Engineering Plastic Injection Moulding

Engineering plastic injection moulding is a process used to create a wide variety of parts, from small components to large, complex shapes. It’s an efficient and cost-effective way to produce parts for a variety of applications. his process involves a heated plastic material that is injected into a mould, which then hardens and is then ejected from the mould.

ACE offers turnkey plastic solutions, from innovative concept design to reality. ACE can meet our customers' most difficult demands by combining international state-of-the-art equipment with traditional tool-making knowledge. With our collective experience, the ACE team designers and toolmakers are constantly striving to refine and perfect our skills. Our superior performance is based on the successful completion of every step. "Right at the first time".

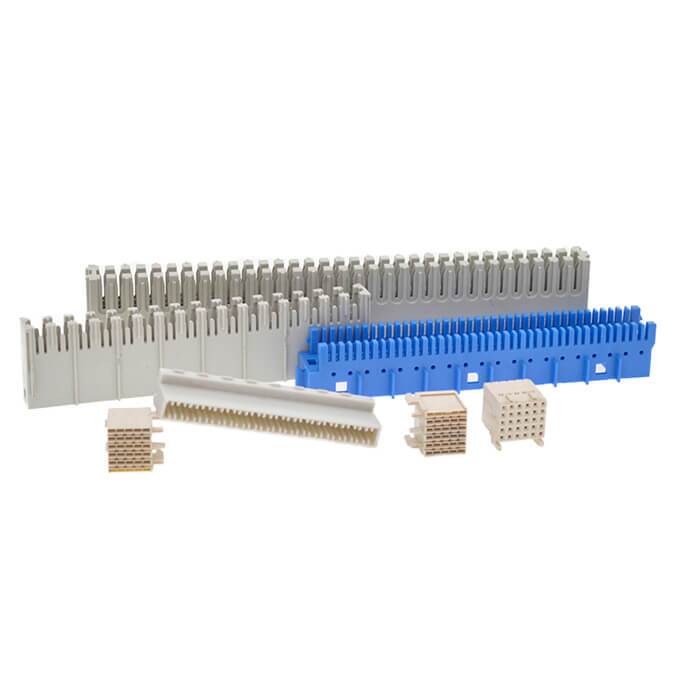

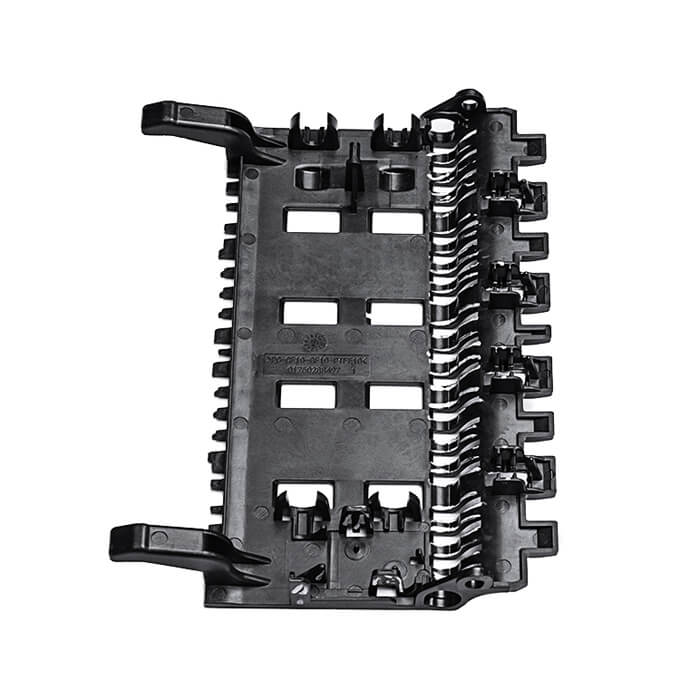

ACE made a lot of the engineering parts with:

- Plastic processing with Medium and large processing windows

- For all thermoplastics including Filler and reinforcing materials

Benefits of Engineering Plastic Injection Moulding

Engineering plastic injection moulding has become a popular choice for manufacturers due to its cost-effectiveness and efficiency. This method of manufacturing offers a variety of advantages, such as improved design flexibility, increased production speed, and reduced scrap rates. These materials are widely used in automotive, aerospace, medical, and other industries due to their excellent properties.

Durability: Engineering plastic injection moulding is a versatile and durable manufacturing process for creating plastic parts for a variety of industries. The process is customizable, allowing for intricate details and complex designs to be created, and is also highly durable, making it an ideal choice for parts that require longevity and repeated use.

Design flexibility: Engineering plastic injection moulding is a process where molten plastic material is injected into a cavity, which is then cooled and ejected as a finished product. This process is used for producing a variety of plastic products, such as automotive parts, consumer electronics, medical devices, and industrial components.

Efficiency: Injection molding is a process of forming plastic parts by injecting molten thermoplastic material into a mold cavity. The injection molding process is complex and involves various parameters that must be optimized to obtain good quality parts.

Why Choose ACE Group

1. We have a highly experienced in-house design and development team. We are very comfortable and skilled in dealing with our international clients.

2. We provide OEM/ODM services to all types of customers and have professional customer support and project management teams on hand 24 hours a day, seven days a week.

3. We have a strict quality control system in place to ensure that our products are of the highest quality, that we provide the best service, and that our prices are competitive.

4. Quality inspection samples are always available and can be quickly delivered to you.

5. Design ability: create designs that adhere to customer specifications.

6. We deliver goods on time and work transparently with customers.

| Brand Name | ACE |

| Model Number | ACEENG0010 |

| Mould Material | NAK20, S136, P20, 718H, 738H, 45#, etc |

| Mould Shaping | Plastic injection moulding |

| OEM/ODM | Acceptable |

| Mould Base | LKM, HASCO, DME, etc |

| Mould Cavity | Single or Multi |

| Tolerance | +/-0.01mm |

| Package | Standard or as your request |

| Standard Delivery | 40 days or 5 weeks |