Gravity Die Casting Mould Material is an essential component for die casting and is one of the most important factors for achieving a successful outcome. It is used to create the casting mould that will shape and form the metal component. This material is typically made from a combination of metals, such as aluminium, copper, magnesium, steel, and zinc. The metals used must be chosen carefully to ensure the best possible results and to avoid the possibility of cracking or distortion of the moulds.

Gravity Die Casting Mould Material is also known as high pressure die casting or injection moulding. It is a process that involves injecting molten metal into a mould cavity at high pressure and temperature. The mould is created by using a die that is made from a combination of metals. This die must be strong enough to withstand the high pressure and temperature of the molten metal, while still allowing the metal to flow into the mould and create the desired shape.

When choosing a Gravity Die Casting Mould Material, it is important to consider the durability, strength, and versatility of the material. Aluminium is a popular choice because it is lightweight, strong, and very resistant to corrosion and wear. However, it is important to consider the other metals in the die as well, such as copper, magnesium, steel, and zinc. Each metal has its own characteristics that can affect the outcome of the casting process.

In addition to the metal components, the Gravity Die Casting Mould Material must also be chosen for its ability to withstand the high pressure and temperature of the molten metal. Specialised die casting tool steel is often used for this purpose. This steel is designed to be resistant to heat, wear, and corrosion, and it is also able to withstand high temperatures.

The Gravity Die Casting Mould Material must also be selected for its ability to allow the molten metal to flow freely and to create the desired shape. This is achieved by using a combination of metals that have different properties and melting points. For example, aluminium is a good choice for creating fine details, while copper is better for creating larger components.

Gravity Die Casting Mould Material is an important part of the die casting process and should be carefully selected for the best possible results. It is important to consider the characteristics of each metal, as well as the desired shape and size of the component. By choosing the right Gravity Die Casting Mould Material, manufacturers can ensure that their products are of the highest quality and are

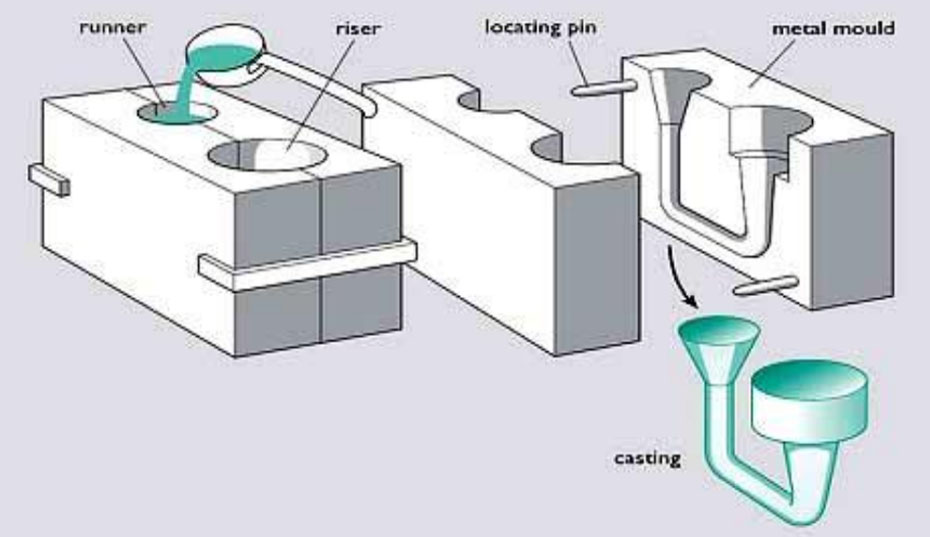

Gravity die casting mould material is a type of metal alloy used in industrial manufacturing processes. It is used to produce parts or components with complex shapes and high accuracy. The process involves injecting molten metal into a mould, which is then cooled and solidified to form the desired shape. In this article, we will discuss what gravity die casting mould material is, its types, advantages, and disadvantages, and how to choose the right material for your needs. We will also discuss the cost of gravity die casting mould material and the common mistakes to avoid when working with it. Finally, we will explore some best practices for working with gravity die casting mould material.

What is Gravity Die Casting Mould Material?

Gravity die casting mould material is a metal alloy used for industrial manufacturing processes. It is used to form components and parts with complex shapes and high accuracy, such as engine parts, electronic components, and many more. This type of material is used in die casting processes, as it can be easily injected into a mould, cooled, and solidified to form the desired shape. It is also known as gravity die casting or GDC material.

Gravity die casting mould material is composed of various metal alloys, such as aluminum, zinc, magnesium, and copper. Each metal type has its own advantages and disadvantages and should be chosen according to the application. For example, aluminum has a high melting point, making it ideal for high-temperature applications. On the other hand, zinc is more malleable and can be easily shaped into complex shapes.

Types of Gravity Die Casting Mould Materials

There are several types of gravity die casting mould materials available. The most common types are aluminum, zinc, magnesium, and copper alloys. Each type of material has its own advantages and disadvantages, and should be selected according to the application.

Aluminum alloys are the most commonly used in die casting, as they have a high melting point and offer excellent corrosion resistance. Aluminum alloys also offer good thermal and electrical conductivity, making them suitable for a wide range of applications.

