ABS (Acrylonitrile Butadiene Styrene) plastic is a thermoplastic polymer commonly used in the manufacturing of toys, electronics, automotive parts, and household items. Injection molding is a manufacturing process used to produce parts by injecting a melted material into a mold cavity. ABS plastic is frequently used in injection molding due to its toughness, rigidity, and heat-resistant properties. The process involves heating the ABS plastic to a high temperature until it melts and then injecting it into a mold under high pressure. The melted plastic cools and solidifies within the mold, taking the shape of the mold cavity. The mold is then opened, and the molded part is removed.

ABS plastic injection molding is an innovative process that has been used to create a wide variety of items over the past few decades. Injection molding is a process in which molten plastic is injected into a mold at high pressure to form a shape. It is an extremely versatile technique that has enabled manufacturers to produce complex shapes in a wide range of sizes. In this article, we will explore what ABS plastic injection molding is, the benefits it offers, the process of injection molding, the materials used, the applications of ABS plastic injection molding, the future of this technology, and courses that can help you learn more about the process.

What is ABS Plastic Injection Molding?

ABS plastic injection molding is a process that involves injecting molten plastic into a mold to create a desired shape. It is a highly efficient manufacturing process that can be used to produce a wide variety of items, from consumer goods to automotive parts. The injection molding process begins with the heated plastic being injected into the mold cavity at high pressure. The plastic then cools and hardens to the desired shape. The injection mold can then be removed from the mold and the part is ready for use.

The ABS plastic injection molding process has been used for decades to manufacture a wide range of products. It is one of the most popular processes for producing plastic parts because of its versatility and cost-effectiveness. Injection molding is a great way to produce parts quickly and accurately, and it can be used to make products in almost any shape and size.

Benefits of ABS Plastic Injection Molding

ABS plastic injection molding offers a number of benefits for businesses. It is a cost-effective process that can be used to produce a wide range of parts and products quickly and accurately. The process is also highly energy-efficient, which helps to reduce the environmental impact of manufacturing. In addition, injection molding is a scalable process, meaning that it can be used to produce a wide range of parts in different sizes and shapes. This makes it an ideal process for businesses looking to produce a variety of parts or products.

Injection molding also offers increased accuracy and consistency when compared to other manufacturing processes. The process eliminates human error and ensures that every part or product produced is consistent in quality. In addition, injection molding produces parts with minimal waste, which helps to reduce the overall cost of production.

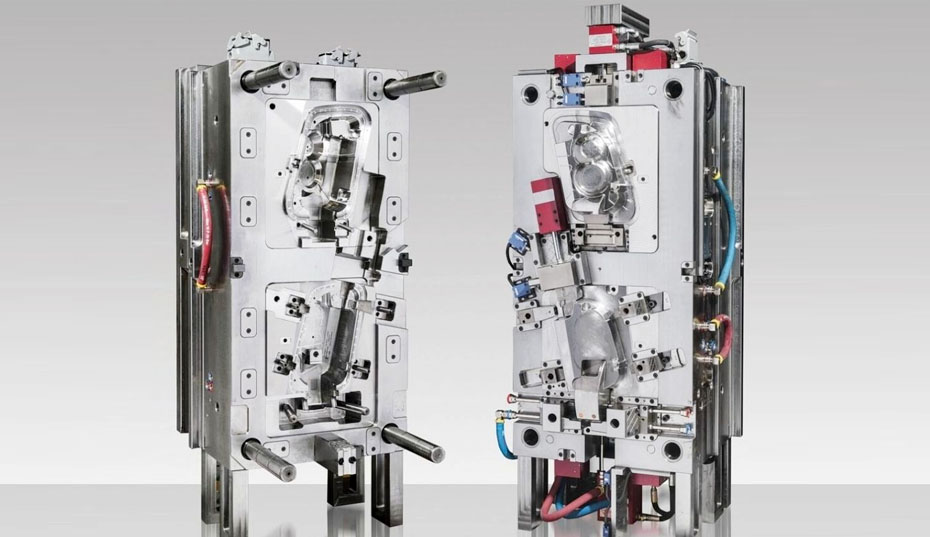

The ABS Plastic Injection Molding Process

The injection molding process begins with the mold being placed in the injection molding machine. The plastic is then heated to a molten state and injected into the mold at high pressure. The plastic then cools and hardens to the desired shape. The mold can then be removed from the mold and the part is ready for use.

