Guide To Design For Plastic Parts Molding In Injection Molding Injection-Molding

A Guide to Design for Plastic Parts Molding in Injection Molding Plastic parts molding is becoming the latest trend in plastic manufacturing companies. The injection molding technique for plastics is all the new rage. It is very important for a product to approve of client requirements. After all, customer satisfaction is of utmost priority. Another

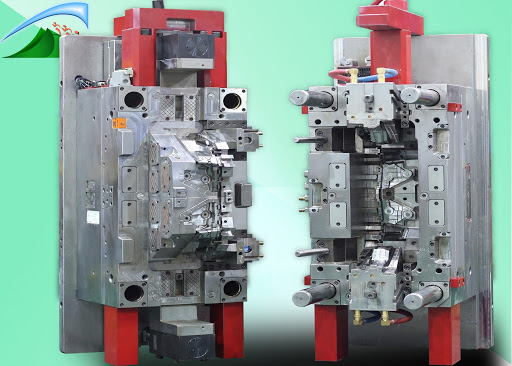

China Mold Maker: 5 Types of Plastic Injection Molds

In-Depth Review of China Mold Making China Mold maker is becoming one of the most renowned professionals of our times. The reason it is becoming popular is that it is a cheap technology that manufacturing industries utilize. And plastic molding with an injection technique goes hand in hand. The current demand for China Mold maker

Plastic Hardware Part Manufacture: 8 Factors in Plastic Part Design for Manufacturability

8 Factors that Influence DFM for Plastic Hardware Part Manufacture. Part design for manufacturability or DFM holds a vital position in the entire plastic hardware part manufacture process. Some reports suggest that molders may determine 70% of a product’s cost by the design decisions. These design decisions are taken during the DFM process. Part design

