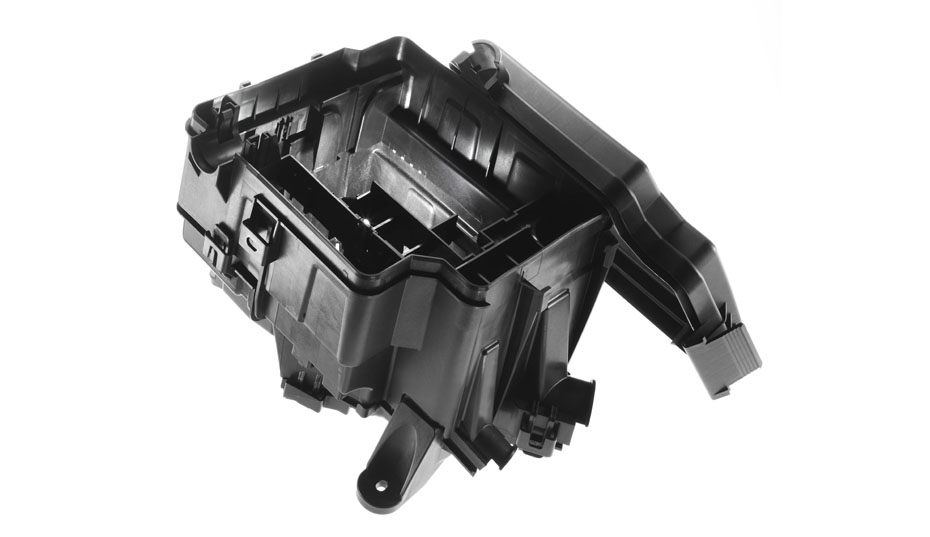

Injection molded plastic packaging is a manufacturing process used to produce plastic parts for packaging applications, such as bottles, jars, caps, closures, and containers. The process involves melting plastic pellets or granules and injecting them into a mold cavity under high pressure, where they solidify and take on the shape of the mold.

The advantages of injection molding for packaging applications include:

- High production rates: Injection molding allows for high volume production of plastic parts at a low cost per unit.

- Design flexibility: Injection molding allows for the production of complex shapes and designs, including intricate features such as threads, ribs, and other details.

- Material versatility: Injection molding can process a wide range of thermoplastics, including polyethylene, polypropylene, PET, PVC, and many others.

- Consistency: Injection molding provides consistent and repeatable part quality, making it ideal for large-scale manufacturing.

Injection molded plastic packaging is used in a wide range of industries, including food and beverage, pharmaceutical, personal care, and household products. The process can produce a variety of packaging types, such as rigid containers, flexible pouches, and closures.

Injection molded plastic packaging is a versatile and efficient form of packaging for a variety of products. It provides protection, durability, and convenience for customers, and has become a popular choice for many businesses. In this article, we will discuss the benefits of injection molded plastic packaging, the types of injection molded plastic packaging, design considerations, and the injection molding process.

What is Injection Molded Plastic Packaging?

Injection molded plastic packaging is a form of packaging made from plastic material. This packaging is created by injecting molten plastic into a mold, which is then cooled and formed into the desired shape. This method of packaging is cost-effective and produces high-quality results with a consistent finish. Injection molded plastic packaging is a popular choice for many businesses because it is durable, lightweight, and provides excellent protection for the product.

Benefits of Injection Molded Plastic Packaging

Injection molded plastic packaging offers many benefits for businesses and customers alike. It is a cost-effective form of packaging that is lightweight and provides excellent product protection. Additionally, injection molded plastic packaging is durable and can withstand a variety of environmental conditions. This makes it an ideal option for storing and shipping products.

Injection molded plastic packaging also offers design flexibility. Complex shapes and structures can be created with injection molded plastic packaging, allowing for unique and eye-catching designs. This can be beneficial for businesses that want to stand out from the competition.

In addition to these benefits, injection molded plastic packaging is also recyclable and environmentally friendly. This makes it an ideal choice for businesses that want to reduce their carbon footprint and promote sustainable packaging solutions.

