The cost of molding plastic products

You have a desire to produce plastic products, and industrial fan molds, and we have the opportunity to do it with high quality.

Let's start with the main thing.

What factors will determine the cost of plastic molding and industrial fan molds?

The number of items required. Generally, the production method comes by the circulation of the product. For example, plastic injection molding produces an expensive metal mold. This increase costs initially.

However, the more products produce with its help, the lower the cost of the product becomes.

Product material

For each project, thermoplastic resins come with optimal characteristics and an affordable price.

- Dimensions of the final product. The size of the product affects the consumption of material, as well as the cost of preparatory work.

- The complexity of the geometry of the product. The more complex the product design, the higher the cost of the work will be.

METHODS FOR THE MOLDING PLASTIC PRODUCTS

There are 3 ways of molding plastic products and industrial fan molds, depending on the circulation:

3D printing method. One of the most common methods of 3D printing - simulation by fusing layering on the printer FDM (Fused Deposition Modeling). FDM technology involves the production of three-dimensional objects using thermoplastic layering. Used for prototyping and small-batch production.

Other common 3D printing methods:

- Stereolithography (SLA-printing) - production of plastic products from liquid photopolymer resins. The resin hardens by irradiation with ultraviolet light. This method is more expensive than FDM printing, but 7 times more accurate.

- Selective laser sintering (SLS printing) is a method of sintering layers of powder material using high-power lasers.

How silicone mold helps you to get an exact copy?

Injection of plastic into a silicone mold involves molding parts in a vacuum and allows you to get an exact copy of the original object of your industrial fan molds. Furthermore, silicone molds are common in small batch production.

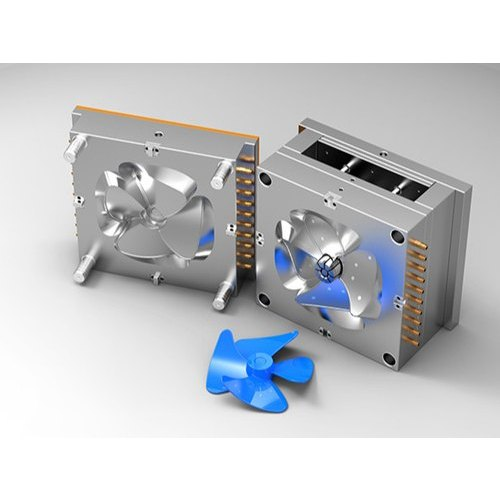

Injection molding of plastics takes place by injecting a molten polymer into a metal mold and then cooling it down. The casting method is common for large-scale production.

Let's compare the methods using the example of one product. Therefore, we have calculated the cost of production by different methods of a plastic case with dimensions of 165 mm ⅹ 95 mm 75 mm.

DIFFERENT STAGES OF PRODUCTION OF PLASTIC PRODUCTS

Injection of plastic into both silicone molds and molds begins with the design of a 3D model of the product in CAD programs (SolidWorks, AutoCAD, FreeCAD).

Next step after creating a 3D model

After creating a 3D model in digital form, we move on to making a prototype. Similarly, it will help you evaluate the functionality of the developed product. During the prototyping stages, design changes do not involve significant costs.

A prototype of a plastic product is made on a 3D printer. Similarly, a product made from a 3D printer has a layered surface.

If the requirements of producing your industrial fan molds are higher or it is necessary to obtain a larger volume of products at the output, we use the methods of casting plastics into molds.

Let's consider separately small-scale and large-scale production!

SMALL-SCALE PRODUCTION: INJECTION MOLDING OF PLASTICS INTO SILICONE

As a result, we get half of the silicone industrial fan mold for casting.

Then we repeat the process and get the other half of the mold. We connect the two form elements using a frame for rigidity. Similarly, fill the silicone mold with polyurethane and leave it in the chamber.

The setting time varies from 4 to 24 hours, depending on the type of plastic.

HIGH-VOLUME PRODUCTION: INJECTION MOLDING OF PLASTICS

In large-scale production, the most resource-intensive stage is the manufacture of a mold from metal. Molds are durable and make it possible to obtain products with high precision of detail.

First, the material hardens near the cold walls, then inside the casting body.

After cooling down, the mold opens, the product goes to the final processing stage and the mold to a new casting cycle. The cycle of producing industrial fan mold or other molded products completed by the final processing of the part: cutting off the sprue, milling, applying a soft-touch coating.

AN OVERVIEW OF MATERIALS FOR PLASTIC MOLDING

Generally, we consider the types of materials that are used for casting.

For 3D printing, as a rule, thermoplastics or composite materials based on them are good to use. Most popular types: polylactide, polyvinyl alcohol, nylon, metal imitators.

Can you imagine why? We tell you! Industrial fan molds maintenance is responsible for ensuring that everything works as smoothly as possible. In other words, it is a series of actions taken to maintain, sustain, repair or preserve something.

An industry can only reach its maximum productivity if the equipment works perfectly. For this, it is necessary to ensure that their maintenance is up to date!

Industrial fan molds Maintenance benefits

Maintenance not only keeps the production line running, it brings some other benefits that we have mentioned here. For example, the useful life of equipment.

The machines used in any factory are complex and costly. If something breaks and needs replacement, before the deadline, this will certainly bring great damage to the company.

With periodic maintenance, according to the needs of the equipment, it is possible to extend its useful life. As any anomalies will be quickly correct.

When an industrial fan molds business grows, its IT needs to expand with it. However, simply adding staff and adding new tools from scratch can cost more than expected and still take time to bring results. Therefore, choosing some form of IT outsourcing for your organization can make a difference.

How to outsource industrial fan molds projects?

Industrial fan molds outsourcing is a way to outsource industry services to external service providers. The idea is to use the skilled labor of a specialized company for part of the area's charges. So your industrial fan molds team can take on a more strategic role by focusing on what is needed for business growth.

To better understand how moulding outsourcing can be used within your company, it is first necessary to know the possible work modalities.