Injection molding is a manufacturing process in which a material, such as plastic, is heated and then injected into a mold. The mold is a hollowed-out form in the shape of the desired product. The material then cools and solidifies, taking on the shape of the mold. Injection molding is used to create a wide variety of products, including automotive parts, medical devices, household items, and toys. It is a highly efficient and cost-effective way to produce large quantities of identical products.

Injection moulding products are everywhere. From the parts of your car to the plastic parts of the toys your children play with, injection moulding has revolutionized manufacturing and product design. But what are the benefits of injection moulding? How does injection moulding work and what types of products can be made with it? In this blog post, we'll explore the benefits of creating custom injection moulding products and what to consider when making your own.

Introduction to Injection Moulding Products

Injection moulding is a process used to create intricate plastic parts and components. It involves melting a plastic material, such as polypropylene or polyethylene, and then injecting it into a mold. The mold is a hollow cavity that has been designed to create a particular shape or design. The molten plastic cools and solidifies within the mold, creating a precise product that can be used in a variety of applications.

Injection moulding is a highly efficient process that can quickly create products with intricate details and high levels of precision. The process is also highly cost-effective and can be used to create products in a wide range of shapes, sizes, and materials. Injection moulding is used in a variety of industries, including automotive, medical, and consumer products.

What Are the Benefits of Injection Moulding?

Injection moulding offers many advantages over other manufacturing processes. It is a fast and cost-effective way to produce parts and components with intricate details and high levels of accuracy. It also offers greater flexibility in design than other processes, as it can be used to create products in a wide range of shapes, sizes, and materials. Additionally, injection moulding is a highly efficient process, as it can produce high volumes of parts in a short amount of time.

Injection moulding also offers a number of environmental benefits. The process requires minimal waste, as any excess material can be recycled and reused. Additionally, injection moulding requires less energy than other processes, as it does not require a large amount of energy to heat and cool the materials.

How Does Injection Moulding Work?

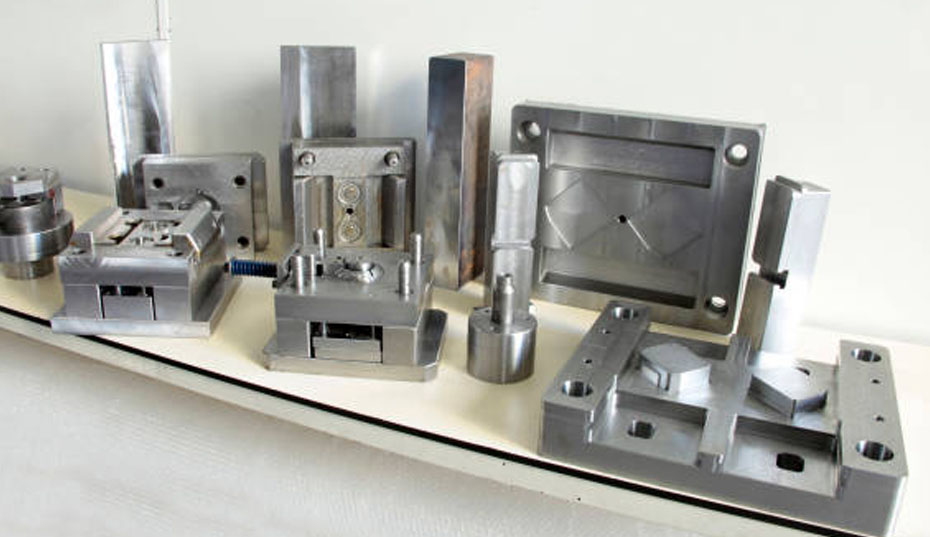

The injection moulding process begins with the design of a mold, which is a hollow cavity that is designed to create a particular shape or design. The mold is then filled with molten plastic, which is injected into the mold under pressure. The molten plastic is then cooled and solidified, creating a precise product that has been designed to exact specifications.

Injection moulding machines can be used to produce a wide range of products, from small plastic parts to complex components. The machines can be programmed to produce products with intricate details and high levels of accuracy. Additionally, the machines can be used to create products in a wide range of shapes, sizes, and materials.

What Types of Products Can Be Made With Injection Moulding?

Injection moulding is used to create a wide range of products, from small plastic parts to complex components. The process can be used to create products in a wide range of shapes, sizes, and materials.

Injection moulding is commonly used to create parts for the automotive, medical, and consumer products industries. The process can be used to create components for cars, medical devices, toys, and a variety of other products. Additionally, injection moulding can be used to create products for the aerospace, electronics, and packaging industries.

Injection moulding is also used to create custom products. Companies can use the process to create products with intricate details and high levels of accuracy. The process can also be used to create products in a wide range of shapes, sizes, and materials.

What Are the Benefits of Creating Custom Injection Moulding Products?

Creating custom injection moulding products offers a number of advantages. It allows companies to create products with precise details and high levels of accuracy. Additionally, custom injection moulding products can be made in a wide range of shapes, sizes, and materials.

