Most Injection Molding Failures Begin in Design, Not on the Shop Floor

Everything looks calm at first. Schedules are approved, samples are signed off, and everyone is confident the shipment will move on time. The assumption is simple: the hard work is done.

Then the first fault appears. A dimension drifts. An insert no longer sits correctly. A casing shows stress where none was expected. What felt stable suddenly behaves differently, and by the time the issue becomes visible, tooling is complete, timelines are locked, and options are limited.

What follows is familiar: urgent meetings, production pauses, and a growing realization that it is now too late to fix what should have been identified earlier. This is the moment where serious buyers separate themselves from everyone else.

Serious buyers do not treat this as bad luck.

They ask a harder question: Why was this risk not exposed earlier?

Why Late Failures Always Land on Someone’s Desk

Every unstable precision component eventually lands on someone’s desk for explanation. The pressure feels different depending on the role, but the responsibility is always real.

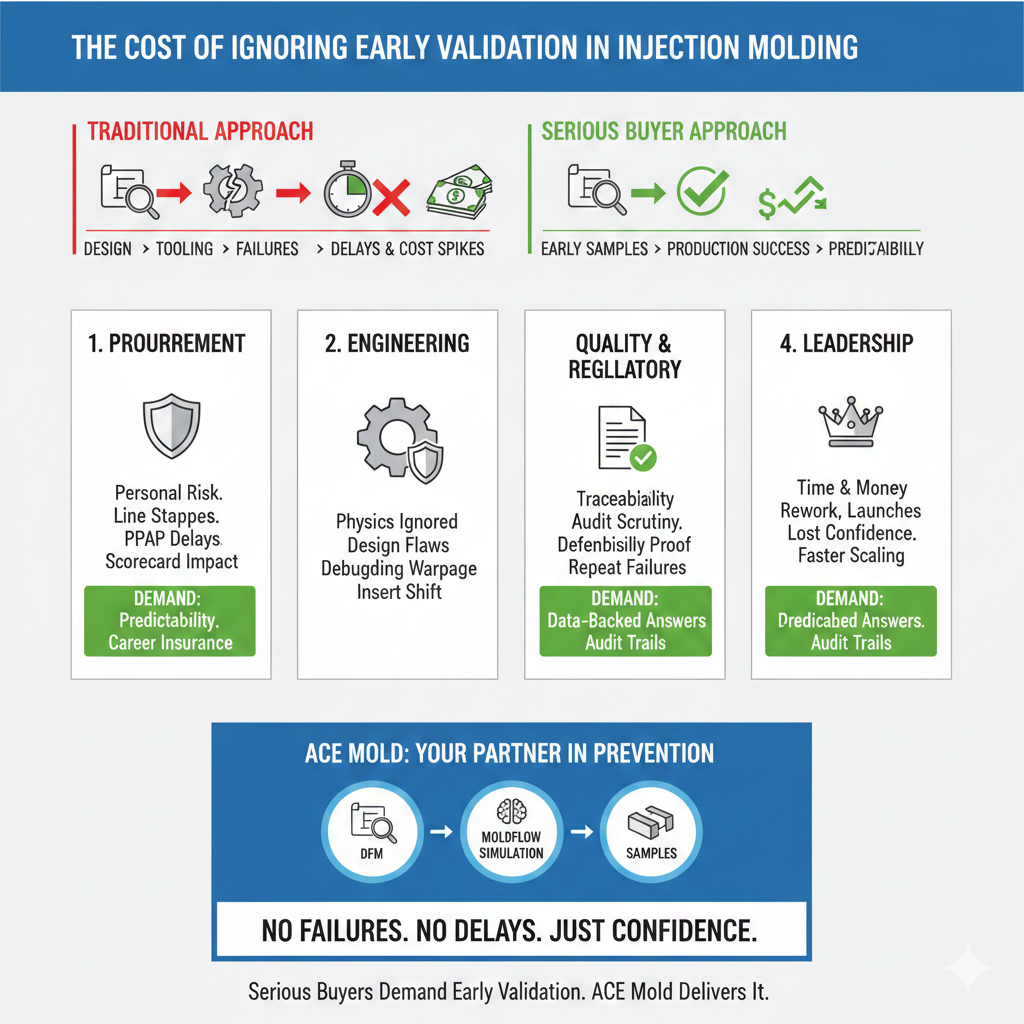

1. Procurement and Sourcing Leaders

Their pain is personal risk.

Procurement teams are measured by outcomes, not effort. When a precision component fails, the issue is rarely isolated to the part. It reflects back on the sourcing decision.

