The time it takes to complete an injection moulding process can vary depending on several factors such as the size and complexity of the part, the material used, and the number of parts being produced.

The cycle time, which is the time it takes for the machine to inject the material, cool and eject the part, can range from a few seconds for small, simple parts to several minutes for larger, more complex parts.

Additionally, the overall production time also includes the time it takes to set up the machine, load the material, and perform quality checks on the finished parts.

On average, the production time for injection moulding can range from several hours for small batch production to several days or even weeks for larger runs.

Injection moulding is an important industrial process used to make a variety of products. From plastic parts to medical equipment and custom-made toys, there are many different applications for this process. But with so many variables in play, it’s tough to answer the question “how long does injection moulding take?”.

In this blog post, we’ll uncover the surprising answers to this question and provide some tips on how to reduce injection moulding time. So, let’s dive in and answer the age-old question: how long does injection moulding take?

Introduction to Injection Moulding

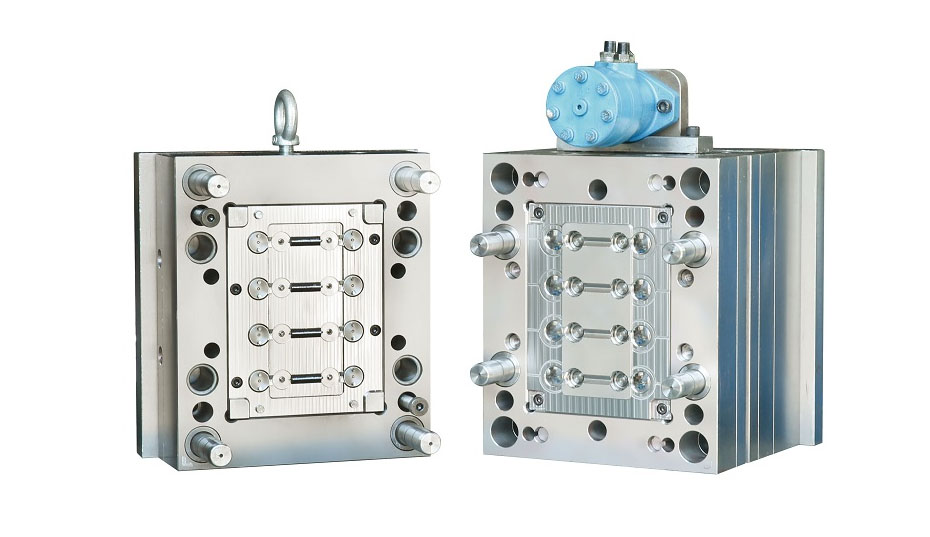

Injection moulding is a process used to manufacture plastic parts and components. It works by injecting molten plastic into a mould, which is then cooled and hardened. The result is a precise and accurate part that can be used for a variety of applications.

Injection moulding is popular because it’s a fast and efficient way to produce plastic parts and components. But the exact speed of production can vary depending on a number of factors. So, let’s take a look at what affects the time it takes to complete an injection moulding job.

What Factors Affect How Long Injection Moulding Takes?

There are several factors that can affect the duration of an injection moulding job. These include:

- Design complexity

- Material choice

- Machine parameters

- Condition of the mould

- Post-moulding processes

Let’s take a closer look at each of these factors and see how they can impact the injection moulding time.

Design Complexity

The complexity of the design can have a big impact on the injection moulding time. The more intricate the design, the longer it will take to produce the part or component. This is because more complex designs require more detailed moulds and often require more precise machine settings.

It’s also important to consider the size of the part or component. Larger parts can take significantly longer to produce, as they require more material, longer cooling times and higher pressure settings.

Material Choice

The type of material used in injection moulding can also affect the time it takes to complete the job. Different materials have different melting and cooling points, which can affect the speed of production.

For example, materials such as ABS and polypropylene are relatively fast to process, as they have low melting points. However, more difficult materials such as nylon and polycarbonate can take longer to process.

Machine Parameters

The settings of the injection moulding machine can also affect the injection moulding time. Different machines have different capabilities and settings, which can influence the speed of production.

For example, the injection pressure and temperature settings can affect the speed of production. If the settings are too high, the injection process can take longer. On the other hand, if the settings are too low, the part or component can be under-injected, resulting in defects and a longer turnaround time.

Condition of the Mould

The condition of the mould is another important factor to consider. If the mould is in poor condition, it can lead to defects, which can cause delays in production.

It’s also important to consider the age of the mould. Older moulds are more prone to defects and can take longer to produce parts and components.

Post-Moulding Processes

In addition to the injection moulding process itself, there are other post-moulding processes that can affect the time it takes to complete a job. For example, some parts may require secondary operations such as painting, assembly, and packaging.

These post-moulding processes can take a significant amount of time, so it’s important to factor them into the injection moulding time.

Tips for Reducing Injection Moulding Time

There are several steps you can take to reduce the time it takes to complete an injection moulding job. Here are some tips to help you speed up the injection moulding process:

- Simplify the design – simpler designs can be produced faster and with fewer errors.

- Choose the right material – select materials that have low melting and cooling points to speed up the process.

- Adjust machine parameters – set the injection pressure and temperature settings to the recommended levels to ensure a fast and accurate production.

- Maintain your mould – keep your mould in good condition to ensure a smooth and efficient production process.

- Streamline post-moulding processes – ensure that post-moulding processes such as painting, assembly, and packaging are streamlined to reduce delays.

By taking these steps, you can reduce the time it takes to complete an injection moulding job and get your product to market faster.

Conclusion

As you can see, the duration of an injection moulding job can vary greatly depending on a number of factors. From design complexity to post-moulding processes, there are many variables that can affect the injection moulding time.

By taking the steps outlined in this blog post, you can reduce the time it takes to complete an injection moulding job and get your product to market faster.

So, the answer to the question “how long does injection moulding take?” is that it depends on several factors. But with the right preparation and careful consideration of the variables, you can reduce injection moulding time and get your product to market faster.