As one of the leading industrial hubs in the Midwest, Milwaukee has become a hotbed for plastic injection molding companies. From consumer products to automotive parts and medical devices, plastic injection molding is used to manufacture products of all shapes and sizes. But what is plastic injection molding and how is it revolutionizing manufacturing? In this blog post, we'll take a look at Milwaukee plastic injection molding companies and how they are transforming the manufacturing landscape.

Introduction to Milwaukee Plastic Injection Molding Companies

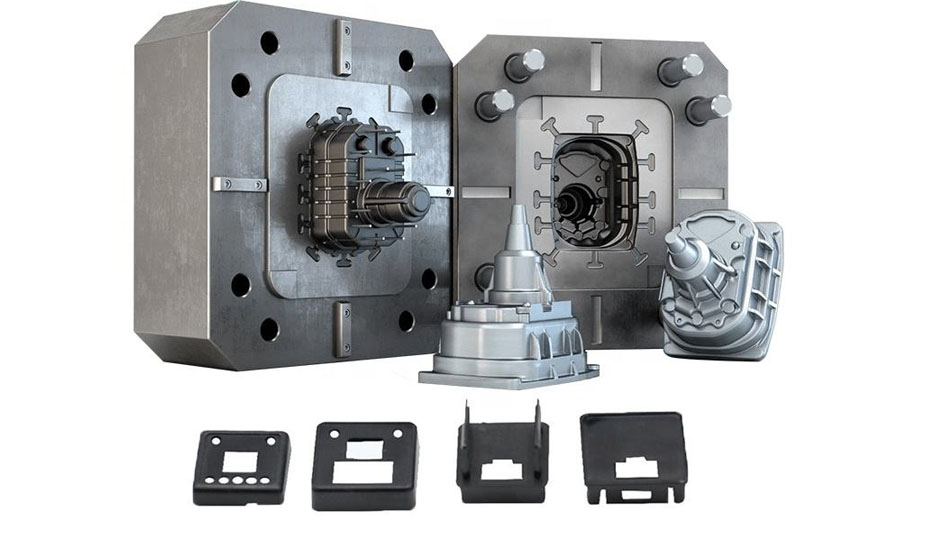

Plastic injection molding is a manufacturing process used to create a wide variety of plastic products. It involves injecting a heated plastic material into a mold, where it cools and hardens into the desired shape. Milwaukee is home to a number of highly successful plastic injection molding companies that specialize in creating custom products for a variety of industries.

The most notable Milwaukee plastic injection molding companies include Midwest Plastics, Lighthouse Plastics, and C&M Plastics. These companies have been in business for decades and are well-known for their high-quality products, quick turnaround times, and competitive prices. They are also leaders in the industry when it comes to new technologies and processes, making them ideal partners for businesses of all sizes.

Benefits of Milwaukee Plastic Injection Molding

Milwaukee plastic injection molding companies provide a wide range of benefits. Their experienced staff is highly skilled in the art of design and manufacturing, and they use the latest technologies to ensure precision and accuracy. This ensures that the products produced are of the highest quality and meet the customer’s specifications.

In addition, Milwaukee plastic injection molding companies are able to produce large volumes of products quickly and efficiently. This makes them ideal for businesses that require large quantities of products in a short period of time. Furthermore, the cost of plastic injection molding is typically lower than other manufacturing processes, making it an attractive option for businesses looking to reduce costs.

How Milwaukee Plastic Injection Molding Companies Are Revolutionizing Manufacturing

Milwaukee plastic injection molding companies are revolutionizing the manufacturing industry by developing new and innovative processes. By utilizing cutting-edge technologies, they are able to produce products with greater precision and accuracy than ever before. This has allowed them to create products that are more efficient and cost-effective, which has been a major boon for businesses in the Milwaukee area.

In addition, Milwaukee plastic injection molding companies are utilizing advanced materials and processes to produce products with unique properties. This has enabled them to create products that are stronger, lighter, and more durable than traditional products. These new materials and processes have allowed businesses to create products that are more efficient and cost-effective, while also providing them with a competitive edge.

Types of Plastic Injection Molding

Milwaukee plastic injection molding companies offer a wide range of services, including:

- Thermoplastic injection molding

- Thermoset injection molding

- Overmolding

- Insert molding

- Multi-component molding

Each type of plastic injection molding has its own set of benefits and applications. For example, thermoplastic injection molding is used to create products with complex shapes and intricate details, while thermoset injection molding is ideal for products that require high heat and pressure resistance.

The Design Process of Plastic Injection Molding

In order for a product to be successfully produced through plastic injection molding, there are a few key steps that must be taken. The first step is to design a mold that is capable of producing the desired product. This involves using 3D CAD software to create a detailed digital model of the product. Once the model is complete, it is then sent to a CNC machine that is used to create a physical mold.

The next step is to create a prototype of the product. This is done by using a 3D printer to create a prototype of the product using the digital model. The prototype is then tested to ensure that it meets the customer’s specifications. Once the prototype is approved, the production process can begin.

Advantages of Plastic Injection Molding

Plastic injection molding offers a number of advantages over other manufacturing processes. It is a fast, cost-effective way to produce large volumes of products with precision and accuracy. It also allows for the creation of products with unique properties, such as strength, lightness, and durability.

Additionally, plastic injection molding is a versatile process that can be used to create a wide variety of products. From consumer products to medical devices, plastic injection molding is used to manufacture products of all shapes and sizes. This makes it an ideal choice for businesses looking to create custom products.

Challenges Faced by Milwaukee Plastic Injection Molding Companies

Despite its many benefits, plastic injection molding is not without its challenges. One of the biggest challenges faced by Milwaukee plastic injection molding companies is keeping up with the latest technologies. New technologies and processes are constantly being developed, and plastic injection molding companies must stay up-to-date in order to remain competitive.

Additionally, Milwaukee plastic injection molding companies must also stay abreast of market trends. By understanding what customers are looking for, these companies can ensure that their products meet the customer’s needs and remain competitive in the market.

How Milwaukee Plastic Injection Molding Companies Are Keeping Up With Market Trends

Milwaukee plastic injection molding companies are keeping up with market trends by utilizing the latest technologies and processes. They are also taking advantage of new materials and processes to create products with unique properties. Additionally, they are staying up-to-date on customer needs and preferences in order to create products that are more efficient and cost-effective.

Tips for Hiring Top Plastic Injection Molding Companies in Milwaukee

When looking for a plastic injection molding company in Milwaukee, it is important to do your research. Make sure to ask questions about the company’s experience, capabilities, and technologies. You should also ask for references and case studies to get a better understanding of the company’s capabilities.

It is also important to make sure that the company you are considering is up-to-date on market trends. This will ensure that the products they create are in line with customer needs and preferences. Furthermore, you should make sure that the company is willing to work with you to create a product that meets your specifications.

Conclusion

Milwaukee plastic injection molding companies are revolutionizing the manufacturing industry with their cutting-edge technologies and processes. From consumer products to medical devices, they are able to create products with unique properties that are more efficient and cost-effective. By understanding market trends and utilizing the latest technologies, these companies are able to remain competitive and create products that meet customer needs.

If you are looking for a top-notch plastic injection molding company in Milwaukee, make sure to do your research and ask the right questions. By doing so, you will be able to find a reliable partner that can help you create the product of your dreams.