In the world of manufacturing and product development, molding companies play a crucial role. These companies are often the unsung heroes behind many of the products we use daily, from automotive parts and consumer electronics to medical devices and packaging materials. One such prominent player in the molding industry is ACE Molding. In this blog, we will delve into the significance of molding companies like ACE, explore the latest technological advancements in the field, understand their commitment to regulatory compliance, and highlight the benefits of partnering with global molding companies.

What Are Molding Companies?

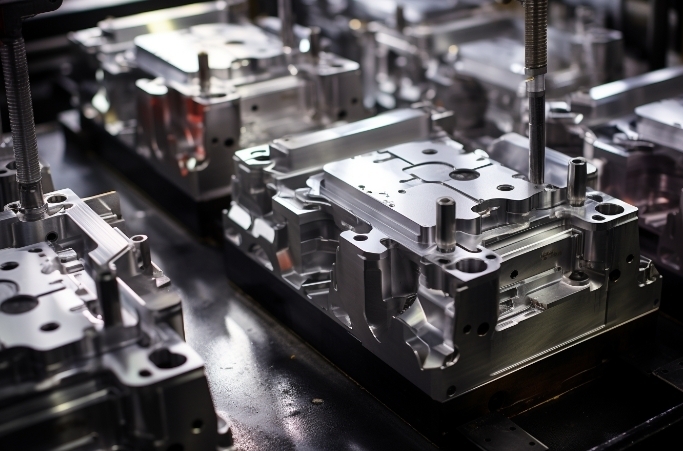

Molding companies, such as ACE, are specialized manufacturers that utilize various molding techniques to shape raw materials into finished products. The primary goal of these companies is to create precise and consistent components or products, often in large quantities. There are several molding processes, including injection molding, blow molding, compression molding, and rotational molding, each suitable for different applications. These processes are the cornerstone of product development for industries ranging from automotive and aerospace to healthcare and consumer goods.

The Latest Technological Advancements in Molding Companies

Molding companies have evolved significantly over the years, embracing advanced technologies to enhance precision, efficiency, and speed. One of the most notable advancements in the field is the adoption of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These software tools enable engineers and designers to create intricate molds with unprecedented accuracy and complexity.

Furthermore, the integration of automation and robotics has revolutionized the production processes within molding companies. Automated systems not only reduce labor costs but also ensure consistent quality by minimizing human error. ACE Molding, for instance, utilizes state-of-the-art robotic systems to streamline production and maintain the highest standards of quality.

In addition to CAD/CAM and automation, 3D printing has made a significant impact on the molding industry. Prototyping and mold development have become faster and more cost-effective through 3D printing, allowing companies like ACE to offer rapid prototyping services to their clients. This technology enables quick iterations and modifications during the product development phase, ultimately saving time and resources.

Ensuring Regulatory Compliance

Molding companies must adhere to strict regulatory standards and certifications, depending on the industries they serve. This is particularly critical in sectors like healthcare and aerospace, where product safety and quality are paramount. ACE Molding, like many other reputable molding companies, takes regulatory compliance seriously.

They invest in advanced quality control systems and employ skilled quality assurance professionals to ensure that every product meets or exceeds the required standards. Additionally, they maintain robust documentation and traceability processes to provide full transparency and accountability in their operations. This commitment to compliance is crucial for building trust with clients and end-users alike.

Why Should You Choose Molding Companies for Custom Parts?

Customization is often a key requirement in product development, and molding companies excel in meeting this demand. ACE and similar molding companies specialize in producing custom parts with precision and consistency. They can create parts tailored to specific designs and specifications, whether it's a unique automotive component or a specialized medical device.

The advantage of choosing molding companies for custom parts lies in their expertise in molding techniques such as injection molding, which allows for the production of intricate and complex parts with minimal waste. This not only ensures that your custom parts meet your exact requirements but also helps in cost-effective production.

Why Do Industries Rely on Molding Companies for Prototyping?

Prototyping is a crucial stage in product development, allowing designers and engineers to test and refine their concepts before mass production. Molding companies like ACE play a pivotal role in this process. They can produce prototypes quickly and cost-effectively using techniques such as rapid injection molding.

By leveraging the capabilities of molding companies for prototyping, industries can accelerate the development cycle and make informed decisions about design changes and improvements. This not only saves time but also reduces the risk of costly errors later in the production phase.

What Makes Molding Companies Essential in Modern Supply Chains?

Efficient supply chains are the lifeblood of modern manufacturing. Molding companies are essential components of these supply chains because they can provide just-in-time production and reduce the need for large inventories of components or products. ACE and similar companies offer reliable and consistent production capabilities, ensuring that the supply chain remains streamlined and responsive to market demands.

Molding companies are often capable of managing inventory, warehousing, and shipping, further simplifying the logistics for businesses. This allows manufacturers to focus on their core competencies while leaving the intricacies of component production and supply chain management to experts like ACE.

Can Molding Companies Help You Create Complex Geometric Shapes?

Creating components with complex geometric shapes can be challenging, but molding companies have the expertise and technology to overcome these challenges effectively. ACE, for instance, utilizes advanced molding techniques and specialized tooling to produce parts with intricate geometries.

One of the standout molding processes for creating complex shapes is injection molding. It allows for the production of parts with varying thicknesses, undercuts, and intricate features that would be difficult or impossible to achieve with traditional manufacturing methods. This capability is particularly valuable in industries like aerospace and automotive, where lightweight and high-strength components with complex shapes are in demand.

Benefits of Partnering with Global Molding Companies

Partnering with global molding companies like ACE offers numerous advantages for businesses looking to develop new products or components. Here are some key benefits:

1. Expertise and Experience: Global molding companies have a wealth of experience in various industries and applications. They can provide valuable insights and recommendations to optimize product design and production processes.

2. Cost-Efficiency: Due to their economies of scale and access to advanced technologies, global molding companies can often offer competitive pricing without compromising on quality.

3. Quality Assurance: These companies have established quality control processes to ensure that each product meets the highest standards. This reduces the risk of defects and recalls, saving both time and money.

4. Global Reach: Partnering with a global molding company allows businesses to tap into a worldwide network of suppliers and distributors, facilitating market expansion and growth.

5. Quick Turnaround: Global molding companies often have the capacity and resources to handle large production runs efficiently. This can significantly reduce lead times and accelerate time-to-market for new products.

6. Innovation and R&D: Many global molding companies invest in research and development to stay at the forefront of technological advancements. This can lead to innovative solutions and improved product performance.

Conclusion

In conclusion, molding companies like ACE are indeed the cornerstone of product development across various industries. Their adoption of cutting-edge technologies, commitment to regulatory compliance, and global reach make them indispensable partners for businesses seeking to bring their ideas to life. Whether you're in the automotive, medical, or consumer goods industry, partnering with a global molding company can be a strategic move that paves the way for success in a competitive market.