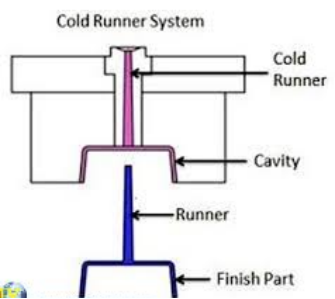

Why hot runner system is better than the cold runner system?

2 main categories of molds in injection molding Although plastic injection molding started its journey in the late 19th century, today the injection molding process has blossomed into one of the most versatile techniques. But molds still fall into two major categories such as hot runner and cold runner systems. Basically, both systems either they are

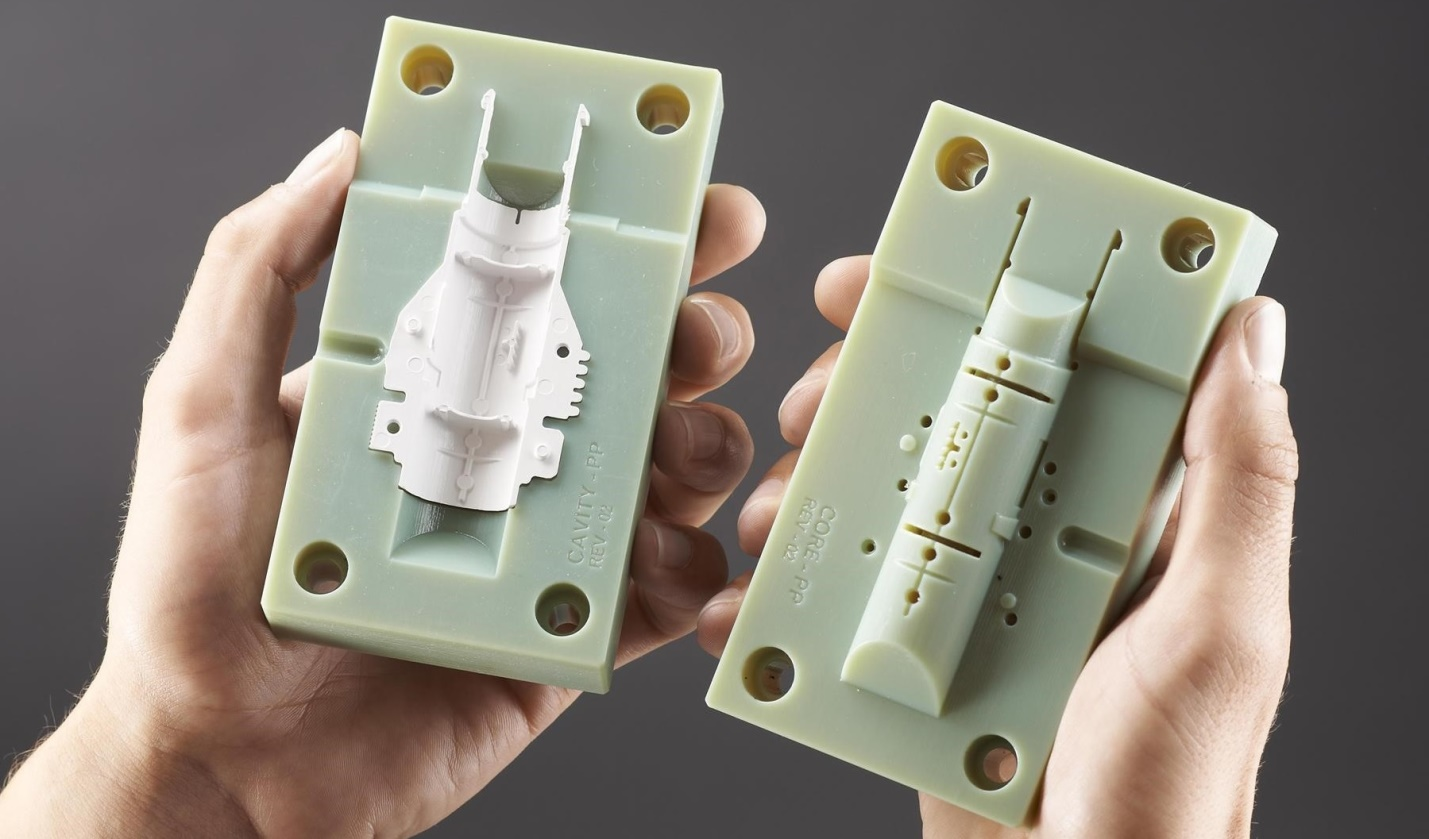

How to Choose OEM Tool Spare Parts Mold in 2023?