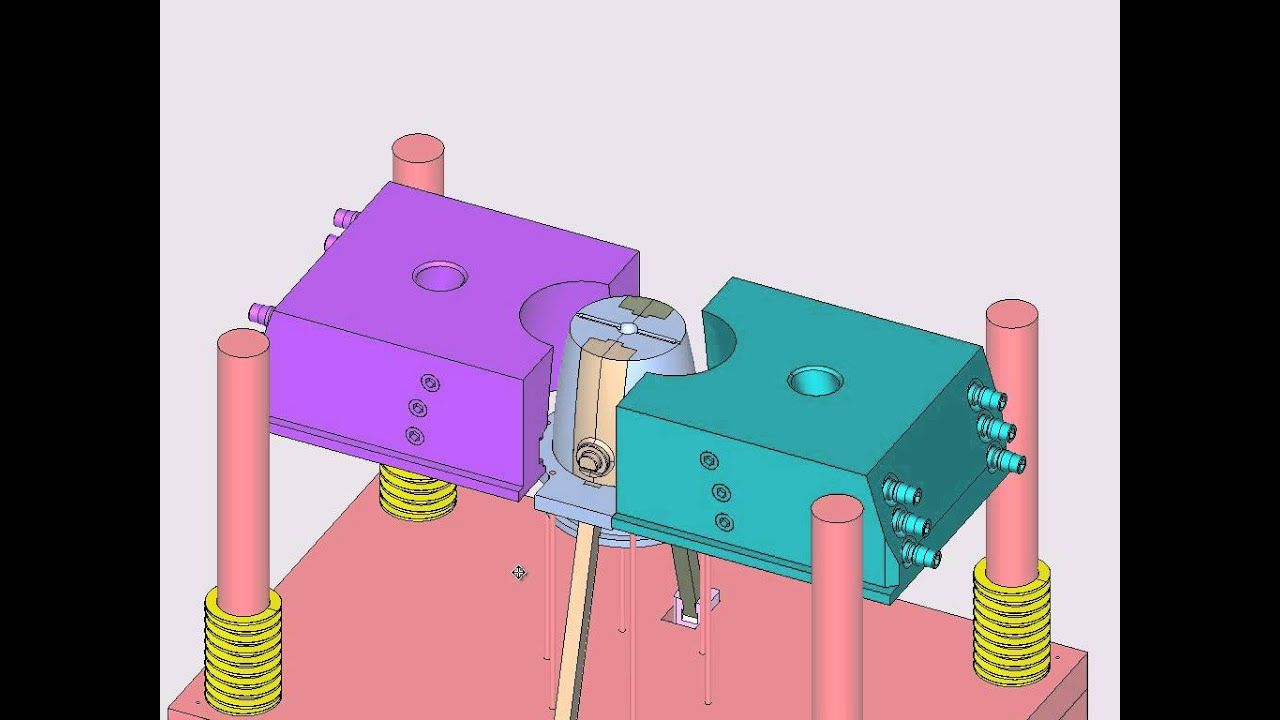

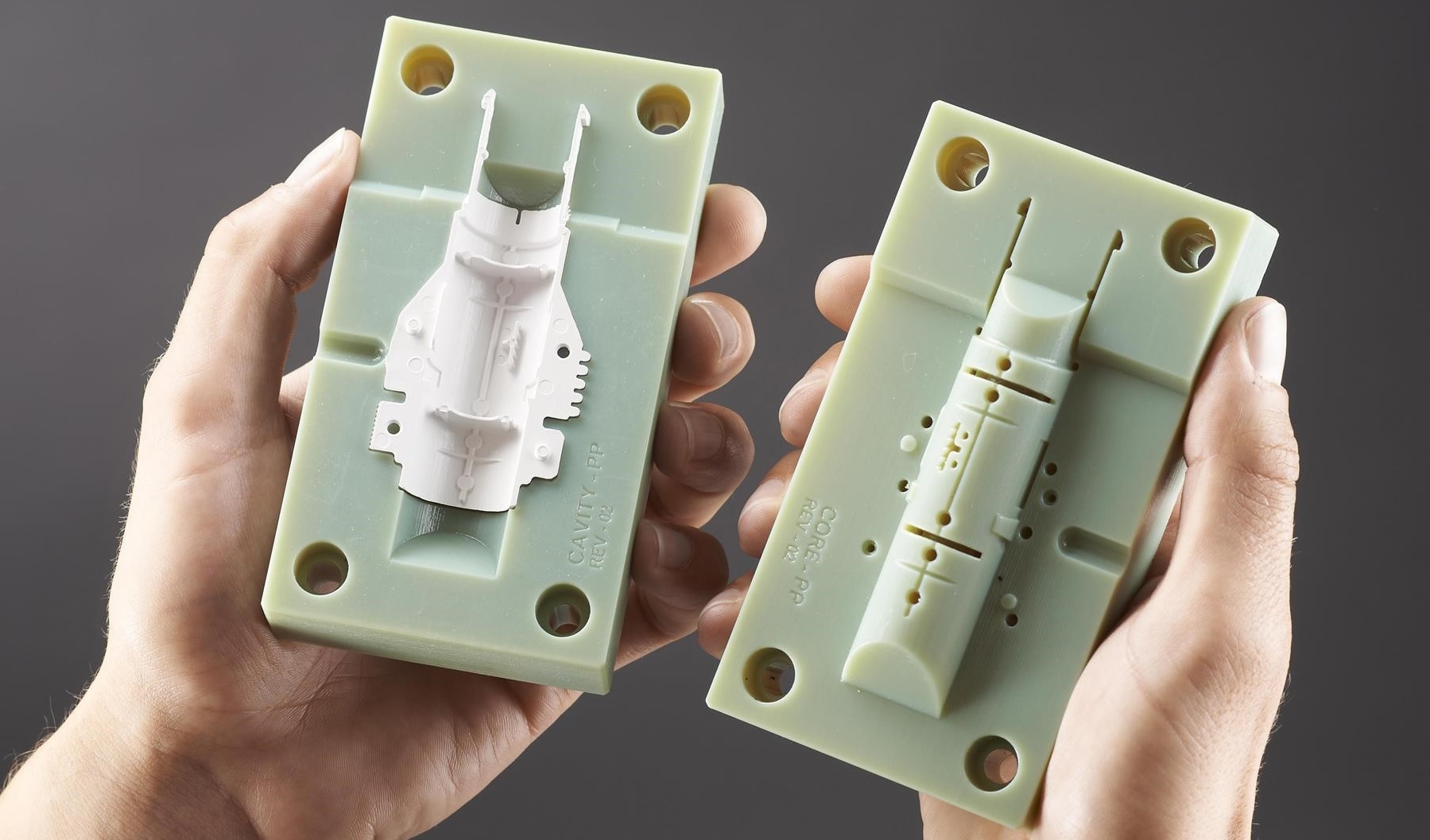

Importance of Prototype Tool in Injection Molding

What Makes A Prototype Tool Crucial for Injection Molding Process? A plastic molding prototype tool can define a production process’s success or failure before the process even begins. It does not predict but physically visualizes the end product specifications, geometric features, and performance characteristics. Therefore, it saves time, investment, and efforts. A plastic molding prototype