Manufacturing success lies in the pursuit of maximum efficiency. When striving towards that goal, die makers are a pivotal part of creating the tools for cost-effective production. To learn more about this process, ACE Die Maker provides a helpful look into what's needed for seamless and productive collaboration. This blog will share their expertise, giving valuable tips to cut costs while still enjoying streamlined production.

As we appreciate the seamless products that surround us, let's not forget to acknowledge the tireless work of ACE, the master die maker, whose dedication to excellence continues to transform industries and touch our lives in remarkable ways. From automotive and home appliances to electronics, die makers like ACE are the unsung heroes behind the scenes, ensuring that our everyday products are produced with unmatched accuracy and efficiency.

1. Understanding the Role of ACE Die Maker

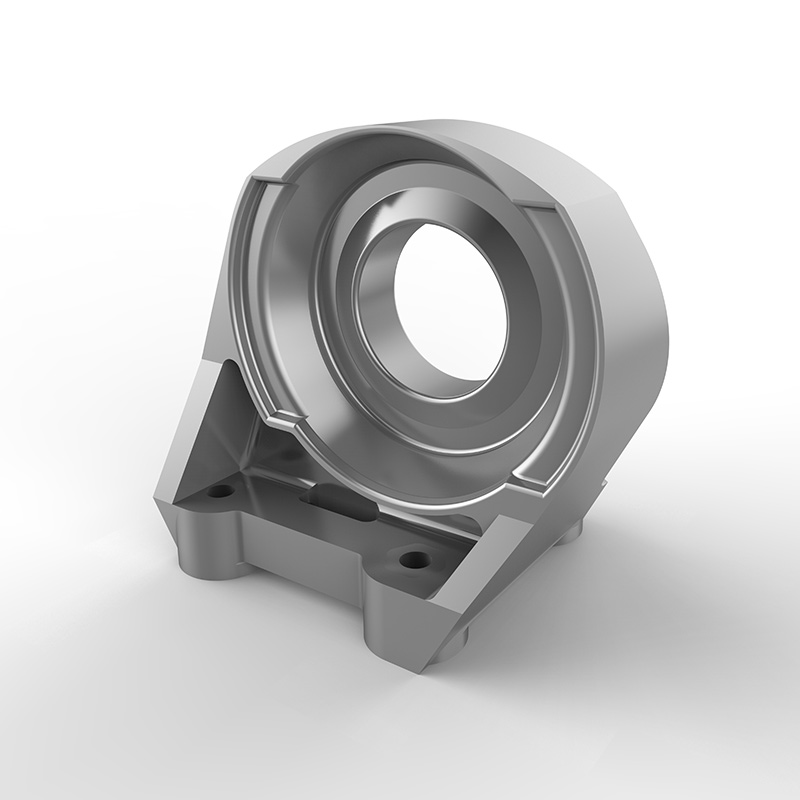

ACE Die Maker is a reputable and experienced professional responsible for designing and manufacturing dies, molds, and other tooling equipment used in various manufacturing processes. They are skilled in transforming raw materials into complex shapes with high precision, ultimately impacting the final product's quality and cost.

2. Early Involvement Yields Optimal Results

To achieve maximum efficiency, it is essential to involve ACE Die Maker from the initial stages of product development. Collaborating closely with the die maker during the design phase ensures that the tooling requirements are well-defined, avoiding potential issues and reducing the need for costly adjustments later in the process.

3. Material Selection and Tooling Techniques

The choice of materials and tooling techniques significantly impacts the manufacturing process's efficiency and cost. ACE Die Maker possesses extensive knowledge of various materials and can advise on the most suitable options for specific projects. Choosing the right materials and techniques improves tool life, reduces maintenance costs, and enhances overall productivity.

4. Regular Maintenance for Prolonged Die Life

Regular maintenance is essential to ensure the longevity and optimal performance of the dies. ACE Die Maker can provide valuable maintenance schedules and tips to keep the tooling equipment in prime condition. Proper maintenance not only extends the life of the dies but also prevents unexpected downtime, which could be costly for the manufacturing process.

5. Collaboration for Continuous Improvement

An open and collaborative relationship with ACE Die Maker fosters an environment of continuous improvement. Regular communication and feedback help identify potential bottlenecks or areas of improvement in the manufacturing process. By working together, both parties can innovate and implement cost-saving solutions, driving overall efficiency.

6. Embracing Technological Advancements

ACE Die Maker keeps abreast of the latest technological advancements in the field. Integrating innovative techniques, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), can significantly enhance the efficiency of the tooling process. Embracing technology optimizes precision, reduces lead times, and maximizes productivity.

7. Quality Assurance and Inspection

ACE Die Maker takes pride in their workmanship and ensures the tooling equipment's quality. Establishing a rigorous quality assurance and inspection process guarantees that the dies meet the required specifications. This not only reduces the risk of defects in the final product but also minimizes costly rework and scrap.

Unveiling the World of Die Making: Meet ACE, the Master Die Maker

I. The Art of Die Making: Merging Precision and Creativity

Die-making is a highly specialized craft that blends technical expertise with artistic finesse. At its core, a die is a metal tool used to shape, cut, or form materials into specific shapes or designs. From simple patterns to complex structures, the die maker must carefully plan and engineer the die to deliver seamless results. ACE Die Maker exemplifies the perfect blend of precision and creativity, possessing an innate ability to transform raw materials into intricate dies that drive modern manufacturing.

II. ACE's Journey: Nurturing Skills and Expertise

ACE's journey into the world of die-making is a testament to dedication and continuous learning. Starting as an apprentice, ACE honed the fundamental skills of die-making under the guidance of experienced masters. The learning process involved studying various materials, mastering CNC machines, and understanding the intricacies of tool and die design. With every challenge, ACE developed problem-solving skills and the ability to visualize the end product, making them true experts in their craft.

III. Automotive Industry: Shaping the Future on Wheels

One of the primary domains in which ACE excels is the automotive industry. The demand for precision dies in automotive manufacturing is non-negotiable, given the complexity and safety requirements of modern vehicles. ACE collaborates closely with automobile manufacturers, employing cutting-edge technologies and innovative materials to create dies that produce flawless car parts. From body panels to engine components, ACE's expertise ensures that the automotive industry keeps moving forward.

IV. Home Appliances: Elevating Everyday Comfort

In the realm of home appliances, ACE's proficiency finds its way into shaping the tools we rely on every day. Whether it's crafting dies for kitchen appliances, vacuum cleaners, or washing machines, ACE's attention to detail and dedication to perfection makes them the go-to die maker for many home appliance manufacturers. The quality of their dies directly impacts the efficiency and reliability of these appliances, ultimately elevating our daily comfort and convenience.

V. Electronics: Pioneering Innovation and Miniaturization

The electronics industry is marked by constant innovation and the pursuit of miniaturization. As devices become smaller and more sophisticated, the need for intricate dies becomes paramount. ACE embraces the challenge, of working hand-in-hand with electronics manufacturers to create dies that enable the production of cutting-edge components and circuits. Through their contribution, ACE empowers the electronics industry to push boundaries and redefine what's possible.

Conclusion:

Working with ACE Die Maker is a strategic step towards achieving efficient and cost-effective manufacturing processes. By involving them early in the product development phase, embracing technological advancements, and maintaining open communication, businesses can streamline production, reduce expenses, and maintain a competitive edge in the market. Efficient manufacturing, driven by a strong collaboration with skilled die makers, paves the way for successful and sustainable growth in the manufacturing industry.