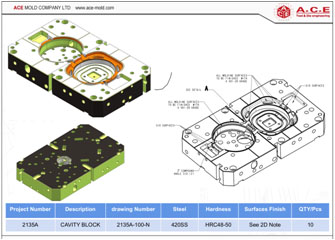

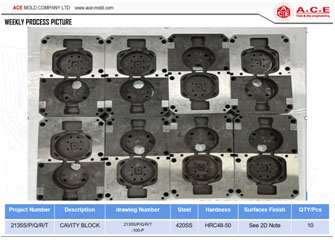

Precision CNC Components Case

From Microns to Miles: Precision CNC Components That Power the World’s Most Demanding Industries.

Precision CNC Components FAQ

Precision CNC components are highly accurate parts produced using CNC machines, meeting tight tolerances for industries like aerospace, automotive, and medical. We offer various materials, finishes, and certifications, ensuring high-quality results. Lead times are flexible, and we support both low and high-volume production runs.

CNC high precision machining center

What types of materials can be used for CNC machining?

What are the typical tolerances for precision CNC components?

How long does it take to produce precision CNC components?

Lathe machining center

Custom Precision CNC Components Solutions

Discover our injection molding services available on-demand, designed to effortlessly guide you from the prototyping phase to high-quality production

Mirror Spark Machine

High-precision EDM machine for mirror-finish surfaces, ideal for mold & die polishing with ultra-fine spark technology.

Wire Cutting

CNC-controlled wire EDM machine for precision cutting conductive materials with thin wire & high accuracy.

Grinding Machining

We provide high precision grinding milling service for small and big size part grinding machining

Heat treatment process

We can provide Heat treatment and Plating, Coating service. Also Hardening treatment

Materials for Precision CNC Machining

ACE provides a selection of standard metals for injection molding tooling, along with an array of widely-used plastic materials

- Metals

- Thermoplastic

- Thermoset

Metals

Additional materials are available based on vendor inventory or by request, but quotes can take up to 48 hours. *Materials softer than 50 Shore D and harder than HRC 32 not offered

- Aluminum,Copper,Brass,Bronze,Steel,Tool Steel,

- Stainless Steel,Titanium,

- Mild Steel (sourced through network),Inconel (sourced through network)

Thermoplastic

Plastic injection molding service comes with a wide range of materials with different properties, including impact strength, rigidity, thermal resistance, chemical resistance, etc.

- ABS HDPE LDPE PP

- PPA PS POM PC

- PU Teflon (PTFE) Nylon

- PC PMMA PA PEEK

- PET

Thermoset

We offer a range of thermoset materials, each suited for different applications thanks to their specialized bonding characteristics.

- Liquid Silicone Rubber Epoxy

- Polyurethane Phenolic

Note: You can learn more from our eBook on plastic materials.

Components processing in ACE

Ace we are able to provide customer completely solution for the components manufacture, see What we can achieve in ACE for the machining processing

| High speed CNC | Over 40000 RPM/min |

|---|---|

| Mirro EDM machining | Surface can reach under Ra0.1 |

| Wire EDM machining | Tolerance ±0.001mm |

| Grinding machining | Tolerance Ra0.01-0.02μm. |

| Lathe machining | Tolerance ±0.001mm |

| CMM Inspection | Inspection tolerance ±0.001mm |

| In-house Turning | 10 in. x 18 in. |

| Network Turning | 17 in. x 39 in. |

Looking for sales partner all around the world

Ace we are providing fully solution for precision components manufacture. We are looking for sales partner all around the world. We can also do part development for our client

