Plastic mold maker technology is an indispensable step in the product forming process. This is an industry that has a great influence on the economy and people's daily lives. The applications from it are extremely familiar and appear in almost every corner around us such as refrigerators, electrical panels, water pipes, etc.

Let’s find out more details with us in the article.

What is plastic injection molding technology?

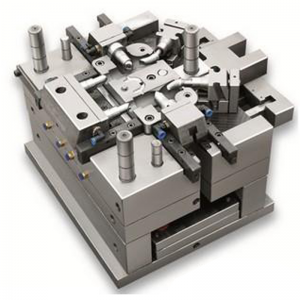

Plastic injection molding technology is an indispensable step to perfect a finished plastic product. It is applicable quite a lot in fields such as metal pressing, or glass. Moreover, it has an association with the specific name of plastic injection molding technology.

Plastic mold maker molding technology has many outstanding advantages over conventional plastic injection. Because it uses a mold tool accurate to one hundredth of a combined with a system of intelligent support devices to help create products with high accuracy, without the need for further refinement.

Besides, with its superiority, it also saves time and effort of workers and at the same time creates more and better quality products.

Function of plastic mold maker

Plastic injection molding technology is really a great step forward for Vietnam's mechanical industry in particular and the world in general.

This technology has opened up many open futures in creating more and more quality products with diverse designs. You must study the process of plastic mold maker technology.

Plastic injection molding methods and applications

Manual plastic injection molding or molding is the traditional method of shaping products that was born more than 40 years ago. It has some limitations as well. Moreover, it is still useful in production in small and medium establishments.

The process to create products from manual molding consists of 3 stages. First we need to heat the plastic material. Then, when the material has melted, it will be poured into the mold. It needs compressing into the desired shape. Take the mold to a cold place, let the mold cool quickly and the finished product will be stronger.

Plastic injection molding technology

Plastic mold maker process consists of 4 main steps, namely:

Step 1: Melt the ingredients. The raw materials are in the form of raw. Further, hard put into the hopper of the plastic injection machine. Here, the materials will be melted by a heating system that is evenly arranged around the screw of the plastic injection machine.

Step 2: The melted plastic will be injected into the mold. Plastic is injected into the mold with a micro nozzle to ensure that the mold is always closed.

Only then can a pressure difference be there to help the plastic in plastic mold maker. At this time, the mold will do the job of shaping the product.

Step 3: For the product to form faster and stronger, cooling the mold part is indispensable. On hot plastic injecting into the mold, it turns to a solid-state.

Step 4: Take the product out of the mold. When opening the two halves of the mold, the product ejection system will work. Further, the product will push out of the mold cavity. So, we will be able to remove the product. This is the final step in the plastic injection molding process.

The role of injection molding technology in life

Injection molding technology plays a huge role in people's lives because it brings a multitude of benefits. Products from injection molding technology often have more beautiful designs and designs than those produced by traditional methods.

This enhances the value and quality of products to consumers. The applications from plastic mold maker technology are extremely diverse and almost appear in our daily life such as household products such as plastic basins, plastic containers, plastic pipes to children's toys, shells.

INGREDIENTS FOR PLASTIC MOLDING – CONCRETE TRAY

- Firstly, plastic molding materials are made from hard plastic. Well suited for laboratories building test surfaces

- Secondly, plastic mold – the concrete tray is designed with a good steel bottom. It helps to increase the rigidity and certainty of the mold.

- Thirdly, it is easy to use for casting and dismantling the specimen by the 2-plate mold type. Moreover, pump straight into product.

HOW TO USE THE CONSTRUCTION TRAY TO MAKE CONSTRUCTION DETAILS?

- After creating a concrete mixture including cement, sand, stone and water, the worker will pour it into a plastic tray with the shape of the part.

- Then, let the concrete mixture solidify for about 2-3 hours, then take out the concrete product with the same shape as the concrete tray.

- Each day produces concrete parts using hundreds of concrete trays ofplastic mold maker. And each concrete detailing facility produces dozens of different types of concrete trays to create concrete details of different shapes and sizes.

TOP 4 golden criteria to create concrete tray plastic mold products

To create plastic molds in the form of concrete trays to give users the best experience about our products, there are extremely strict technical requirements.

- The first is a very large cooling criterion to avoid product surface shrinkage, reducing the time of 1 molding cycle.

- The second is that the surface of the mold cavity (the punch, the mortar) needs to be high to avoid sticking to the punch or the mortar during the molding process, to avoid the product being cracked.

- The third is a solid mold structure to withstand great pressure

- Fourth, the mold is guaranteed to run automatically.

Summary

Today on the market there are many types of plastic mold maker, with different shapes and qualities. Therefore, users need to consider carefully choosing reputable plastic molds that bring a good experience for use.