A Guide to Product research and development

Product research and development is the most important and one of the initial stages of any product life cycle. Similarly, in the injection molding industry, product research and development carry similar significance. Research and development are two sides of the same coin. Each plays an important role.

Research is essentially the initial stage of a life cycle. In this step, the researchers come up with findings that can help in developing the product error-free. Moreover, this is not the only thing related to the product; it also involves the conception of the main product.

You May Also Read: Importance of the Plastic Electronic Part Manufacture

On the other hand, product development entails the complete process of the design, creation, and marketing of the product. It is not necessary for a product to go be new for the research and development team to come into action. Product research and development can take place for existing products too. This can happen for the betterment of the existing product too.

The role of Product research and Development in Injection Molding Industry

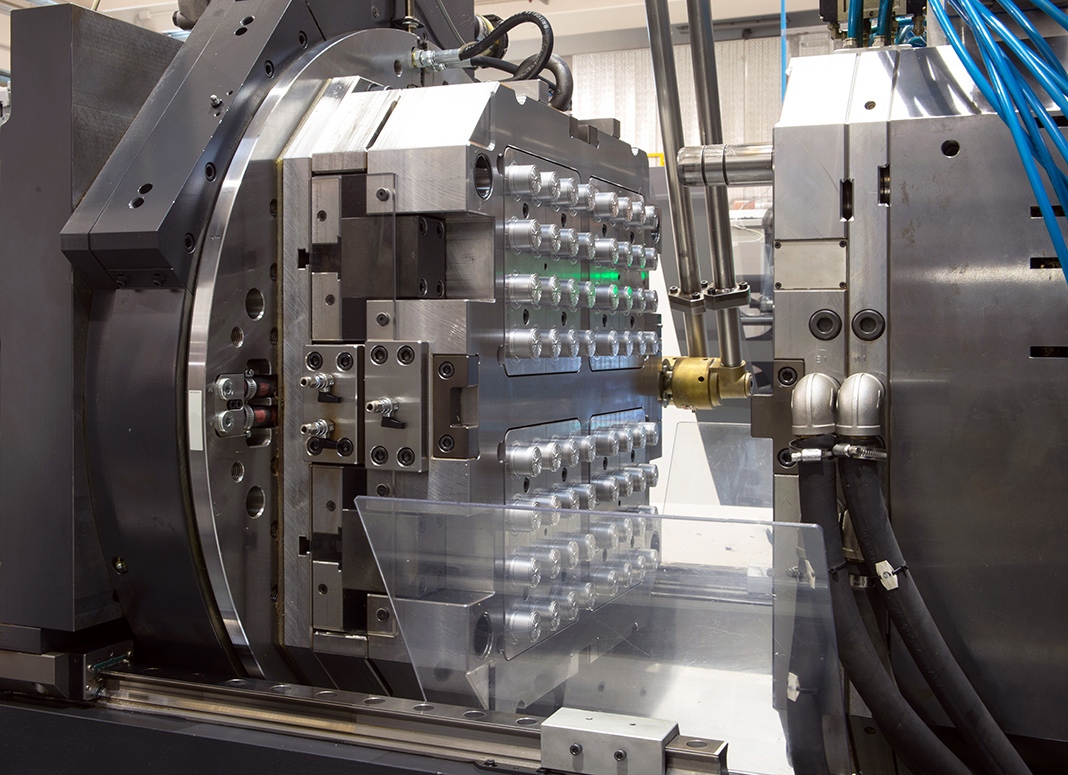

Significantly, product research and development play a major role in the Injection molding industry too. Like any other industry, without research and development, the existing products cannot flourish. This department makes sure that the product quality keeps on improving and more features keep on adding the original design.

The following are some proposed and implemented product research and development in the injection molding industry. They suggest improvements that can lead to better quality and optimized production.

Functional Nanostructures on Injection Molded Plastic

This research shows that with using Nano-technology, the injection molding industry can make plastic parts that are economical in nature but with efficient and attractive features. This incorporates very standard procedures of injection molding.

Smart Plastic Functionalization by Nano-imprint and Injection Molding

In this technique, injection molding makes use of sub-micrometer surface arrangements such that they make a way for constructing nifty and functionalized plastic parts. They also make use of Nano-imprinting to make bendable molds to ease the transfer of patterns on design molding.

