Are you looking for injection moulding near you? If so, you're in luck! Injection moulding is a popular manufacturing process used to produce plastic parts and components. In this article, we'll go over what injection moulding is, its benefits, how to find injection moulding near you, and more. So, let's get started!

What is injection moulding?

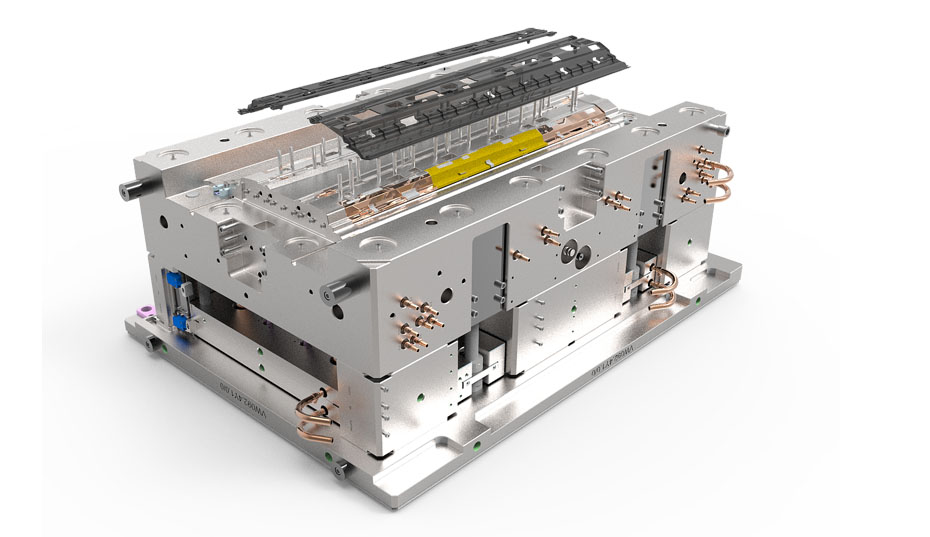

Injection moulding is a manufacturing process used to produce parts and components from plastic and other materials. In this process, molten material is injected into a mould cavity, where it is cooled and solidified. The finished product is then released from the mould. Injection moulding is used to make a wide range of products, from medical devices to automotive parts.

The injection moulding process begins with the preparation of the mould. This includes designing and building the mould according to the customer's specifications. Once the mould is ready, the molten material is injected into the mould cavity. Depending on the material used, it can take anywhere from a few seconds to several minutes for the material to cool and solidify. After it has cooled, the finished product is released from the mould.

Injection moulding is a fast and efficient way to produce large quantities of parts and components. It is also cost-effective, as the cost of producing each part is relatively low. Additionally, the injection moulding process allows for precise control over the shape and size of the parts produced.

Benefits of injection moulding

Injection moulding offers several benefits to manufacturers. Here are some of the main benefits of injection moulding:

- Cost-effective production: Injection moulding is a cost-effective way to produce large quantities of parts and components.

- Precision: The injection moulding process allows for precise control over the shape and size of the parts produced.

- Versatility: Injection moulding can be used to produce a wide range of products from medical devices to automotive parts.

- Durability: The parts produced through injection moulding are highly durable, as they are made from strong, durable materials.

- Efficiency: The injection moulding process is fast and efficient, allowing manufacturers to quickly produce large quantities of parts.

Injection moulding statistics

Injection moulding is one of the most popular manufacturing processes used today. According to a 2017 study, injection moulding accounted for 28% of all plastic parts produced. Additionally, the study found that injection moulding is used to produce parts for a wide range of industries, including automotive, medical, and consumer electronics.

Injection moulding is also one of the most cost-effective manufacturing processes. According to a 2016 study, injection moulding is the most cost-effective manufacturing process for producing small and medium-sized parts. Additionally, the study found that injection moulding is often more cost-effective than other manufacturing processes, such as machining, for producing large parts.

