A pet preform injection moulding machine is a type of machine used to produce PET preforms, which are small plastic parts used to create PET bottles. PET (Polyethylene Terephthalate) is a type of thermoplastic polymer that is widely used in the packaging industry due to its lightweight, strength, and durability.

In this article, we will discuss the various aspects of a pet perform injection moulding machine, including its components, working principle, advantages, and applications.

Components of a Pet Preform Injection Moulding Machine:

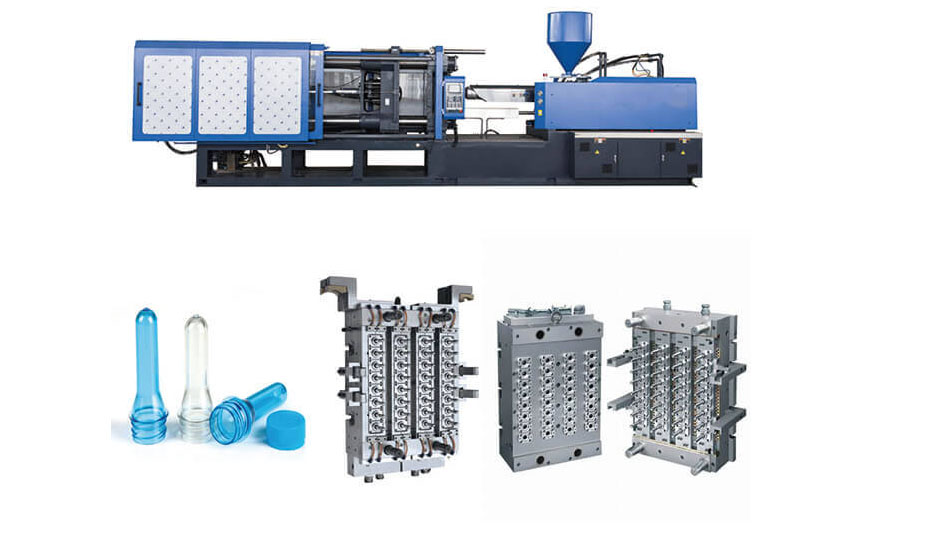

A pet perform injection moulding machine consists of several components, including:

- Injection Unit: This unit is responsible for melting the PET resin and injecting it into the mould cavity.

- Clamping Unit: This unit holds the mould in place and applies the required pressure to ensure that the preform is formed properly.

- Control Panel: This panel contains various controls that allow the operator to adjust the machine's parameters such as temperature, pressure, and speed.

- Mould: This component is used to shape the PET resin into the desired perform shape.

Working Principle of a Pet Preform Injection Moulding Machine:

The working principle of a pet perform injection moulding machine is relatively simple. The machine starts by melting the PET resin in the injection unit. Once the resin is melted, it is injected into the mould cavity using a screw or plunger.

The injection process is controlled by the machine's control panel, which regulates the temperature, pressure, and speed of the injection process. Once the resin has been injected into the mould, it is cooled and solidified, and the mould is opened, and the preform is removed.

Advantages of a Pet Preform Injection Moulding Machine:

- High Production Rates: Pet preform injection moulding machines can produce preforms at a high rate, resulting in increased production efficiency.

- Precision and Consistency: These machines can produce preforms with a high level of precision and consistency, ensuring that each preform meets the required specifications.

- Reduced Material Waste: Pet preform injection moulding machines can reduce material waste since they use only the required amount of resin to produce each preform.

- Energy Efficiency: These machines are energy-efficient since they use only the required amount of energy to heat the resin and inject it into the mould cavity.

Applications of a Pet Preform Injection Moulding Machine:

Pet preform injection moulding machines are widely used in the packaging industry to produce PET bottles of various shapes and sizes. Some of the applications of these machines include:

- Beverage Bottles: PET bottles are commonly used to package beverages such as water, soda, and juices.

- Food Containers: PET bottles are used to package food items such as ketchup, mustard, and salad dressings.

- Personal Care Products: PET bottles are used to package personal care products such as shampoo, conditioner, and body wash.

- Pharmaceuticals: PET bottles are used to package pharmaceutical products such as cough syrups, liquid antibiotics, and other medications.

Conclusion:

Pet preform injection moulding machines are essential machines used in the packaging industry to produce PET bottles. These machines are efficient, precise, and consistent, resulting in high-quality preforms. The use of these machines has revolutionized the packaging industry, making it possible to produce PET bottles of various shapes and sizes. With the increasing demand for PET bottles, the use of pet preform injection moulding machines is likely to increase in the future.