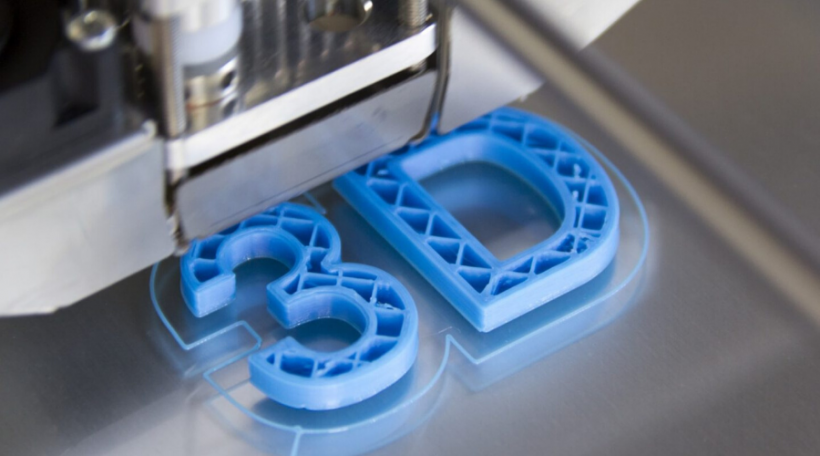

In the world of 3D printing, creating objects that are not only aesthetically pleasing but also strong and durable is a common goal for many enthusiasts and professionals. Whether you're creating functional prototypes or artistic pieces, having strong 3D prints can make a significant difference in their performance and longevity. In this comprehensive guide, we will explore various techniques and strategies to help you achieve stronger 3D prints.

Understanding the Challenges of Weak 3D Prints

Weakness in 3D prints can arise from various factors, including moisture absorption in the filament, inadequate infill density, insufficient wall thickness, and poor layer adhesion. To address these challenges and ensure stronger prints, we will delve into specific solutions for each issue.

Drying Filament to Prevent Moisture Absorption

Moisture accumulation in 3D printing filament can lead to weak and brittle prints. When filament absorbs moisture from the air, it can result in bubbles and popping during the printing process, compromising the structural integrity of the object. To combat this, it is crucial to dry the filament effectively.

Drying filament can be achieved through different methods. One popular approach is to place the filament spool in an oven at low heat. However, it's important to calibrate the oven temperature with a thermometer, as oven temperatures can be inaccurate, especially at lower settings.

Alternatively, you can invest in a specialized filament dryer like the SUNLU Filament Dryer. This device has received positive feedback from users, particularly those working with moisture-absorbent materials like Nylon. By using a filament dryer, you can effectively remove moisture from the filament, resulting in cleaner and stronger prints.

"I have been using the SUNLU Filament Dryer for my Nylon prints, and the difference is remarkable. My prints now come out clean and beautiful." - Happy user (source)

It is recommended to use additional insulation, such as a large plastic bag or a cardboard box, to retain heat and improve the drying process.

Choosing Stronger Materials

The choice of filament material plays a vital role in determining the strength of your 3D prints. While some materials may be inherently weak, others offer superior strength and durability. Opting for stronger materials can significantly enhance the overall performance of your prints.

One such material gaining traction in the 3D printing community is Polycarbonate with Carbon Fiber Reinforcement. This filament, available on platforms like Amazon, provides excellent strength in 3D prints and has garnered positive reviews from users. Its ease of printing, compared to other strong materials like ABS, makes it a popular choice among enthusiasts.

Another widely used filament known for its strength is OVERTURE PETG 1.75mm Filament. This filament offers improved strength over PLA and is relatively easy to print with. It is an excellent option for creating functional 3D prints that require higher strength.

"I have been using OVERTURE PETG filament for my projects, and it has proven to be stronger than PLA. The prints come out great, and it's easy to work with." - Satisfied user (source)

When choosing filament materials, consider the specific requirements of your project and select a material that aligns with your desired strength and durability.

Strengthening Techniques for 3D Prints

Now that we have addressed the challenges of weak 3D prints and explored options for using stronger materials, let's delve into specific techniques to strengthen your prints. These techniques range from adjusting print settings to utilizing post-processing methods.

1. Adjusting Print Settings for Strength

Fine-tuning your print settings is crucial for achieving stronger 3D prints. There are several key settings that can be adjusted to improve strength, including infill percentage, surface thickness, layer height, and extrusion width.

Increasing the infill percentage can enhance the strength of your prints. A higher infill percentage means more material inside the object, resulting in improved structural integrity. However, it's important to find the right balance, as excessively high infill percentages can lead to longer print times and increased material consumption.