How to find injection moulding near me

Now that you know what injection moulding is and its benefits, you may be wondering where to find injection moulding near you. Fortunately, there are several ways to find injection moulding services near you. Here are some tips for finding the best injection moulding companies near you:

- Check online directories: One of the easiest ways to find injection moulding near you is to check online directories, such as Google Maps or Yelp. These directories will list local injection moulding services, as well as customer reviews and ratings.

- Ask for referrals: Another way to find injection moulding near you is to ask for referrals from friends, family, or colleagues who have used injection moulding services in the past. This is a great way to get a firsthand recommendation of a reliable injection moulding company.

- Read online reviews: Reading online reviews can also help you find a reliable injection moulding company near you. Look for reviews from customers who have used the company's services in the past. This can help you get an idea of the quality of the company's services.

Different types of injection moulding

Injection moulding is a versatile manufacturing process that can be used to produce a wide range of parts and components. Here are some of the different types of injection moulding:

- Plastic injection moulding: This is the most common type of injection moulding. It is used to produce parts and components from plastic materials, such as polypropylene, polyethylene, and ABS.

- Metal injection moulding: This type of injection moulding is used to produce parts and components from metal materials, such as stainless steel, aluminum, and bronze.

- Rubber injection moulding: This type of injection moulding is used to produce parts and components from rubber materials, such as silicone, neoprene, and nitrile.

- Ceramic injection moulding: This type of injection moulding is used to produce parts and components from ceramic materials, such as porcelain and clay.

Tips for finding the best injection moulding company

Once you have found some injection moulding companies near you, it is important to find the best one for your needs. Here are some tips for finding the best injection moulding company:

- Experience: Look for a company that has a lot of experience in injection moulding. This will ensure that they have the expertise to produce high-quality parts and components.

- Quality: Make sure to check the quality of the company's work. Ask for samples of their work, or look for customer reviews and ratings.

- Cost: Make sure to compare the cost of different injection moulding companies. This will help you find the most cost-effective option for your needs.

- Service: Look for a company that offers excellent customer service. This will ensure that you get the help and advice you need to get the most out of your injection moulding services.

Injection moulding services

In addition to injection moulding, many companies offer additional services related to the injection moulding process. Here are some of the most common injection moulding services:

- Design: Many companies offer design services to help you create the perfect mould for your project.

- Finishing: Companies can provide finishing services to help you create a smooth and polished finish for your parts and components.

- Testing: Companies can provide testing services to ensure that your parts and components meet the necessary standards for quality and safety.

- Engineering: Companies can provide engineering services to help you make sure that your parts and components are designed to last.

Injection moulding courses

If you are interested in learning more about injection moulding, there are several courses available. These courses will teach you the basics of injection moulding, such as injection mould design and troubleshooting. Additionally, many courses will also provide hands-on experience with injection moulding machines.

Injection moulding materials

Injection moulding can be used to produce parts and components from a wide range of materials, including plastic, metal, rubber, and ceramic. Here are some of the most common materials used in injection moulding:

- Plastic: Plastic is the most common material used in injection moulding. It is strong, durable, and cost-effective.

- Metal: Metal is a popular choice for injection moulding, as it can produce parts and components with a high degree of accuracy and precision.

- Rubber: Rubber is a great choice for injection moulding, as it can produce parts and components with excellent durability and flexibility.

- Ceramic: Ceramic is a popular choice for injection moulding, as it can produce parts and components with a high degree of accuracy and precision.

Conclusion

In conclusion, injection moulding is a popular manufacturing process used to produce parts and components from plastic and other materials. It offers several benefits, including cost-effectiveness, precision, and durability. Additionally, injection moulding can be used to produce a wide range of products from medical devices to automotive parts. If you're looking for injection moulding near you, there are several ways to find the best injection moulding companies. From checking online directories to asking for referrals, you can find the perfect injection moulding company for your needs. Finally, if you're interested in learning more about injection moulding, there are several courses available that can teach you the basics of the process.