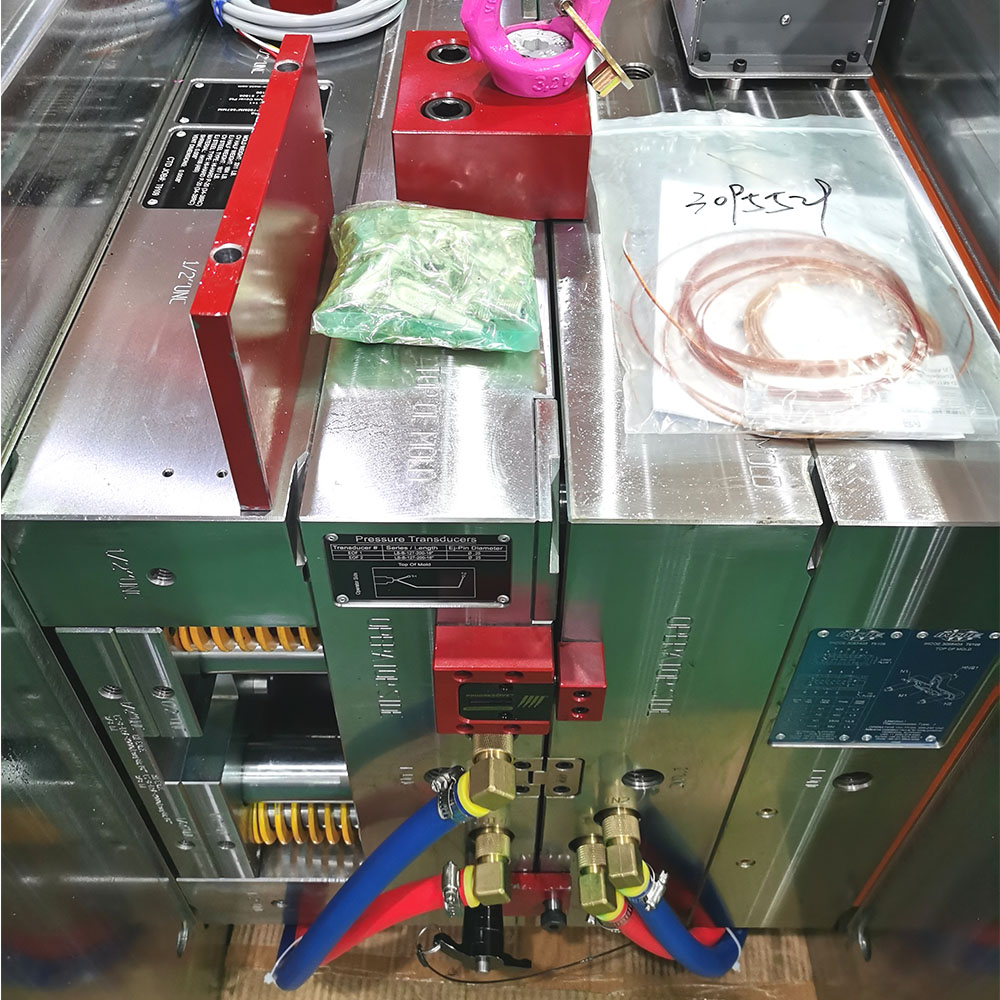

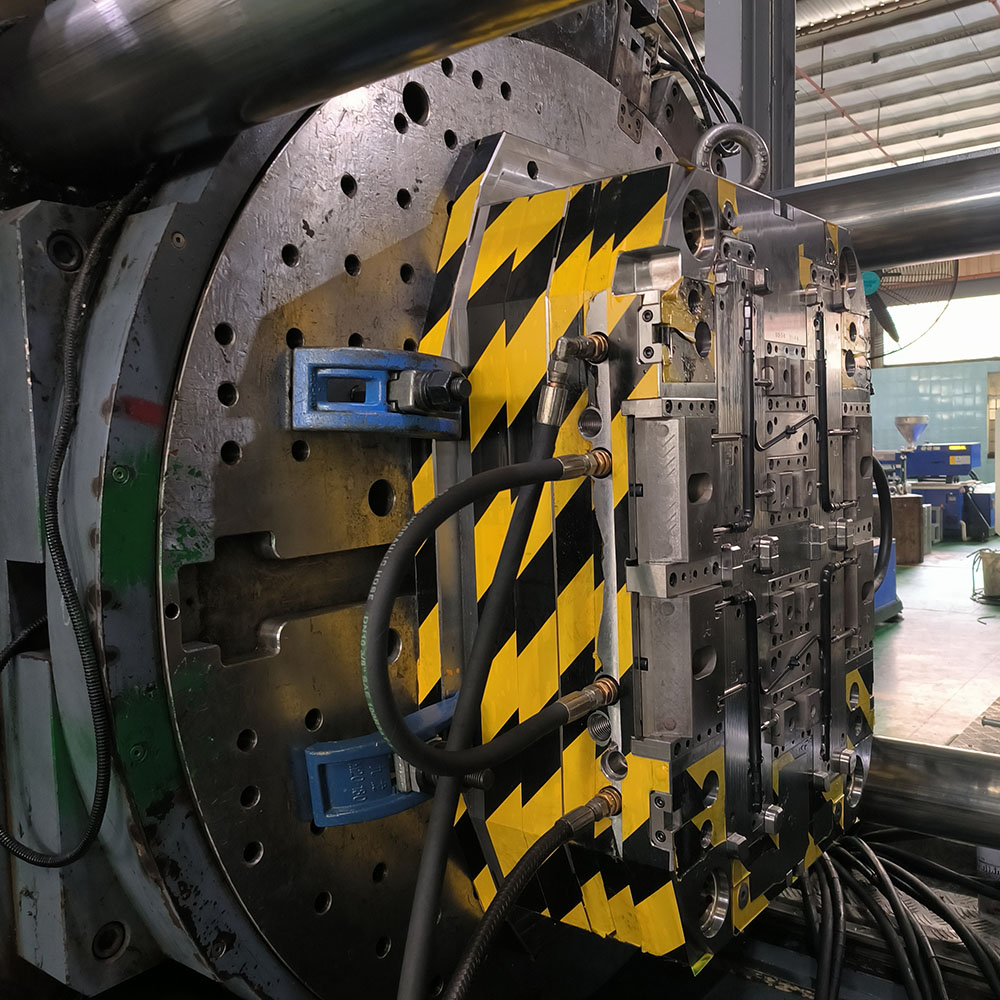

Injection Molding Capabilities

At Ace Our engineering department will have details study with customer product, and give our best suggestion for the part optimize, meanwhile our engineering department will according to customer request to choose the best and lower cost for the solution, make sure all part in good quality but also spend the lowest money for the project

Injection Mold Surface Finishes 2

We primarily offers SPI finishes for plastic injection molds. For VDI textures, specify your requirements when submitting your quote on our platform.

|

Mold Class |

Production Level |

Cycles |

Applications |

Tolerance |

Cost |

Lead Time |

|

Class 105 |

Very low |

Less than 500 cycles | Prototype testing |

± 0.02mm |

Inexpensive to produce a very limited number of product prototypes |

7-10 days |

|

Class 104 |

Low |

Less than 100K cycles | Good for limited-production parts with non-abrasive materials |

± 0.02mm |

Fall within low to moderate price ranges |

10-15 days |

|

Class 103 |

Medium

|

Less than 500K cycles | For low to medium-production parts | ± 0.02mm |

Fall within common price ranges |

10-15 days |

|

Class 102 |

Medium to high | Less than 1M | Good for parts with abrasive materials and/or tight tolerances | ± 0.02mm |

Fairly high price and made with materials of high quality |

10-15 days |

|

Class 101 |

Extremely high | Over 1M cycles | Extremely high production and fast cycle times | ± 0.02mm |

Highest price and made with only the highest quality materials |

10-18 days |

How Custom Injection Molding Works?

In the injection molding process, raw plastic materials are loaded into an injection molding machine, where they are melted. These melted plastics are then injected into a mold made of aluminum or steel. As the material cools, it solidifies into a production-grade thermoplastic part, which is then ejected for subsequent use or assembly.

Injection Molding Process At Ace-mold