Zinc alloys are also popular in die casting, as they offer excellent malleability and can be easily shaped into complex shapes. Zinc alloys also offer good corrosion resistance and are relatively low-cost compared to other metals.

Magnesium alloys are also used in die casting, as they offer excellent strength and weight ratio. Magnesium alloys are lightweight and can be used in applications that require lightweight components.

Finally, copper alloys are also used in die casting, as they offer excellent thermal and electrical conductivity. Copper alloys are also highly corrosion-resistant and are relatively inexpensive compared to other metals.

Advantages of Using Gravity Die Casting Mould Material

Gravity die casting mould material has several advantages over other types of materials. These include:

- Cost-effectiveness: Gravity die casting mould material is relatively inexpensive compared to other metals, making it a cost-effective choice for many applications.

- High accuracy: Gravity die casting mould material can be used to produce components with high accuracy, as it is easily injected into a mould and cooled to form the desired shape.

- Strength: Gravity die casting mould material is strong and durable, making it suitable for heavy-duty applications.

- Corrosion resistance: Gravity die casting mould material is highly corrosion-resistant, making it ideal for use in applications where corrosion is a concern.

- Lightweight: Gravity die casting mould material is lightweight compared to other types of materials, making it ideal for applications where weight is a concern.

Disadvantages of Using Gravity Die Casting Mould Material

Although gravity die casting mould material has several advantages, there are also some disadvantages to consider. These include:

- Low melting point: Gravity die casting mould material has a low melting point compared to other metals, making it unsuitable for high-temperature applications.

- Limited shapes: Gravity die casting mould material can only be used to produce components with limited shapes, as it is difficult to inject the molten metal into complex moulds.

- High shrinkage rate: Gravity die casting mould material has a high shrinkage rate, meaning that it shrinks as it cools, resulting in a slightly different shape than the mould.

- Poor electrical conductivity: Gravity die casting mould material has poor electrical conductivity compared to other metals, making it unsuitable for applications that require electrical conductivity.

Factors to Consider When Selecting Gravity Die Casting Mould Material

When selecting the right gravity die casting mould material for your application, there are several factors to consider. These include:

- Application: The type of application should be taken into consideration when selecting the right material, as different materials offer different properties and are suitable for different applications.

- Cost: The cost of the material should also be taken into account, as some materials are more expensive than others.

- Durability: The durability of the material should also be considered, as some materials are more durable than others.

- Corrosion resistance: The corrosion resistance of the material should also be taken into account, as some materials are more resistant to corrosion than others.

- Thermal conductivity: The thermal conductivity of the material should also be taken into consideration, as some materials are better conductors of heat than others.

How to Choose the Right Gravity Die Casting Mould Material

When choosing the right gravity die casting mould material, it is important to consider the application, cost, durability, corrosion resistance, and thermal conductivity of the material. It is also important to consider the complexity of the mould and the desired accuracy of the component. Once you have considered all of these factors, you can select the right material for your application.

Best Practices for Working with Gravity Die Casting Mould Material

When working with gravity die casting mould material, there are several best practices that should be followed to ensure the quality of the finished product. These include:

- Maintaining the temperature of the mould: It is important to maintain the temperature of the mould to ensure the molten metal does not cool too quickly, resulting in a poor-quality product.

- Cleaning the mould: It is important to clean the mould before every use to ensure that no contaminants are present, which can affect the quality of the finished product.

- Inspecting the mould: It is important to inspect the mould regularly to ensure that no defects are present, which can affect the quality of the finished product.

- Testing the product: It is important to test the finished product to ensure that it meets the desired specifications.

Cost of Gravity Die Casting Mould Material

The cost of gravity die casting mould material depends on the type of material and the quantity required. Generally, aluminum alloys are the most economical, followed by zinc and magnesium alloys. Copper alloys are the most expensive.

Common Mistakes to Avoid When Working with Gravity Die Casting Mould Material

When working with gravity die casting mould material, it is important to avoid common mistakes that can lead to poor-quality products. These include:

- Not maintaining the temperature of the mould: If the mould is not maintained at the correct temperature, it can result in a poor-quality product.

- Not cleaning the mould: If the mould is not cleaned regularly, it can lead to defects in the finished product.

- Not inspecting the mould: If the mould is not inspected regularly, it can lead to defects in the finished product.

- Not testing the product: If the product is not tested, it can lead to defects in the finished product.

Conclusion

Gravity die casting mould material is a metal alloy used for industrial manufacturing processes. It is used to form components and parts with complex shapes and high accuracy. There are several types of gravity die casting mould materials available, such as aluminum, zinc, magnesium, and copper alloys. Each type of material has its own advantages and disadvantages and should be selected according to the application. Gravity die casting mould material has several advantages, including cost-effectiveness, high accuracy, strength, corrosion resistance, and lightweight. However, there are also some disadvantages, such as a low melting point, limited shapes, and a high shrinkage rate. When selecting the right material, it is important to consider the application, cost, durability, corrosion resistance, and thermal conductivity of the material. It is also important to follow best practices when working with gravity die casting mould material, such as maintaining the temperature of the mould, cleaning the mould, inspecting the mould, and testing the product. The cost of gravity die casting mould material depends on the type of material and the quantity required, and it is important to avoid common mistakes that can lead to poor-quality products.