What is a three-plate mould?

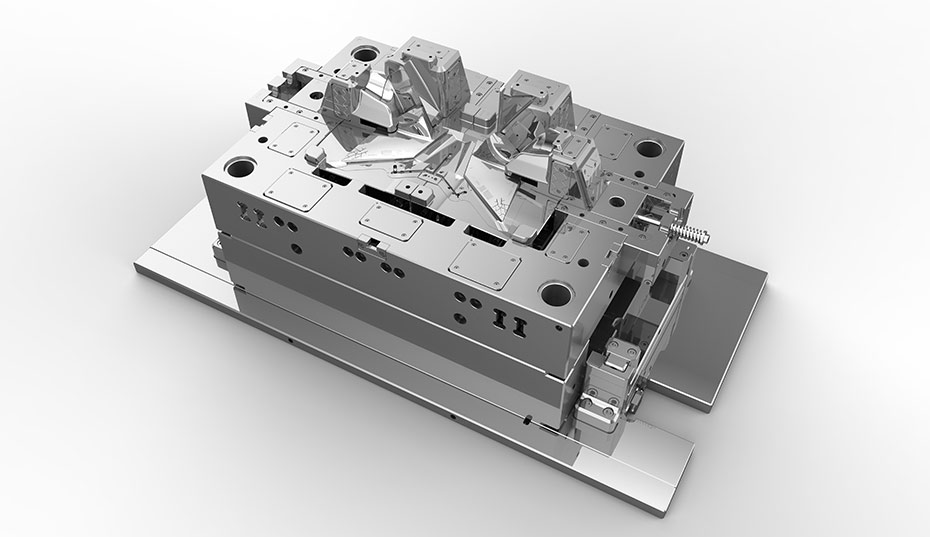

- A 3 plate mold, sometimes called a three-plate mould, is a particular kind of injection molding tool utilized in producing plastic components. Because it is made up of three plates or sections—a runner plate, a cavity plate, and a stripper plate—it is known as a three-plate mould.

- The component of the mould that makes a path for the flowing plastic melt into the cavity plate is called the runner plate. The cavity plate predetermines the ultimate product's shape, and the molten plastic is injected into the cavity to assume that shape. The final item is removed from the mould using the stripper plate when it has cooled and set.

- With a two-plate mould, producing intricate plastic components with undercuts or interior details would be difficult or impossible. This is why the three-plate mould is frequently utilized. The additional plate provides a separate route for the plastic to flow into the mould and a separate mechanism for ejecting the final product, which gives the molding process greater flexibility. A three-plate mould can, however, be more difficult to make and more expensive to maintain than a two-plate mould.

The Making of Molds is Made Simple by a 3 Plate Mold:

- A 3 plate mold is a type of injection mould that makes creating molds easier by enabling manufacturing more intricate elements with fewer mould pieces. Three plates, the cavity plate, the core plate, and the runner plate, make up this kind of mould and divide it into three portions. While the imprint of the component to be moulded is on the cavity plate, the impression of the part's interior features is on the core plate. Channels are made using the runner plate, which feeds the molten plastic into the cavity.

- The 3 plate mold divides into three portions, making reaching the cavity and core plates for upkeep and repair simpler and quicker. Additionally, because the ejection pins may be inserted into the runner plate rather than the cavity or core plates, the chance of the moulded item being damaged during ejection is decreased. Due to its ability to produce more complicated parts using fewer mould pieces, 3-plate molds can save material waste and costs. Consequently, production lead times may be shortened, and part costs may be reduced.

What Should You Know About a 3 plate mould?

The cavity plate, the core plate, and the runner plate are the three major plates that make up a 3-plate mould, a form of an injection mould employed in producing plastic parts. What you need to know about each dish is as follows:

- The portion of the mould known as the cavity plate gives the finished product its form and surface polish. It has a hollow area or chamber inside which molten plastic is poured to create the part. The interior characteristics of the product, like holes and undercuts, are formed by the core plate.

- It has a core or solid projection that fits into the cavity plate to give the product its final shape. The runner plate regulates how much-molten plastic flows into the cavity. It has passages transporting plastic to the cavity and core plates from the injection molding machine.

The positive benefits of 3 Plate Mold:

This plate molds are useful for plastic injection molding for several reasons. The following are some major benefits:

- Greater component Design freedom:

Compared to conventional two-plate molds, three-plate molds provide greater component design freedom. It is possible to produce components with more complicated geometries and more sophisticated gating setups when a separate runner plate is used.

- Enhanced Quality:

Adding a second runner plate can enhance the component quality in three-plate moulds. This is possible because the gating system may be adjusted to lessen the likelihood of flaws such as weld lines, jetting, and air traps.

- Higher Production Rates:

The molds can create components with many cavities, resulting in higher production rates and lower part prices. For high-volume manufacturing runs, this is very helpful.

- Reduced Cycle Time:

Compared to two-plate molds, three-plate molds may also produce parts more quickly since the ejection system can be made to work separately from the gating system. This can lead to shorter cycle durations since the component can be ejected before the gating system completely cools.

- Improved Mould Maintenance:

The three-plate molds may be simpler to maintain since the separate runner plate may be removed for upkeep without affecting the cavity and core plates. This can lessen downtime and enhance mould performance in general.

Why is ACE the best supplier of 3 plate mold?

- We respond to requests quickly and begin working as soon as we get your email, and quotes are given out within 24 hours.

- Our own design and development team is here.

- We have a robust quality control system to guarantee the highest quality products.

- We can beat our rivals' prices and offer competitive pricing.

- We provide samples quickly, and each sample has undergone quality control.

- We offer OEM/ODM services to various clients, communicate openly with our customers during shipping, and deliver things on schedule.

- We are proud that at least 96% of our customers have been with us from the beginning.

Conclusion:

One kind of mould that is frequently used in the plastic injection molding procedure is the 3 plate mold. It combines the two-plate mould with the three-plate mould, two distinct varieties. The fabrication of plastic components may be done with more precision and flexibility thanks to this combination. We can foresee possible quality issues and risks associated with tool manufacture at an early stage and work with the client to optimize the design to remove those risks prior to the commencement of mould production. Meanwhile, ACE provides a significant, reliable partner in the region that supplies equipment weighing between 50 and 2000 tonnes.