Get the Best Custom Precision Injection Molds for Your Business

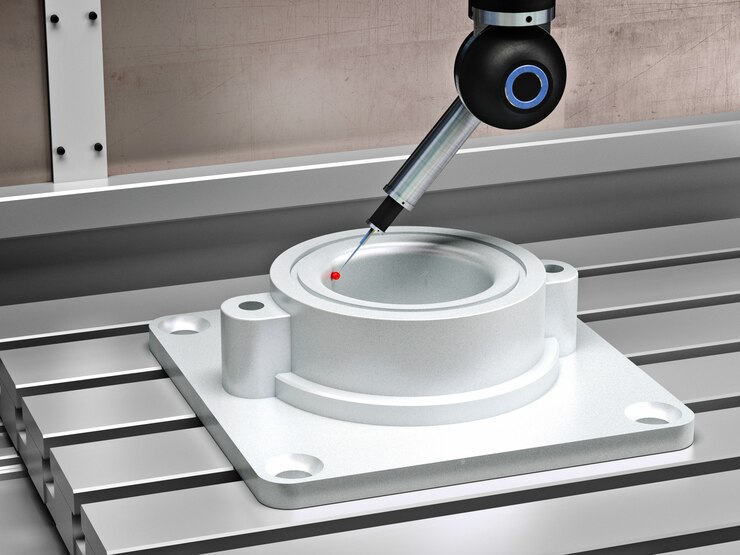

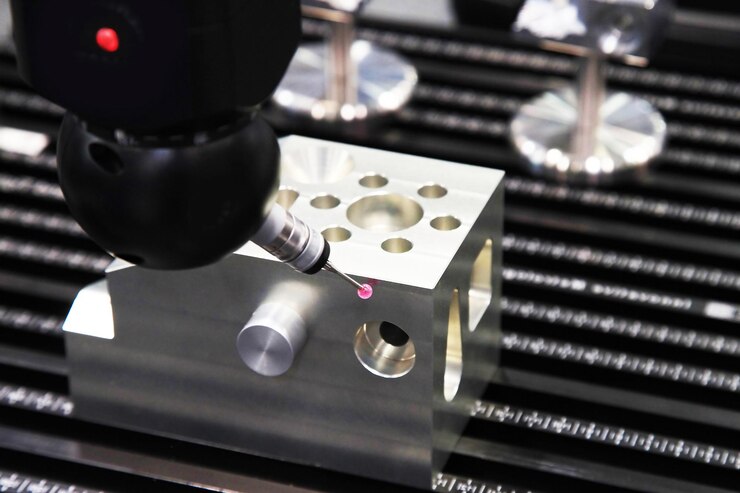

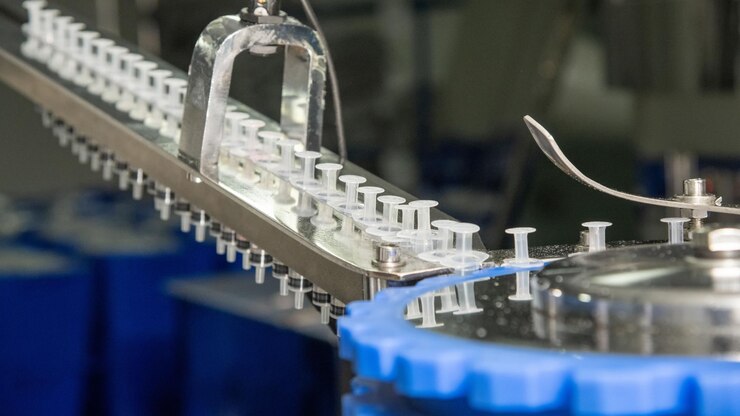

The Ultimate Guide to Custom Precision Injection Molds Custom precision injection molds are a decisive factor when it concerns the manufacturing of precise plastic parts with improved tolerance. These molds are used for all sorts of industries and needs such as automotive, medical and health, aerospace, electronics, etc. In this guide, we will be focusing

ACE Mold: One of the Leading Precision Mold Companies

Precision Mold Companies: Promoting Innovation in Industrial Processes In this article, we will discover what precision mold companies are why they are relevant, and their technologies. Also, we will focus on why it is crucial to choose the right precision mold manufacturer, and how your business can gain from custom molding. What are Precision Mold

Looking for Precision Injection Molders?

Precision Injection Molders: A Definitive Guide to High-Grade Injection Molding Services The world of manufacturing today requires the effective production of accurate and high-quality plastic components. Manufacturers from numerous industries require high-quality accurate and dependable precision injection molders for manufacturing complex and high-performance parts. In this article, you will be informed on the following aspects:

Top Trends in CNC Precision Mold Manufacturing for 2025

CNC Precision Mold Manufacturing: Global Trends for Innovating Modern Industries CNC precision manufacturing has come forward as one of the most critical manufacturing strategies today. When companies want to gain higher productivity, lower cost per product, and better quality products, then precision mold making is vital. Forming an essential part of medical devices, automobile manufacturing,