Plastic Pulleys by Injection Molding

This research was mainly developed to reduce the manufacturing costs that accumulate in the automobile industry. Plastic pulleys are the variably famous manufactured products for injection molding. This has proven to be a strong power-driven step. Plus its wear and tear resistance is quite high. This helps in increasing the strength of the welded parts. The newly established material construction is very cost-effective thus it automatically reduces the manufacturing cost.

Design and Checking Analysis of Injection Molding of a Plastic Cup

In the following research, specialized injection molds that show the physical features of a plastic cup establish. The parameters involved in this type of injection molding consist of stripping off, dragging, and holding capability. This helped a lot in creating a uniform mold for the production of such kinds of parts. This is a very operational and concrete method for mass production. It became a problem solver for cases with similar product development.

Importance of Injection Molding Prototype Production

The few of the above research and developments injection molding techniques show that improvements are taking place by leaps and bounds. Without a proper team for this purpose, no kind of improvement can occur. And the need for improvement is essential for any kind of industry and the same goes for injection molding.

The first step in any kind of product development must lay on a solid basis. Creating an initial prototype model for this is the part that comes under the research team. It helps them in making a solid base for further changes that may improve the design.

One of the essential issues confronting any individual who needs to get an item to the market needs to make sure that the intended item production must go sufficiently planned, performs accordingly, and is stylishly satisfying. This rule applies regardless of the industry whether they are creators, businessmen, or set up organizations. There are numerous approaches to solve this issue.

Creating Model Prototype

Creating a model prototype is a basic step to the pathway that leads to making the final product. The significance and the benefits of various kinds of prototyping help in making observations for designers and businessmen so that they can make further improvements.

Above all else, when creating a model signifies the fact that in making it the cost is much less than the actual large-scale production itself. In simple words, this is important before major production happens. It is definitely easy for the manufacturers to make correctional modifications in the prototype rather than making changes in the mass-produced design. This can cost a lot of time and money which is not good from an investor’s point of view.

This is where the research team helps in stopping this disaster. The researchers need to work diligently in order to prevent and accommodate disaster management. The prototype not only helps in product development but also detecting improvements in the products.

The Ideal Solution for Injection Molded Prototypes

After the prototype development and its finalization, the development of the product starts. Sometimes the development process ends up making millions of copies of the same product. Due to the quantity of production, the developers make sure that the design has passed all the protocols and obstacles that the product must pass. The design must pass through rigorous testing, it should be visually pleasing and the functionality must follow the specifications to the dot.

We cannot emphasize enough the importance of a research and development team. The right way to go about this is to produce the product in thousands rather than millions. Then it must go through the rigorous testing phase of the injection molded parts. For this phase, specialized injection molding tools conduct a research well into the future.

This can substantially reduce the risk factor and eliminate the downfall of investors. This thoroughness of the execution of plans makes the success rate of the product to increase many folds. It is a foolproof plan if executed religiously.

Alternatives to Injection Molded Prototypes

In spite of the fact that the formation of infusion models is favorable but there are much more affordable models too. These prototypes can create and iterate using 3D printing. This is also known as rapid prototyping. Another way is by using CNC (Computer Numerical Control) machining. These devices are becoming precious pearls in the modern world. They do too have a few limitations that need to be addressed in order for it to work effectively.

Testing by using these tools is important. The test conduction shows that research on real-time injection molding prototypes produces results that are going to help in results that are helpful in judging expected results.

You May Also Read: China Plastic Molder: Importance of Plastic Injection Molding

Conclusion

Ultimately, we can observe that the research and development team can devise and utilize different testing techniques. They need to test the design, stability, functionality, and physicality of the injection-moulded product. This is the need for useful analysis techniques and their implementation. For mass production to succeed these are the few considerations that need thoughtful regressive planning.

The research and development team stays accountable for producing the model prototype. For an investor to invest in the right type of injection moulded product they need tangible proof of the product and what is better than the prototype of the product itself. This is going to be a long-term stable relationship between the research and development team and the investors.

For More Information, Contact us Today!