Custom injection moulding products can also be created quickly and cost-effectively. The process is highly efficient and can be used to create high volumes of parts in a short amount of time. Additionally, the process requires minimal waste, as any excess material can be recycled and reused.

Creating custom injection moulding products also allows companies to create products that are unique and tailored to their specific needs. Companies can create products that are designed to meet their exact specifications and requirements.

What Materials Can Be Used in Injection Moulding?

Injection moulding can be used to create products in a wide range of materials. Common materials used in injection moulding include polypropylene, polyethylene, ABS, and nylon. Each material has its own unique properties, which make it suitable for certain applications.

When selecting a material for injection moulding, it is important to consider the properties of the material and how it will be used. Factors such as strength, flexibility, and durability should be taken into account. Additionally, the cost of the material should be considered, as some materials may be more expensive than others.

How to Design a Custom Injection Moulding Product

Designing a custom injection moulding product is a complex process that requires careful consideration. The design of the product should include factors such as the size, shape, and material of the product, as well as the desired level of precision. Additionally, the design should take into account the type of injection moulding machine that will be used.

It is important to work with an experienced injection moulding partner when designing a custom product. An experienced partner can help to ensure that the product is designed to exact specifications and is suitable for the intended application. Additionally, an experienced partner can provide advice on the best materials to use and the most cost-effective production methods.

What to Consider When Selecting an Injection Moulding Partner

When selecting an injection moulding partner, it is important to consider a number of factors. The partner should have experience in the injection moulding process and be able to provide advice on the best materials and production methods. Additionally, the partner should be able to provide a high level of customer service and be able to deliver the product on time and on budget.

The partner should also have an established track record of producing high-quality products. It is important to check references and customer reviews to ensure that the partner is reliable and trustworthy. Additionally, the partner should be able to provide a guarantee of quality and be willing to stand behind their products.

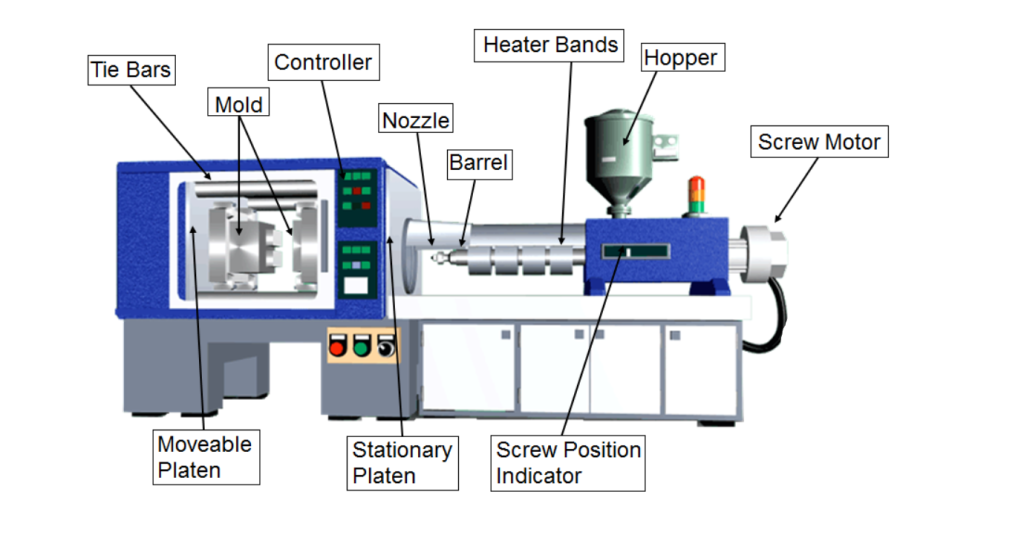

What to Look for in an Injection Moulding Machine

When selecting an injection moulding machine, it is important to consider a number of factors. The machine should be able to handle the materials and the type of product being produced. Additionally, the machine should be able to produce the desired level of accuracy and have a high level of efficiency.

The machine should also be durable and reliable, as it will be used to produce high volumes of parts. Additionally, the machine should be easy to use and maintain and have a low cost of ownership. It is also important to consider the cost of the machine, as some machines may be more expensive than others.

Conclusion

Injection moulding is a highly efficient process that can quickly create products with intricate details and high levels of precision. The process offers a number of advantages, including cost-effectiveness, flexibility in design, and environmental benefits. Additionally, injection moulding can be used to create custom products that are designed to meet exact specifications and requirements.

When creating custom injection moulding products, it is important to consider a number of factors. The design of the product should include factors such as the size, shape, and material of the product, as well as the desired level of precision. Additionally, it is important to select an experienced injection moulding partner and a reliable injection moulding machine.

Injection moulding is a highly efficient and cost-effective process that can be used to create a wide range of products. The process offers a number of benefits, including flexibility in design, environmental benefits, and the ability to create custom products. By understanding the process and the benefits it offers, companies can use injection moulding to create products that are tailored to their exact specifications and requirements.