Plastic Molding for China Becomes a Revolutionary Industry

Plastic Molding for China has become a popular business. The plastic industry has finessed to unreachable heights. Have a look around; you are likely to spot a plastic material. Humans have shifted from other durable materials to plastic is simple; plastic is economical and an all-purpose material. Unlike Gold and Steel, plastic is something that we can carry around with us at all times.

Also, the misconception that plastic is the only leading cause of pollution is wrong. The real cause of pollution is human behavior when it comes to recycling. Recycling and plastic go hand in hand.

You May Also Read: The Main Components of China Plastic Injection Molding

Perhaps plastic molding is China’s leading industry for its advanced production capacities. China is the world’s leading exporter, and Chinese products are renowned for their high-quality standards. China was the first country to explore plastic injection molding. Plastic Injection Molding has since then extended out like wild-fire.

Moreover, plastic Molding factories are continually turning their wheels to produce new shapes and sizes. Providing the best plastic molded products is the sole aim of any injection molding factory. Plastic molding does not limit itself to big machinery. You can mold your own plastic buttons at home, that too, with beginner tools.

Injection Plastic Molding for China Becomes Mainstream

Injection Molding is a relatively new area in plastic manufacturing; hence it already has advanced features. Previously, producing parts in bulk was a dream. Producing a batch of molded parts under a set time is an achievement in itself. Apart from injection molding, other forms of plastic molding exist, for instance, vacuum forming, silicone molding, extrusion molding, and blow molding.

More importantly, china molding companies offer free design analysis. Every plastic molded part is based on a designed model. Chinese companies effectively hire a designer to create 3D models. 3D printing has altered the designing strategies of parts. With the help of 3D printers, you can create a prototype for your plastic part. With the printing process in place, any errors get identified before mass production.

Strategically placed plastic molding factories cater to hundreds of orders. Almost all injection molding factories follow mass production. Almost all products undergo a rigorous production process with no room for error.

Producing cost-effective parts at a massive pace comes with its challenges. You might be wondering what all the hype around injection bolding is about. We have taken the liberty to illustrate some advantages of injection molding over other processes in steps below:

- Speedy and highly efficient production process: Produces more than 100 parts per day. Productivity depends on working hours.

- Automated manufacturing: The labor costs are next to nothing since the entire process is entirely automated

- Ability to choose diverse material: Different parts have different compositions. Some people prefer pure plastic resin.

- Solider finished parts: Plastic parts that have a more substantial exterior than other molded plastic products.

- Post-Production Process Ceased: The post-production process is time-consuming at the worst, and most products get lost in the way.

The Chinese way of Doing things in Plastic Molding

Plastic molding for China-based manufacturers is a creative area. Chinese companies are dedicated to providing state of the art plastic parts and intend to reduce time wastage while doing so. The molding process begins way before the raw materials enter the manufacturing site. A tremendous amount of planning takes place in selecting the resin.