Types of Injection Molded Plastic Packaging

Injection molded plastic packaging comes in a variety of shapes and sizes. Common types of injection molded plastic packaging include bottles, jars, boxes, trays, and blister packs. Each type of injection molded plastic packaging has its own unique benefits and drawbacks, so it’s important to choose the right type for your product.

Bottles are a popular choice for packaging liquids and other products that require a secure seal. Bottles come in a variety of shapes and sizes, allowing for a great deal of design flexibility. Jars are a great option for packaging dry goods, such as snacks and spices.

Boxes are a great choice for packaging items that need extra protection. They can be printed with custom designs to add a unique touch to your product. Trays are often used to package and display products in stores, while blister packs are a great option for packaging small products that need to be locked in place.

Structural and Design Considerations for Injection Molded Plastic Packaging

When designing injection molded plastic packaging, it’s important to consider the structural and design needs of the product. The type of plastic material used for the packaging should be chosen based on the needs of the product. For example, if the product needs to be waterproof or heat-resistant, a different type of plastic material should be used. Additionally, the shape and design of the packaging should be chosen based on the product’s needs. For example, if the product needs to be securely sealed, a bottle or jar should be used.

When designing the packaging, it’s also important to consider the aesthetics of the product. Color, texture, and other design elements should be chosen to create an eye-catching design that resonates with customers.

Injection Molding Process

The injection molding process is the process used to create injection molded plastic packaging. This process involves injecting molten plastic into a mold, which is then cooled and formed into the desired shape. Injection molding is a cost-effective and efficient way to produce high-quality packaging quickly. Additionally, injection molding is a scalable process, meaning it can be used to produce large or small quantities of packaging.

Advantages of Injection Molded Plastic Packaging

Injection molded plastic packaging offers many advantages for businesses and customers alike. It is a cost-effective form of packaging that is lightweight and provides excellent product protection. Additionally, injection molded plastic packaging is durable and can withstand a variety of environmental conditions. This makes it an ideal option for storing and shipping products.

Injection molded plastic packaging also offers design flexibility. Complex shapes and structures can be created with injection molded plastic packaging, allowing for unique and eye-catching designs. This can be beneficial for businesses that want to stand out from the competition.

In addition to these advantages, injection molded plastic packaging is also recyclable and environmentally friendly. This makes it an ideal choice for businesses that want to reduce their carbon footprint and promote sustainable packaging solutions.

Disadvantages of Injection Molded Plastic Packaging

Injection molded plastic packaging does have some drawbacks. The process can be expensive, as the molds used to create the packaging must be purchased and maintained. Additionally, the process can be time-consuming, as the molds must be cooled and cleaned between batches.

Injection molded plastic packaging also has limited design flexibility. Complex designs may require the use of multiple molds, which can add to the cost and time of production. Additionally, some plastic materials are not suitable for food products, which can limit the use of injection molded plastic packaging for certain products.

Applications of Injection Molded Plastic Packaging

Injection molded plastic packaging is used for a variety of products, including food and beverage, pharmaceuticals, cosmetics, electronics, and more. It is a versatile form of packaging that can be used for a variety of products.

Food and beverage products are often packaged in injection molded plastic packaging, as it provides excellent product protection and is easy to clean. Pharmaceuticals and cosmetics are also commonly packaged in injection molded plastic packaging, as the packaging is durable and tamper-proof. Electronics are often packaged in injection molded plastic packaging, as it provides a lightweight and secure solution for shipping and storing these products.

Best Practices for Injection Molded Plastic Packaging

When considering injection molded plastic packaging for your product, it’s important to consider the best practices for this type of packaging. The type of plastic material should be chosen based on the needs of the product, and design elements should be chosen to create an eye-catching design that resonates with customers. Additionally, the injection molding process should be considered, as it is an efficient and cost-effective way to produce high-quality packaging quickly.

Conclusion

Injection molded plastic packaging is an efficient and cost-effective form of packaging that is well-suited for a variety of products. It provides protection, durability, and convenience for customers, and is a popular choice for many businesses. In this article, we have discussed the benefits of injection molded plastic packaging, the types of injection molded plastic packaging, design considerations, and the injection molding process. We hope this article has been helpful in understanding the benefits of injection molded plastic packaging and best practices for using this type of packaging.