Why Using Injection Mould in Your Manufacturing Process Is Beneficial?

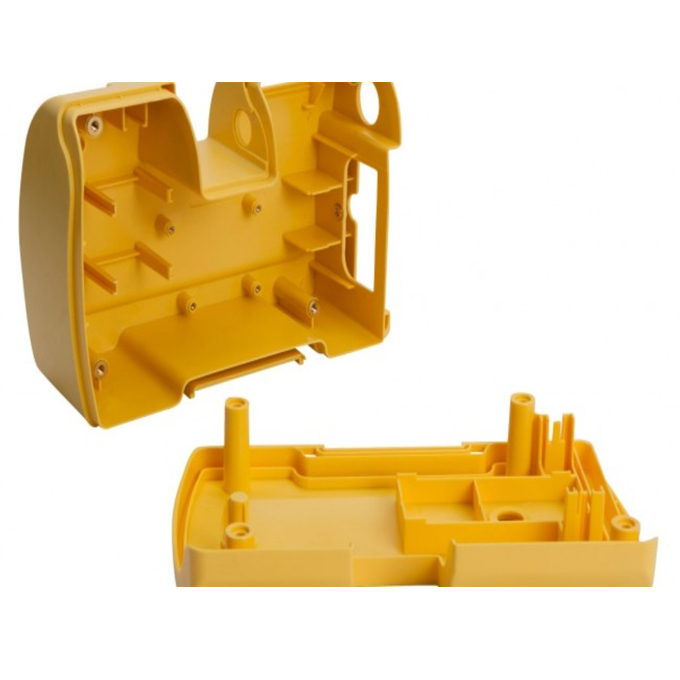

What does Injection Mold mean? Why Choose ACE? The Method of Injection Moulding: The Beneficial Effects of Injection Molding in the manufacturing process: Injection moulding is a manufacturing method where melted materials are injected into a mould to create a range of parts and goods, typically plastic pellets. Many advantages of this approach include the

ACE is the top Efficient and Cost-Effective Plastic Injection Molding Manufacturer

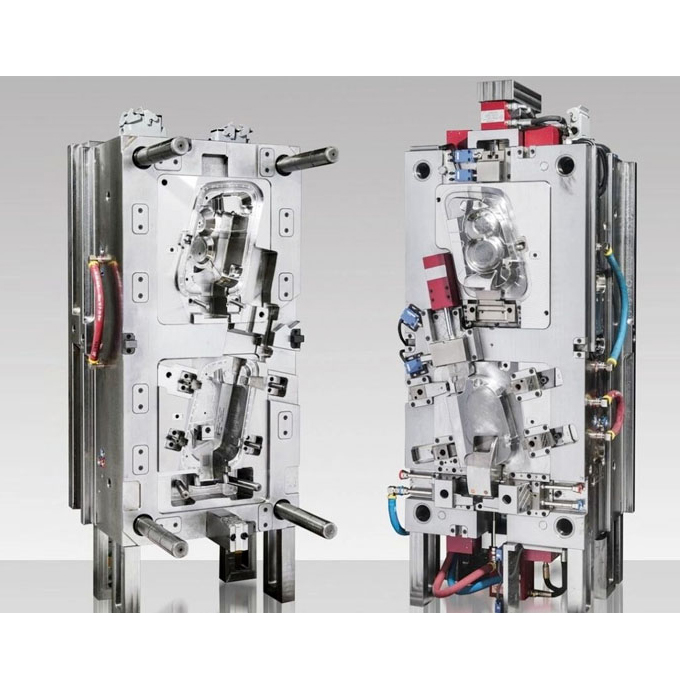

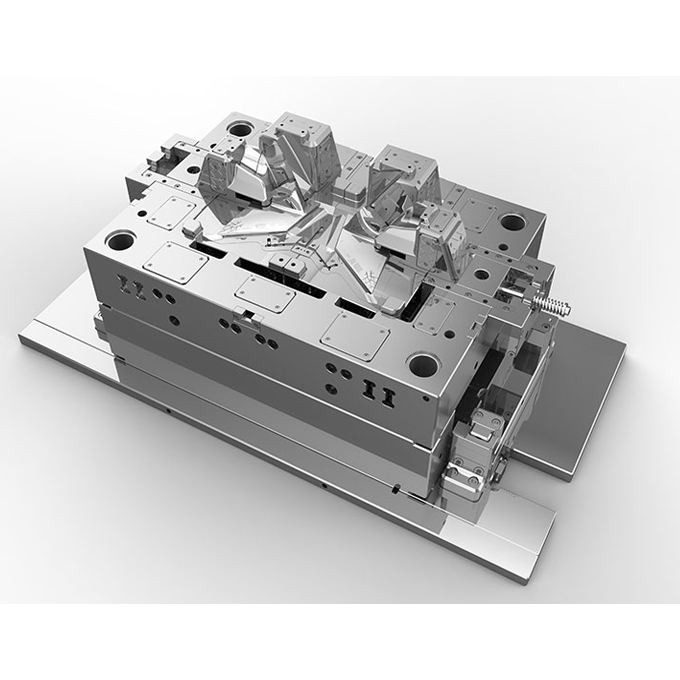

What exactly is plastic injection molding? The procedure of plastic injection molding is used to make objects with intricate features and forms. This procedure injects molten plastic into a mould cavity, allowing it to cool and solidify into the desired shape. The method is perfect for making objects with exquisite features, complicated geometries, and precise tolerances.

Clean Room Injection Molding: Maintaining a Quality-Producing Environment

What does the term clean room injection molding mean? Injection moulding in a clean room is a manufacturing procedure in a sterile setting. This procedure requires pouring molten plastic into a mould cavity at high pressure to manufacture a final product. The clean room is intended to remove contaminants like dust, germs, and other pollutants

How can foaming mould enhance the performance of your product?

What is meant by Foaming mould? A form of plastic injection moulding technique known as “foaming mould” enables the manufacture of lighter and stronger items. A foam-like structure is produced by injecting gas into the molten plastic during the injection process. This can have a number of advantages, such as increased strength, decreased weight, and