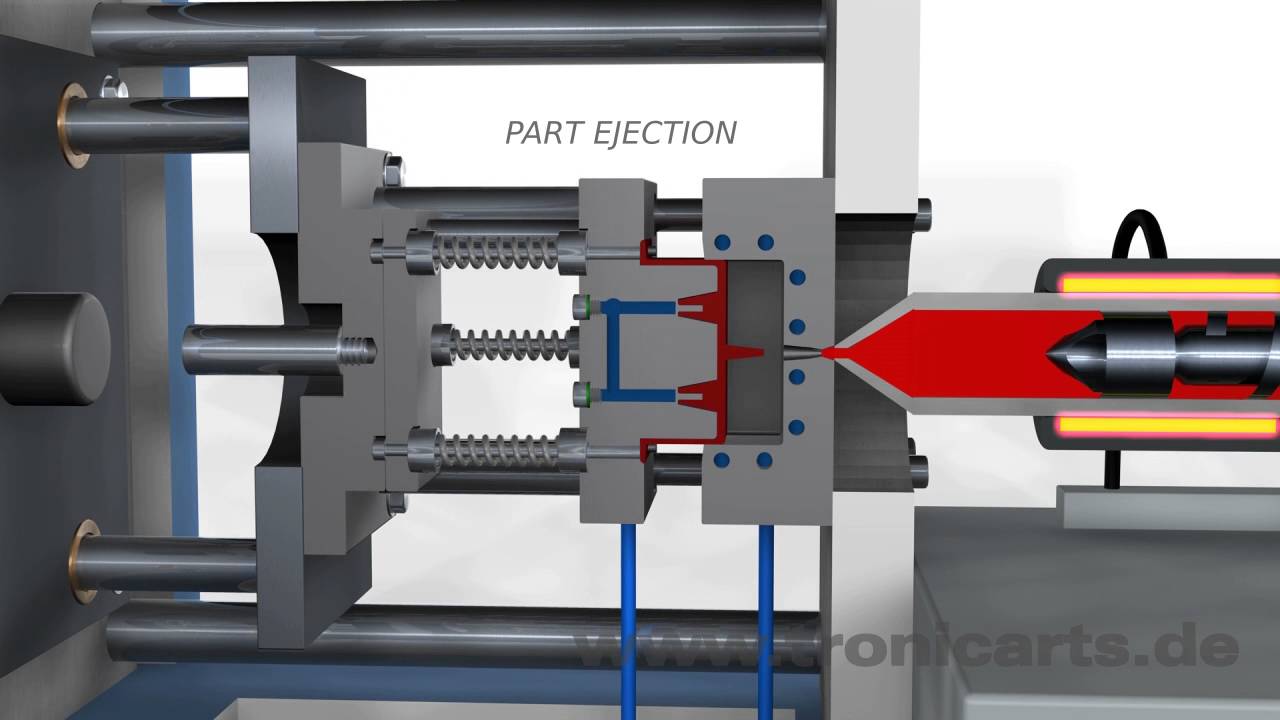

Then, the liquid resin undergoes an extensive prepping process before it enters the molding machine. Any sign of impurity can sabotage the whole production process. After entering the molding machine, every subsequent step is the job of the machine. As the name suggests, liquid resin is “injected” in the molds.

Most molds are made before the molding process; a standard molding design is created for mass production. As soon as the heated molten resin is injected, the solidifying process starts. Freezing the mold in place allows it to cool off. The way molds open look very visually pleasing.

If you ever have the chance to see a mold opening, you will notice that the experience is magical. The satisfaction of seeing a mold form before your very eyes have a visual ASMR effect. The molding procedure does not come to a halt after the mold is formed. The mold has to undergo extensive chemical treatments before they reach the consumer.

China is exploring new boundaries within plastic molding manufacturing. A few Chinese companies have launched in-built 3D printers in their molding machines. A prototype mold re-invents the way molds are perceived. Chinese manufacturers continue to set a standard for the industry with their innovation and modernism.

