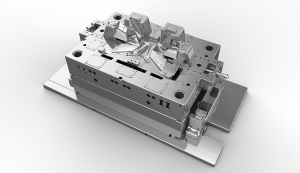

Firstly, plastic injection molding in USA is an industrial production process in which a plastic material melts and inject under high pressure into a close mold, which is open after the product has solidify.

How does injection molding work?

Materials such as synthetic resins (plastics) heat and melt, and then sent to the mold where they are cool to assume the design shape.

Plastic injection molding in USA of thermoplastic materials is the most widespread technology in the transformation of plastic materials. Furthermore, we produce pieces of different shapes and sizes and the weight varying from a few grams to several kilos in a constant manner.

How does an injection molding machine work?

Injection: a program-control speed applies to the screw, with freedom to use the available hydraulic pressure. The screw, moving rapidly forward, like a piston, forces the molten material, through the nozzle, into the cavity of the mold.

Plastic injection molding in USA is a collective name for various heterogeneous industrial production processes that have in common the fact of using a permanent form call a mold as a tool. Eventually, transformation of low section pieces is simple

What is injection molding for?

This is compression molding guide, from prototyping to mass production. Occasionally, compression molding is a versatile manufacturing process. It is common by small and large manufacturing companies to create a wide variety of parts. This from aircraft components to bottle spouts.

Compression plastic injection molding in USA is very flexible and makes it easier to incorporate inserts. It also contains textile ones into the product. Moreover, it allows to process elastomers with superior characteristics but difficult to process by injection. It is certainly, more suitable for small and medium-size productions.

How does plastic injection molding work?

The liquid metal injects into the mold and thanks to the pressure (up to 100 MPa) it fills all the cavities. The result of obtaining a more compact and uniform structure than those for casting.

How can molding take place?

Plastic injection molding in USA is best injection all over the world. After that, it is an industrial process in which the plastic material is heat. After that, it comes under high pressure into a close mold. It will then open when the material has solidified.

In a nutshell, thermoforming is a technique of hot molding of various plastic materials. As well as, sheets putting them under vacuum or under pressure. As well as, take specific but desire shapes, to accommodate certain objects. With the same profile develop with the system that it is being treat.

How is plastic extrusion done?

To begin, in the extrusion process, the plastic injection molding in USA in the form of small granules. Firstly, comes together by heating at specific temperatures. They are given a specific shape and finally, they are subject to a cooling-consolidation process.

What is blow molding for?

Initially, blow molding (or blow molding) is a production process common to obtain hollow plastic or glass products (for example bottles or flacons).

The technique consists in bringing a thin sheet of plastic material to an adequate temperature and then making it adhere around a particular using the vacuum created with a vacuum cleaner type (excellent canister vacuum cleaner).

Suction on rubber molding presses. The inverter allows for a fully automatic continuous adjustment of the motor revolutions according to the system requirements. It take the same time limiting the consumption of electricity and thus allowing considerable savings.

What are the processes of polymers?

To be transform into an article plastic injection molding in USA thermoplastic polymers require fluidization, forming and cooling. Gradually, these steps can be performed in different ways in the various processes. Extrusion: ... Extrusion (consists of a motor that turns a screw inside an externally heated cylinder.

How does a thermoformed work?

It is a process that requires a sheet of malleable and soft plastic to be heat and then applied to a mold. Eventually, sheet adheres to the mold thanks to the vacuum. The plastic mold, once it has cool and solidify, can be detach from the mold.

What is achieved with rotational plastic injection molding?

The process plastic injection molding in USA can be common to create bodies with simple shapes. Subsequently, it more complex shapes (furnishing accessories or automotive components) with walls of variable thickness between 2 and 15 millimeters.

What is achieved with thermoforming?

Lastly, thermoforming also allows for the molding of undercuts or the incorporation of metal details such as threads. The reinforcement plates that will allow the object to be firmly attach or screw to other totally metal components.

Forming is an operation that changes materials in a controlled way, forcing them to assume the desired shape or appearance. The most common forming techniques are bending.

What is mechanical blowing common for?

Plastic injection molding in USA can be common to make bottles or objects with complicate shapes. Eventually, it involves putting a glowing piece of dough into a mold and then blowing the piece of dough into it. The dough will swell like a balloon and will adhere to the mold, taking the desire shape.

New glass forming technique, create in the mid-1st century BC. Blowing is the expansion of a portion of molten glass into which a small amount of air is introduce. This allows for the production of blown glass with uniform thickness.

How does the extrusion process take place?

Process description: Extrusion essentially consists in forcing by compression the material, in the pasty state, to pass through a shape ("matrix" or "die") which reproduces the external shape of the piece to obtain.

In geology, term common to indicate non-plastic plastic injection molding in USA rock masses that emerge due to corrugation phenomena. Periodically, it between formations that is generally easily deformable.

To get best injection molding products, you need to hire China top injection molding company. You can order bulk and small series order.