Injection molding temperature recommendations

According to China mold maker, the casting temperature T l is the temperature of the molten polymer. It extrudes from the heating cylinder into the mold. The casting temperature determines by the temperature set in the zones of the heating cylinder.

The temperature in the zones of the heating cylinder is set taking into account the selected casting temperature. And it also assesses the ratio of the screw stroke. Moreover, it happens during injection H to the screw diameter D.

There are two options for the temperature distribution profile:

- Increasing temperature profile from hopper to nozzle at H <1.5D

- Similarly, Horizontal profile at H> 1.5D

About the temperature in the heating cylinder of the TPA

The area of the cylinder under the feed throat is cooled. Otherwise material in this area can stick to the auger and hopper neck. The flow area reduces due to adhered material and the plasticizing performance decreases.

With an increase in the temperature T viscosity of the material decreases and the filling of the mold becomes easier for China mold maker. The length of flow of material into the L shape increases. To improve the casting technology, a uniform temperature of the portion of the melt prepared for injection is important.

About adjusting the temperature of injection China mold maker

The solidification time of the casting and the sprue depends on the value of the melt temperature. Similarly, it means the duration of holding under pressure and the stability of the weight and dimensions of the product.

It is not necessary to increase the casting temperature above the manufacturer's recommended temperature. Hence, this will lead to the destruction of the plastic, a change in its properties and color. If, at the upper values of the working temperature range of casting, the China mold maker is still not filled, it is advisable to consider.

Possibility of changing the design of the China mold maker

- increase in inlet sizes

- sprue expansion

- Similarly, increase in the thickness of the thinned sections of the product

With a decrease in the temperature T l, the casting productivity increases slightly. Also, but it is not necessary to lower the temperature T l below the recommended one. The waviness of the casting surface, a trace from a stream of melt, sinking, underfilling may occur.

Requirements for the quality of the product

China mold maker maintains the temperature of the casting within the operating ranges according to the product. Similarly, the parameters of the plasticizing process and the prevailing requirements for the quality of the product are also important. The specific value of largely depends on the value of the ratio of the volume of the casting of the product.

The lower the value of this ratio, the more dangerous it is to increase the temperature of the melt. This can lead to degradation of the thermoplastic.

The quality of China mold maker products.

The design and correctness of the choice of the injection molding machine (injection molding machine), its technical condition

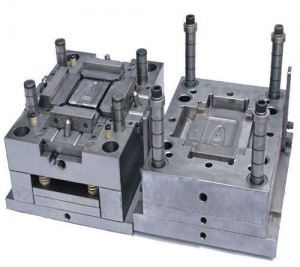

Mold design

Technological parameters of the potential process of plastic injection molding and preparation of polymer material for casting

The correct choice of polymer material and its quality

Initially, it is necessary to clarify the correctness of the choice of the injection molding machine. The technical condition of the injection China mold maker machine is very important. Also, Technicians should pay attention to the condition of the auger valve, the performance of the electric heaters, the heating cylinder thermocouples, and the cooling efficiency of the bunker area.

For machines with a lever system of the clamping mechanism, it is necessary to check the correct setting of the clamping unit.

Operation of a plastic injection mold

Correct regulation of the temperature of both halves of the mold, control of the surface temperature of the China mold maker cavity and the uniformity of its distribution are important.

Raw materials and parameters of casting

When analyzing polymer raw materials, it is necessary to consider the compliance of the material properties with the standards specified in the TU, the presence of a passport for the raw material, the state of the granulate packaging, its initial moisture content.

When using secondary waste, it is important to monitor the quality of storage, sorting, crushing and drying of waste, correct quantitative addition of them to the primary material.

It is necessary to strictly observe the technological modes

When casting products, it is necessary to strictly observe the technological modes, parameters and recommendations that are given in the operating instructions for the China mold maker. Namely:

Do not change the design of the gating system for the sake of eliminating one weld line, as other "incomprehensible" casting problems will arise.

Self-made decisions of installers

Self-made decisions of installers are detrimental to the tooling - turn off the thermostat, seal up the evaporation channels, plug the sprue inlet or fill notches (delays) on the punch

Systematic control of the mode of protection of the mold from breakage, protection of structural parts from jamming, overheating, corrosion is required.

Access to the adjustment of the injection molding machine must be coded

The stationary plate of the injection molding machine rests on the frame elements that have a large contact surface with it. Also, compared to the four-point support in knee-lever injection molding machines, this results in a much larger support surface and, as a result, significantly less deflection.

Thanks to this design feature, the China mold maker has improved support. Furthermore, the movable plate is connected to the hydraulic cylinder by means of a flex link, which ensures an even distribution of the clamping force.

Advantages of machines with a column less clamping unit system:

- Minimum assembly time (especially for large molds), efficient robot access.

- High precision plate parallelism.

- Also, Optimal conditions for retrofitting injection China mold makermachines with an extensive network of peripheral modules.

Conclusion China mold maker

Support for the movable plate. By design, robust frame elements are the ideal foundation for precision linear bearings. These bearings are good simultaneously to guide and support the plates and to take the load of the weight of the China mold maker.

Moreover, Precision plate guide minimizes tool wear. Linear bearings of high accuracy class come by minimal frictional losses and enable a very sensitive form protection function.