The Inner Workings of a Plastic Molding Machine

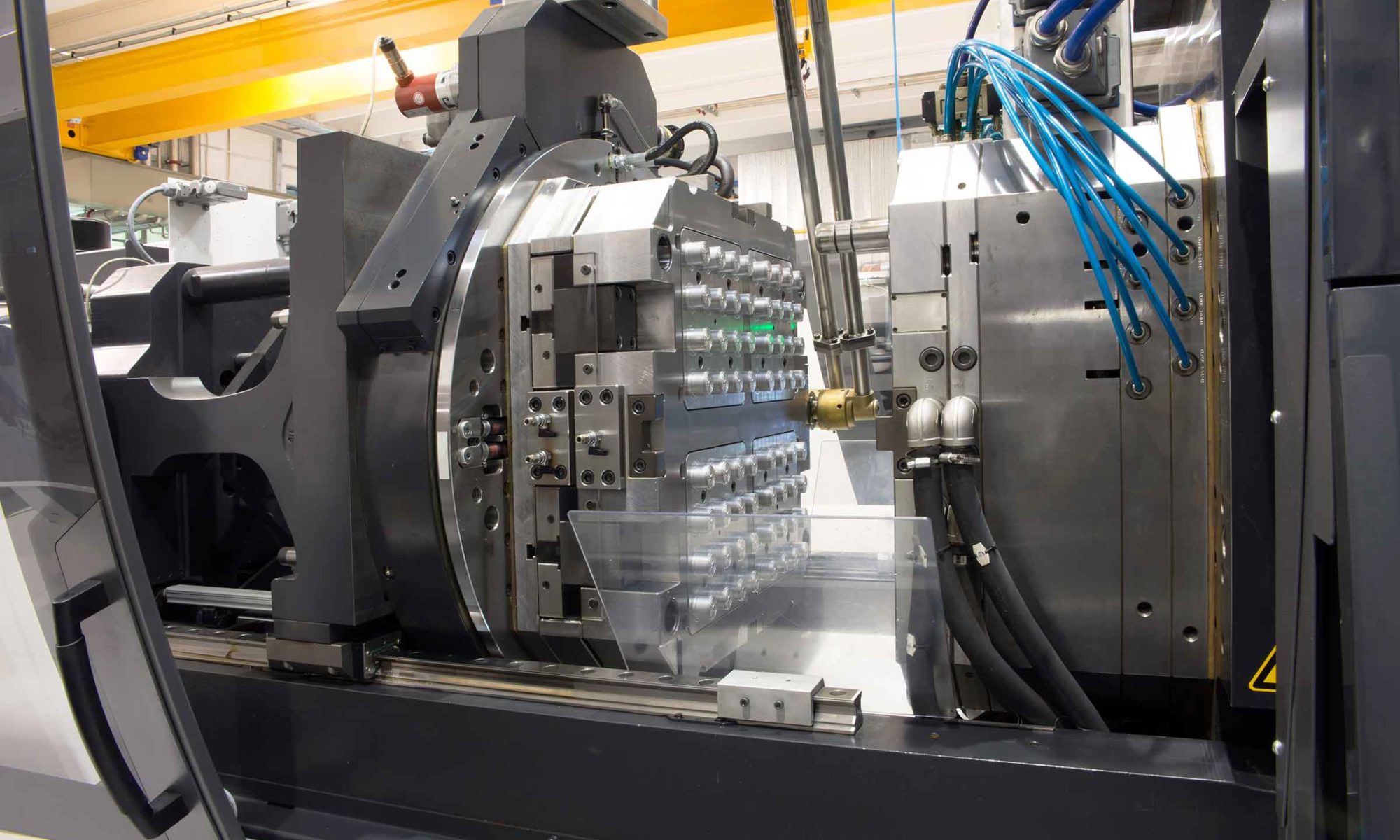

A plastic molding machine does not come cheap. Machinery is an expensive investment; there is no doubt in it. If you think machinery is expensive, the maintenance cost will blow you away. The general perception is that buying a machine and handling the machine are two different money drenchers. It is safe to say that purchasing a plastic molding machine is accompanied by a lot of research.

Every search is incomplete without a check-list. You are not buying a piece of clothing from a thrift shop; there are no refunds; therefore, choose wisely. Understanding the parts of a plastic molding machine is essential before buying it. The existence of these parts determines the future output of the machine. A plastic molding machine should have some of the following features:

- High performance and Energy-Saving Components

- Horizontal Structure

- An ergonomic size that fits a standard place

- Applicable in industries like food and beverages or medical at the same time

- Electric Molding Machines should have a voltage bracket

- Motion Control system to make injection accuracy up to 0.001 mm

- A user-friendly capacitive touch screen

- Intelligent Mold Clamp

- High-Speed Toggle Mechanism

Emerging Techniques in Transforming Plastic

Technology is thriving in a supportive market; there is a new way to do everything. Similarly, the plastic molding process is seeing new techniques shape up after a few years. Recently FRP molding highlights itself as a torch in plastic molding. In simple terms, this is an attempt to make fiberglass by molding plastic.

Moreover, Plastic Molding changed since it started. The first few molds trace back to clay models. Molding began in the early times. The basis of advanced technology is our old survival systems. The concept of molding has evolved over the centuries.

Indeed, plastic molding techniques are changing for the better. Integrating new methods offers a new perspective to low scale manufacturers. Resources do not limit imagination.

Take Away

Preparing the perfect mold is a constructive process. Every plastic mold manufacturer realizes the impact his product has on society and the environment. Humans should not take the atmosphere for granted while making ground-breaking advancements. Every product has a product life cycle. Recycling should be the end stage of any disposable plastic product.

Plastic Mold making has attained extraordinary production standards. Some would even say that there is no going beyond the technology in place today. Plastic Molding for China continues to inspire producers and manufacturers.

Would you like to see a professional plastic mold making process carried out? Have a look at this website.

You May Also Read: How Do Injection Parameters Influence the China Plastic Molding Man...