Tool spare parts molds are used to create molds for the production of spare parts for tools and machinery. These molds are typically made from high-quality materials such as steel or aluminum and are designed to be durable and long-lasting. The creation of tool spare parts molds requires careful planning and precision to ensure that

2 Best injection molding techniques for insert and over-mold

Insert and over-molding are two common techniques used in plastic injection molding. Insert molding involves placing metal or plastic components (inserts) into the mold before the injection process. The molten plastic is then injected around the insert, creating a strong bond between the two materials. Over-molding, on the other hand, involves molding one material over

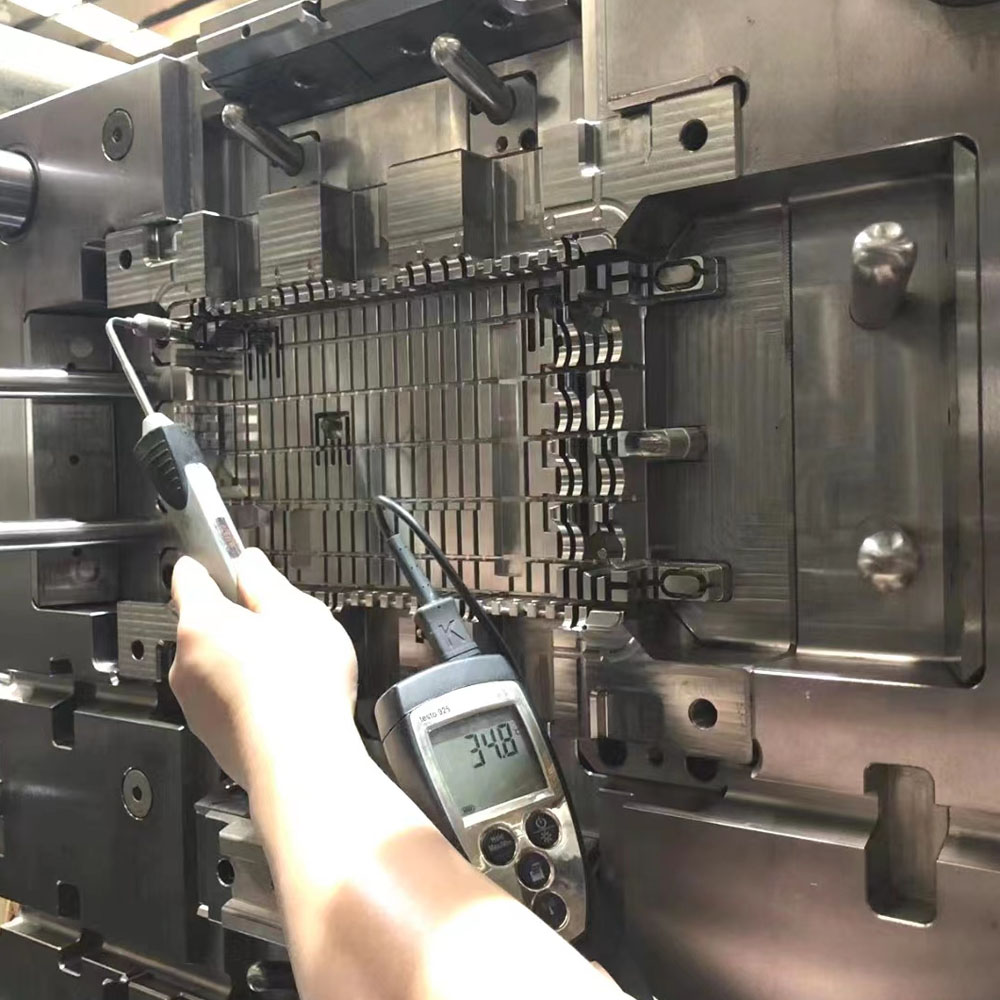

Critical factors to consider for designing ideal injection molding tool designs

Plastic injection molding is a highly preferred process for designing intricate shapes. Today injection molding has become one of the most preferred methods for creating identical plastic products in bulk. But it is extremely important to recognize the importance of injection molding tool designs for getting high-quality and cost-effective parts. In fact, tool designs are the