Plastic injection molding is a versatile and widely used manufacturing process that allows for the production of intricate and high-quality plastic components. ACE, a reputable plastic injection molding manufacturer, has been at the forefront of this industry, offering innovative solutions to clients worldwide.

In this blog, we'll provide you with a step-by-step guide to the plastic injection molding process, discuss how to choose the right injection molding components for your project and showcase real-world case studies to illustrate the broad applications of plastic injection molding.

Step-by-Step Guide to the Plastic Injection Molding Process:

Plastic injection molding is a precise and efficient method for producing plastic parts. It involves several essential steps:

1. Design and Prototyping: Plastic Injection Molding

The process begins with the design of the part and the creation of a prototype. Designers use CAD software to create a 3D model of the component, which is then used to generate a mold.

2. Mold Creation: Plastic Injection Molding

The mold, made from steel or aluminum, is precision machined to the exact specifications of the part. ACE's expertise in mold-making ensures that the mold is of the highest quality, guaranteeing consistent and accurate results.

3. Material Selection: Plastic Injection Molding

Choosing the right material is crucial. Different plastics have varying properties, such as strength, flexibility, and heat resistance. ACE can help you select the most suitable material for your project's requirements.

4. Injection Molding: Plastic Injection Molding

The actual injection molding process involves melting the plastic material and injecting it into the mold under high pressure. This step demands precision and control, as it affects the part's quality and consistency.

5. Cooling and Ejection: Plastic Injection Molding

After injection, the mold is cooled to solidify the plastic. Once sufficiently cooled, the part is ejected from the mold. ACE's advanced cooling systems ensure optimal part quality.

6. Quality Control: Plastic Injection Molding

Inspection and quality control measures are taken to ensure the parts meet the specified tolerances and quality standards. ACE is committed to delivering high-quality products.

How to Choose the Right Injection Molding Components for Your Project:

Selecting the right injection molding components is vital to the success of your project. ACE offers expertise in helping clients make the right choices:

1. Material Selection

As mentioned earlier, the choice of plastic material is a critical decision. ACE can provide guidance on material selection based on factors like strength, durability, and environmental compatibility.

2. Mold Design

ACE's experienced team can assist in optimizing mold design for your project. A well-designed mold is essential for achieving precision and efficiency in the molding process.

3. Production Volume

The quantity of parts you need will influence the choice of molding technology. ACE offers both low and high-volume production solutions to suit your specific needs.

4. Tolerances and Surface Finish

Consider the required tolerances and surface finish for your parts. ACE's machinery and expertise allow for tight tolerances and excellent surface finishes.

Case Studies: Real-World Applications of Plastic Injection Molding:

Plastic injection molding has a wide range of applications across various industries. Here are a few real-world examples to illustrate its versatility:

1. Automotive Industry: Plastic Injection Molding

Plastic injection molding is extensively used to produce components for the automotive sector, including dashboards, door panels, and engine parts. ACE has partnered with leading automotive companies to provide high-quality, durable components.

2. Medical Devices: Plastic Injection Molding

Precision is paramount in the medical industry. ACE has contributed to the production of medical devices, such as syringes, IV connectors, and surgical instruments, meeting stringent quality and safety standards.

3. Consumer Electronics: Plastic Injection Molding

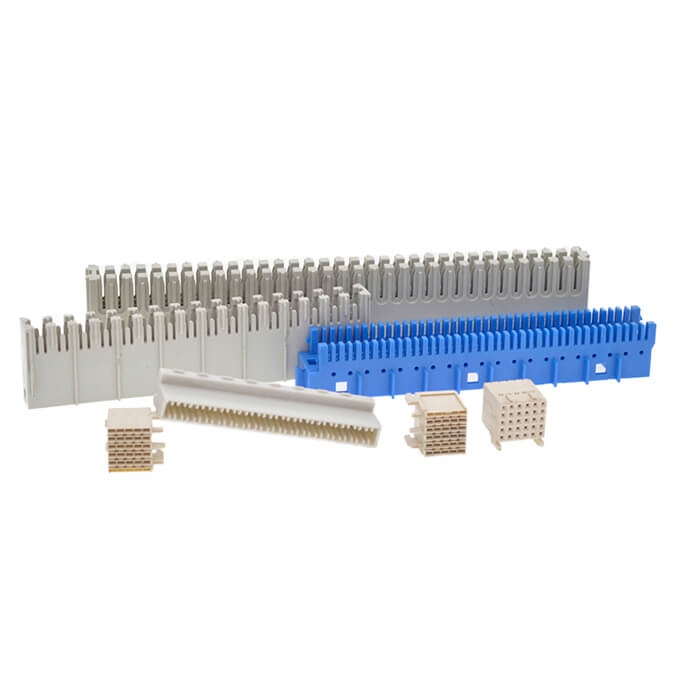

The production of electronic enclosures, connectors, and other components for devices like smartphones and tablets relies on injection molding. ACE's expertise ensures these components meet exacting specifications.

4. Packaging: Plastic Injection Molding

Plastic injection molding is vital in the packaging industry, where it is used to create containers, caps, and closures. ACE has worked with packaging companies to produce reliable and attractive packaging solutions.

Troubleshooting Common Issues in Plastic Injection Molding

1. Warpage*

Warpage occurs when the product cools unevenly, causing it to bend or warp. ACE's engineers address this issue by optimizing cooling techniques and ensuring even temperature distribution within the mold.

2. Flash*

Flash is excess plastic that escapes from the mold cavity, leaving thin, unwanted protrusions on the product. ACE's meticulous attention to detail during mold design and maintenance prevents flash, resulting in clean and polished products.

3. Sink Marks*

Sink marks are depressions on the surface of the product caused by uneven cooling. ACE minimizes this issue by fine-tuning cooling parameters and ensuring uniform cooling throughout the mold.

4. Short Shot*

A short shot happens when the mold is not completely filled with plastic material, leading to an incomplete product. ACE's precise injection and quality control procedures prevent short shots, ensuring every product meets specifications.

5. Weld Lines*

Weld lines occur when two flow fronts of plastic material meet and create a visible line on the product's surface. ACE's engineers carefully design molds and select materials to minimize the appearance of weld lines, resulting in visually appealing products.

ACE: Your Trusted Partner in Plastic Injection Molding

ACE, as a prominent plastic injection molding manufacturer, is committed to delivering high-quality plastic products through a meticulous and efficient process. With a focus on material selection, mold design, injection, cooling, ejection, and rigorous quality control, ACE ensures that each product meets the highest standards of quality and precision.

The team at ACE understands the common issues in plastic injection molding and is well-equipped to troubleshoot and prevent them, resulting in products that not only meet but exceed customer expectations.

Conclusion:

Plastic injection molding is a versatile and precise manufacturing process, with applications across numerous industries. ACE, a renowned manufacturer, offers comprehensive solutions to clients seeking high-quality plastic components. With a deep understanding of the plastic injection molding process, they guide clients in material selection, mold design, and production volume choices, ensuring the success of various projects. Through case studies, we have seen how this technology impacts diverse industries, from automotive to medical devices and consumer electronics, highlighting its importance in the modern world. For reliable and high-quality plastic injection molding, ACE stands as a trusted partner for all your needs.