What they worry about:

- Line stoppages traced to a supplier choice

- PPAP delays that damage KPIs

- Supplier scorecard impacts they must explain

- The question no one wants to answer: Why didn’t we catch this earlier?

Why early validation samples matter to them:

- Predictability instead of firefighting

- Fewer escalations and emergency calls

- Clear proof they can defend decisions

For procurement, early validation is not a bonus. It is career insurance.

2. Engineering and Manufacturing Teams

Their pain is physics being ignored.

Engineers know the truth. Most injection molding failures are not random. They are designed in.

What frustrates them:

- Designs approved without manufacturability input

- Production blamed for problems locked in months earlier

- Debugging warpage, shrinkage, or insert shift after tooling

Why DFM and Moldflow simulation resonate:

- Flow, cooling, and shrinkage behavior revealed early

- Insert movement predicted instead of guessed

- Fewer late-stage root cause investigations

Engineers do not want promises.

They want problems solved digitally before steel is cut.

3. Quality, Regulatory, and Compliance Teams

Their pain is traceability and defensibility.

In regulated environments, failure is not only functional. It is documented.

What keeps them alert:

- Can we explain this to an auditor

- Can we prove dimensional stability in molded parts

- Do we have evidence this will not repeat

Why early validation matters:

- Physical samples supported by simulation data

- Documentation for FDA, ISO, and OEM reviews

- Less pressure during audits

Simulation and validation give quality teams answers, not excuses.

4. Leadership, Founders, and Program Owners

Their pain is time, money, and momentum.

For decision makers, late failures are business risks.

What they fear:

- Tooling rework

- Delayed launches

- Loss of investor confidence

- Programs slipping with no clear recovery path

Why early-stage rigor matters:

- Fewer resets

- Faster confidence to scale

- Predictable execution

They do not want manufacturing to become the risk.

Why Design Is Where Precision Is Won or Lost

Injection molding does not create problems. It exposes them.

Once geometry, wall thickness, gate locations, and insert placement are locked into a tool, the behavior of the part is largely fixed. Warpage, tolerance drift, and stress concentration do not appear by accident. They emerge because the design allowed them to.

Without injection molding failure prevention at the design stage:

- Problems surface after tooling

- Changes become expensive

- Schedules absorb the damage

Serious buyers understand this. They do not wait for production to reveal issues.

They insist on finding them early.

How Precision Components Fail When Design Risks Are Ignored

Serious buyers do not think in categories. They think in total risk.

- Precision bearing housings fail when cooling imbalance causes ovality, leading to noise, vibration, or assembly resistance

- Insert-molded components fail when metal inserts shift by fractions of a millimeter during flow, disrupting automated assembly

- Medical plastic casing molding often appears acceptable until sterilization introduces cracks caused by built-in stress

- Electroplated circular bases lose roundness after plating when shrinkage and material flow were never simulated

- Sterilization-safe plastic components fail when material behavior under heat and pressure was assumed instead of validated

These are not manufacturing mistakes. They are design-stage decisions that surface later.

Why Serious Buyers Demand Early Validation and Simulation

Buyers who have experienced late failures learn one lesson quickly. Prevention costs less than correction.

They demand:

- DFM to challenge manufacturability early

- Moldflow simulation to understand real material behavior

- Early validation samples to confirm stability before volume production

This approach does not slow programs down. It keeps them from breaking later.

Where ACE Mold Shares the Responsibility

ACE Mold is built around one principle. Risk should be addressed while it is still fixable. By combining DFM, Moldflow simulation, and early validation samples, ACE Mold identifies and removes design-stage risks that commonly lead to:

- Warpage

- Insert movement

- Tolerance drift

- Post-processing deformation

This stabilizes precision components across applications, including:

- Bearing housings

- Insert-molded parts

- Medical casings

- Circular bases

Early validation samples allow teams to test, measure, and verify performance under real conditions. Reliable, on-time delivery then protects schedules once production begins.

No failures. No delays. Just modelling, samples, and on-time delivery.

Why This Approach Matters to Serious Buyers

Serious buyers are not looking for reassurance after problems occur.

They want confidence before production begins.

So They value:

- Predictability over speed

- Clarity over assumptions

- Engineering discipline over last-minute fixes

They know the calmest programs are the ones where risks were handled early, quietly, and deliberately.

That is why early validation and simulation are not optional for serious buyers of precision components.

And that is exactly where ACE Mold fits — not as a vendor reacting to problems, but as a partner sharing responsibility before problems exist.