Another often overlooked setting is the infill overlap, which affects the bond between perimeters and infill. Increasing the infill overlap slightly can improve the adhesion between these layers and contribute to stronger prints.

Additionally, adjusting the extrusion width can have a significant impact on print strength. Increasing the extrusion width up to 150% - 200% of the nozzle diameter allows for more material to be deposited per pass, resulting in stronger layer bonding and improved overall strength.

2. Optimizing Infill Patterns and Number of Perimeters

The choice of infill pattern and the number of perimeters can greatly influence the strength of your 3D prints. While the honeycomb pattern is generally stronger for prints with less than 50% infill, the rectilinear pattern surpasses it in strength for denser prints with over 50% infill. Rectilinear patterns also offer the advantage of faster print times compared to honeycomb patterns.

In terms of the number of perimeters, increasing the number has a greater impact on print strength than increasing infill density. Thicker walls provide more strength to withstand external forces, making them more useful than higher internal density. However, it's essential to strike a balance between wall thickness and infill density to ensure optimal strength-to-weight ratio.

"Increasing the number of perimeters has a greater impact on strength than increasing infill density. Thicker walls provide more strength to withstand external forces, making them more useful than higher internal density." - CNC Kitchen

3. Choosing the Right Layer Height

Layer height plays a crucial role in the strength of your 3D prints. Thinner layers generally result in better layer adhesion and denser parts. A layer height of 0.1mm (100 microns) is recommended for maximizing strength, as it promotes better bonding between layers. However, the strength drop-off associated with going to 0.2mm (200 microns) is minimal, making it a worthwhile trade-off to reduce print time by 25%.

It's important to note that adjusting layer height requires considering other print settings, such as print temperature and extrusion multiplier, to accommodate the thicker stream of plastic being deposited. Failure to make these adjustments can result in under-extrusion and weaker prints.

4. Controlling Cooling for Improved Layer Adhesion

While cooling is beneficial for achieving better surface quality and handling overhangs, it can negatively impact layer adhesion and, consequently, print strength. Cooling causes each layer to solidify quickly, reducing the time for proper bonding between layers. Depending on the material being printed, it may be necessary to reduce or disable cooling to ensure optimal layer adhesion and overall strength.

PLA, for example, benefits from cooling to improve surface quality. However, it is essential to strike a balance between cooling and print strength by setting the cooling fan to the lowest power that still achieves the desired surface quality.

5. Post-Processing Techniques for Strengthening

In addition to optimizing print settings, post-processing techniques can further enhance the strength of your 3D prints. Here are a few methods worth considering:

Annealing 3D Prints

Annealing is a heat treatment process that involves subjecting 3D printed objects to increased temperatures to strengthen their integrity. This process can significantly improve the strength of prints, with some tests showing an increase of up to 40%. The specific temperature and duration of the annealing process depend on the material used. Josef Prusa's video on annealing provides valuable insights and demonstrates the effects of annealing on various materials like PLA, ABS, PETG, and ASA.

Electroplating 3D Prints

Electroplating is a post-processing technique that can enhance the strength of 3D prints while also providing a durable and long-lasting finish. This process involves immersing the printed part in a water and metal salt solution and passing an electric current through it. The current causes metal cations to deposit and form a thin coating around the part, resulting in increased strength. Zinc, chrome, and nickel are commonly used plating materials that offer industrial-grade strength.

Epoxy Coating

Applying an epoxy coating to finished 3D prints can significantly strengthen the objects. Epoxy, a polyepoxide compound, acts as a functional hardener that reinforces the structure of the print. By applying a thin and even layer of epoxy using a brush, you can enhance the strength and durability of the print. The XTC-3D High Performance Print Coating is a popular epoxy coating used by many 3D printing enthusiasts. It is compatible with various materials like PLA, ABS, SLA prints, wood, and paper, providing a clear, shiny surface and improved strength.

"I have been using the XTC-3D High Performance Print Coating, and it has made my prints stronger and more visually appealing. It's a simple and effective way to enhance the durability of 3D prints." - Satisfied user (source)

Conclusion

By implementing the techniques and strategies discussed in this comprehensive guide, you can significantly improve the strength and durability of your 3D prints. From drying filament to choosing stronger materials and optimizing print settings, each step plays a crucial role in achieving high-quality, robust prints. Additionally, post-processing techniques like annealing, electroplating, and epoxy coating offer further opportunities to strengthen your prints and enhance their overall performance. With the knowledge gained from this guide, you can confidently create 3D prints that not only look great but also stand the test of time.

Remember, the key to successful 3D printing lies in experimentation, continuous learning, and staying up-to-date with the latest advancements in the field. So, roll up your sleeves, dive into the world of 3D printing, and enjoy the journey toward stronger and more impressive creations.