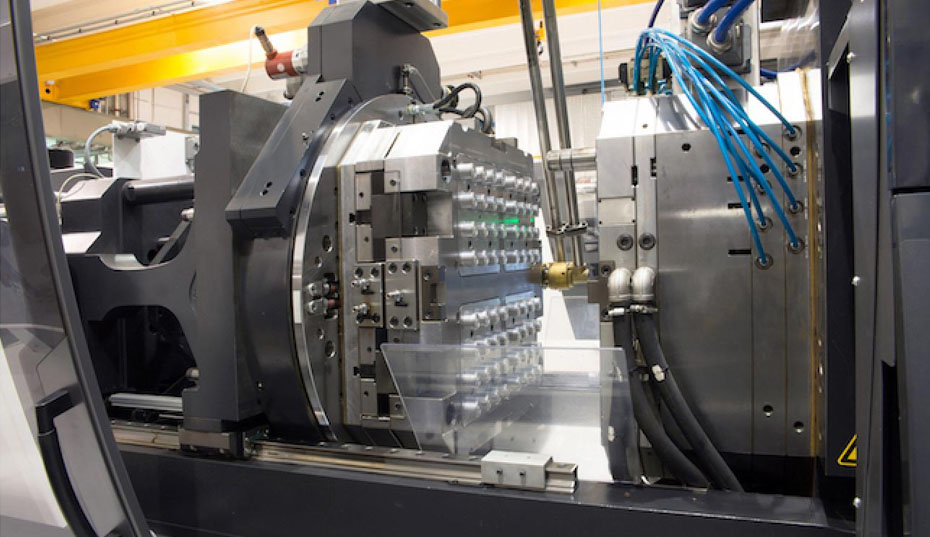

Plastic injection molding is a manufacturing process used to produce a variety of plastic parts, products, and components. In this process, melted plastic is injected into a mold cavity under high pressure, where it cools and solidifies to form the desired shape.

Used plastic injection molding refers to the purchase and use of previously owned injection molding machines or equipment to produce plastic parts. This can be a cost-effective option for companies looking to expand their manufacturing capabilities or start a new production line without investing in new equipment.

When purchasing used plastic injection molding equipment, it is important to ensure that the equipment is in good working condition and that it meets your specific production requirements. This may involve inspecting the equipment, testing it, and verifying its history and maintenance records.

In addition to the cost savings, purchasing used plastic injection molding equipment can also offer other benefits, such as faster delivery times, reduced lead times, and increased flexibility in terms of customization and production runs.

However, it is important to note that used equipment may have some limitations and may not be suitable for all types of production. It is important to carefully evaluate your needs and requirements and choose the equipment that best fits your needs and budget.

What is Used Plastic Injection Molding?

Used plastic injection molding is a process in which plastic pellets are heated and injected into a mold. The mold is then cooled and the plastic is injected out of the mold. This process is typically used for mass-producing plastic parts for various industries, such as automotive, electronics, and medical.

Used plastic injection molding is a cost-effective process that can be used to produce high-quality parts. It also allows for precise shapes and sizes that are difficult to achieve with other manufacturing processes.

The Benefits of Used Plastic Injection Molding

Used plastic injection molding has many benefits over other manufacturing processes. It is cost-effective, fast, and can produce complex and precise shapes. Additionally, it can be used to produce large quantities of parts in a short amount of time.

The process also produces parts that are lightweight and durable. This makes them ideal for a wide range of applications, from automotive components to medical devices.

The History of Used Plastic Injection Molding

The history of used plastic injection molding dates back to the late 19th century. The process was first developed by John Wesley Hyatt, who used it to create billiard balls. Since then, the process has become increasingly popular and is now used in a wide range of industries.

Today, used plastic injection molding is one of the most popular manufacturing processes in the world. It is estimated that over 3 billion parts are produced using this process every year.

The Process of Used Plastic Injection Molding

The process of used plastic injection molding involves several steps. First, a plastic resin is melted and injected into a mold. The mold is then cooled and the plastic is injected out of the mold. The part is then trimmed, inspected, and packaged.

The process of used plastic injection molding is relatively simple and efficient. It can be used to produce parts of any shape and size with a high degree of accuracy.

Different Types of Used Plastic Injection Molding

There are several different types of used plastic injection molding. These include single-shot, two-shot, and multi-shot molding. Each type has its own advantages and disadvantages.

Single-shot molding is the most common type of used plastic injection molding. It involves injecting a single shot of molten plastic into a mold. This type of molding is a cost-effective solution for producing parts with simple shapes and sizes.

Two-shot molding is used when two different colors or materials are needed for the part. This type of molding requires two different molds, one for each material. Two-shot molding is ideal for producing parts with intricate details or parts that need to be made from two different materials.

Multi-shot molding is a more advanced form of plastic injection molding. It involves injecting multiple shots of molten plastic into a single mold. This type of molding is ideal for producing complex parts with intricate details.

Used Plastic Injection Molding Materials

The materials used in used plastic injection molding vary depending on the application. Common materials include polypropylene, polyethylene, polycarbonate, and ABS. Each material has different properties, such as strength, stiffness, heat resistance, and chemical resistance, that make it suitable for different applications.

It is important to choose the right material for the application. The wrong material can lead to poor quality parts or parts that are not suitable for the application.

The Advantages of Using Used Plastic Injection Molding

Used plastic injection molding offers a number of advantages over other manufacturing processes. It is cost-effective, fast, and can produce parts of any shape and size with a high degree of accuracy. Additionally, it allows for precision and repeatability, which is important for mass-producing parts.

Used plastic injection molding is also ideal for producing complex parts with intricate details. This makes it ideal for a wide range of applications, from automotive components to medical devices.

The Challenges of Using Used Plastic Injection Molding

Used plastic injection molding is not without its challenges. One of the biggest challenges is finding the right material for the application. The wrong material can lead to poor quality parts or parts that are not suitable for the application.

Another challenge is finding the right molding process. Different types of molding processes require different types of molds and materials, so it is important to choose the right one for the application.

The Future of Used Plastic Injection Molding

The future of used plastic injection molding looks bright. As more industries discover the benefits of this process, it will become increasingly popular. Additionally, new materials and technologies are being developed that will make this process even more efficient and cost-effective.

In the future, used plastic injection molding may become even more widely used. This will open up new possibilities, such as the mass production of medical devices or the development of new materials that are stronger, lighter, and more durable.

Conclusion

Used plastic injection molding is a cost-effective and efficient manufacturing process that can be used to produce high-quality parts. It has several advantages over other manufacturing processes, such as cost-effectiveness, speed, and precision. Additionally, it can be used to produce parts of any shape and size with a high degree of accuracy.

Used plastic injection molding is a versatile process that is used in a wide range of industries. As the process continues to evolve and become more efficient, it will open up new possibilities for manufacturers. With used plastic injection molding, the possibilities are endless.