Injection molding can be used to produce a wide range of parts and products in a variety of sizes and shapes. The process is highly efficient and can produce parts quickly and accurately. In addition, injection molding offers increased accuracy and consistency when compared to other manufacturing processes.

Benefits of ABS Plastic Injection Molding for Businesses

ABS plastic injection molding is an ideal process for businesses looking to produce a wide range of parts or products quickly and accurately. The process is highly efficient and can be used to produce parts in a variety of sizes and shapes. In addition, the process is highly energy-efficient, which helps to reduce the environmental impact of manufacturing.

Injection molding is also a cost-effective process that can help businesses reduce their overall production costs. The process eliminates human error and ensures that every part or product produced is consistent in quality. In addition, injection molding produces parts with minimal waste, which helps to reduce the overall cost of production.

Challenges of ABS Plastic Injection Molding

Although the ABS plastic injection molding process offers a number of benefits, there are also some challenges associated with the process. One of the main challenges is the high cost of the molds used in the process. Injection molds can be expensive to produce and require specialized equipment to operate. In addition, the process requires a high level of skill and expertise, which can add to the overall cost of production.

The injection molding process is also limited by the size and shape of the parts that can be produced. The process is not suitable for producing small parts or parts with complex shapes. In addition, the process is limited by the type of plastic that can be used. Not all plastics are compatible with the injection molding process, so it is important to select the right material for the job.

ABS Plastic Injection Molding Materials

ABS plastic injection molding is a versatile process that can be used to produce a wide variety of parts and products. The process can be used with a variety of materials, including ABS plastic, polycarbonate, nylon, and polypropylene. Each type of material has its own unique properties and benefits, so it is important to select the right material for the job.

ABS plastic is one of the most popular materials used in the injection molding process. It is a thermoplastic material that is lightweight, durable, and resistant to corrosion and chemicals. It is also easy to mold and can be used to produce a wide range of parts and products.

Applications of ABS Plastic Injection Molding

ABS plastic injection molding is an extremely versatile process that has a wide range of applications. The process can be used to produce a variety of parts and products, from consumer goods to automotive parts. In addition, the process can be used to produce medical components, toys, and even furniture. The process is also used to produce a wide range of packaging materials, including bottles and containers.

The process is also used to produce a wide range of industrial components, such as valves, fittings, and gaskets. In addition, the process can be used to produce electronic components, including circuit boards and connectors.

The Future of ABS Plastic Injection Molding

ABS plastic injection molding is a highly versatile process that has been used to produce a wide variety of parts and products for decades. The process is highly efficient and can be used to produce parts quickly and accurately. In addition, the process is energy-efficient, which helps to reduce the environmental impact of manufacturing.

The future of ABS plastic injection molding looks bright. The process is expected to continue to evolve and become even more efficient and cost-effective. In addition, the process is expected to be used to produce a wider range of parts and products, including medical components and electronic devices.

Courses on ABS Plastic Injection Molding

If you are interested in learning more about ABS plastic injection molding, there are a number of courses available online. These courses can provide an in-depth look at the process and the materials used in injection molding. They can also provide valuable insight into the challenges and opportunities associated with the process.

In addition, there are a number of books and resources available that can provide a more comprehensive look at the process of injection molding. These resources can provide valuable information on the materials used in injection molding, the process itself, and the challenges and opportunities associated with the process.

Conclusion

ABS plastic injection molding is an innovative process that has been used to produce a wide range of parts and products for decades. The process is highly efficient and can be used to produce parts quickly and accurately. In addition, the process is energy-efficient, which helps to reduce the environmental impact of manufacturing.

The process offers a number of benefits for businesses, including cost-effectiveness and increased accuracy and consistency. In addition, the process can be used with a variety of materials, including ABS plastic, polycarbonate, nylon, and polypropylene.

ABS plastic injection molding is an extremely versatile process that has a wide range of applications. The process is expected to continue to evolve and become even more efficient and cost-effective. If you are interested in learning more about ABS plastic injection molding, there are a number of courses and resources available that can provide valuable insight into the process.