Discover how Ace-mold manages your orders, starting from providing quotes, crafting high-quality injection molds, to producing production-grade plastic parts. Our experienced team and advanced machinery ensure each step is completed efficiently for on-time delivery

Components drawing confirmation

Components Rough machining

Components heat treatment

Components Optimize machining

Components final machining

Components dimension inspection

Our Injection Molding Services Cater to a Range of Industrial Applications

Ace-mold offers tailored injection molding solutions to meet the unique needs of various industries.

Automotive Industry

Aerospace Industry

Medical Device Industry

Robotics Industry

Reasons to Opt for Our Specialized Custom Injection Molding Services.

No MOQ

Our no minimum order policy facilitates the swift transition of plastic molded parts from design to production with quick turnaround times, catering to your on-demand injection molding requirements while also minimizing costs.

High Quality and Consistency

Possessing ISO certified factories and performing in-process inspections and dimensional verifications post-production, we ensure consistent quality in custom molded parts. This holds true even for complex shapes, as we maintain high precision throughout

Fast Turnaround

Our certified domestic factories and robust supply chain system enable us to expedite the product development cycle, allowing for the rapid production of plastic parts in as little as 2 weeks or even less.

Injection Molding Expertise

Work alongside our specialists, who have over 10 years of experience in injection molding, for expert advice on mold design, material selection, and finishing options, ensuring a seamless shift from prototyping to full-scale production.

Precision CNC components are high-precision parts manufactured using Computer Numerical Control (CNC) machines. These components are known for their accuracy, consistency, and ability to meet tight tolerances. CNC machining is commonly used in industries such as aerospace, automotive, medical, and electronics for producing intricate, durable parts